Sports shoe spike manufacture method

A production method and technology for sports shoes, which are applied to shoe uppers, footwear, boot legs, etc., can solve the problems of high machine utilization, many labor, long cycle, etc., to ensure product quality, high processing efficiency, and low processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

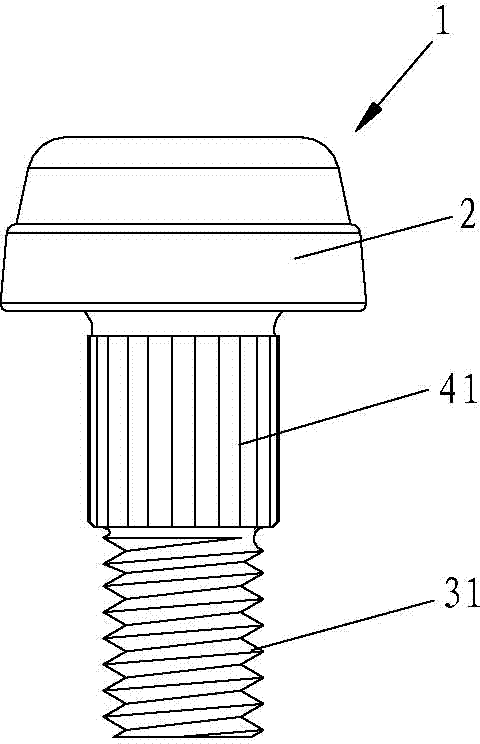

[0018] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~3 Shown, sports shoe stud manufacturing method of the present invention, it may further comprise the steps:

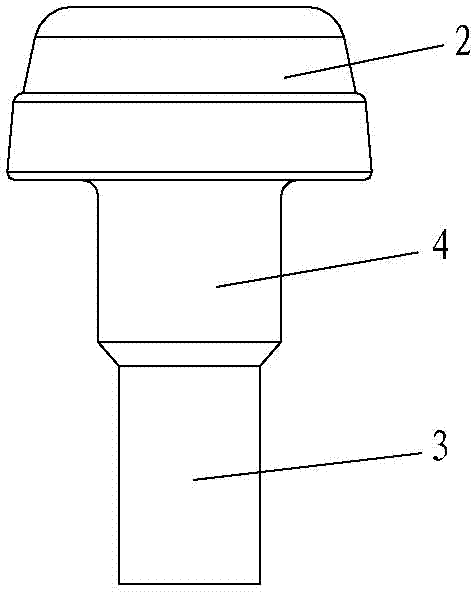

[0019] 1. Use a heading machine to forge the raw material to form a stud blank. The formed stud blank is composed of a spike cap 2, a screw post 3, and a flower post connected between the spike cap 2 and the screw post 3. 4, the screw column 3 and the flower column 4 are stepped structures with unequal diameters, the outer diameter of the screw column 3 is smaller than the outer diameter of the flower column 4, the outer diameter of the screw column 3 is 4.86~4.97mm, and the flower column The outer diameter of the tooth column 4 is 5.76~5.84mm;

[0020] 2. Grinding the rough embryos of shoe studs;

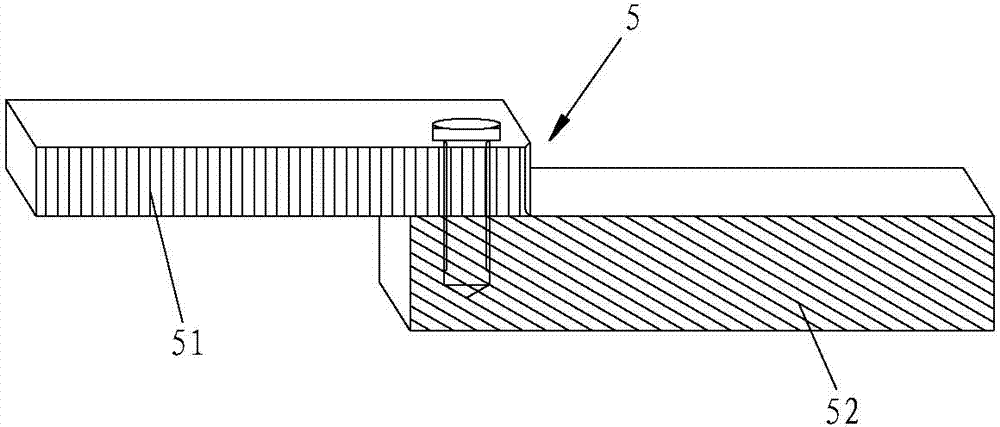

[0021] 3. Use the teeth rubbing jig 5 to rub the flower column 4 at one time to form a straight flower tooth 41 and rub the thread column 3 to form a thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com