Production method of surface conducting polymer graphic pattern

A kind of conductive polymer and polymer technology, applied in the direction of photoplate making process of pattern surface, optical mechanical equipment, nanostructure manufacturing, etc., can solve the problems of high cost and long time, and achieve mature technology, simple process and high production rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]The aniline monomer can be oxidatively polymerized into polyaniline under the condition of ferric chloride as an oxidizing agent, and can form a uniform film on the substrate. We added N-(3-trimethoxypropyl)pyrrole monomer to the polymerization system to copolymerize with aniline, which strengthened the adhesion ability of the polyaniline film to the substrate.

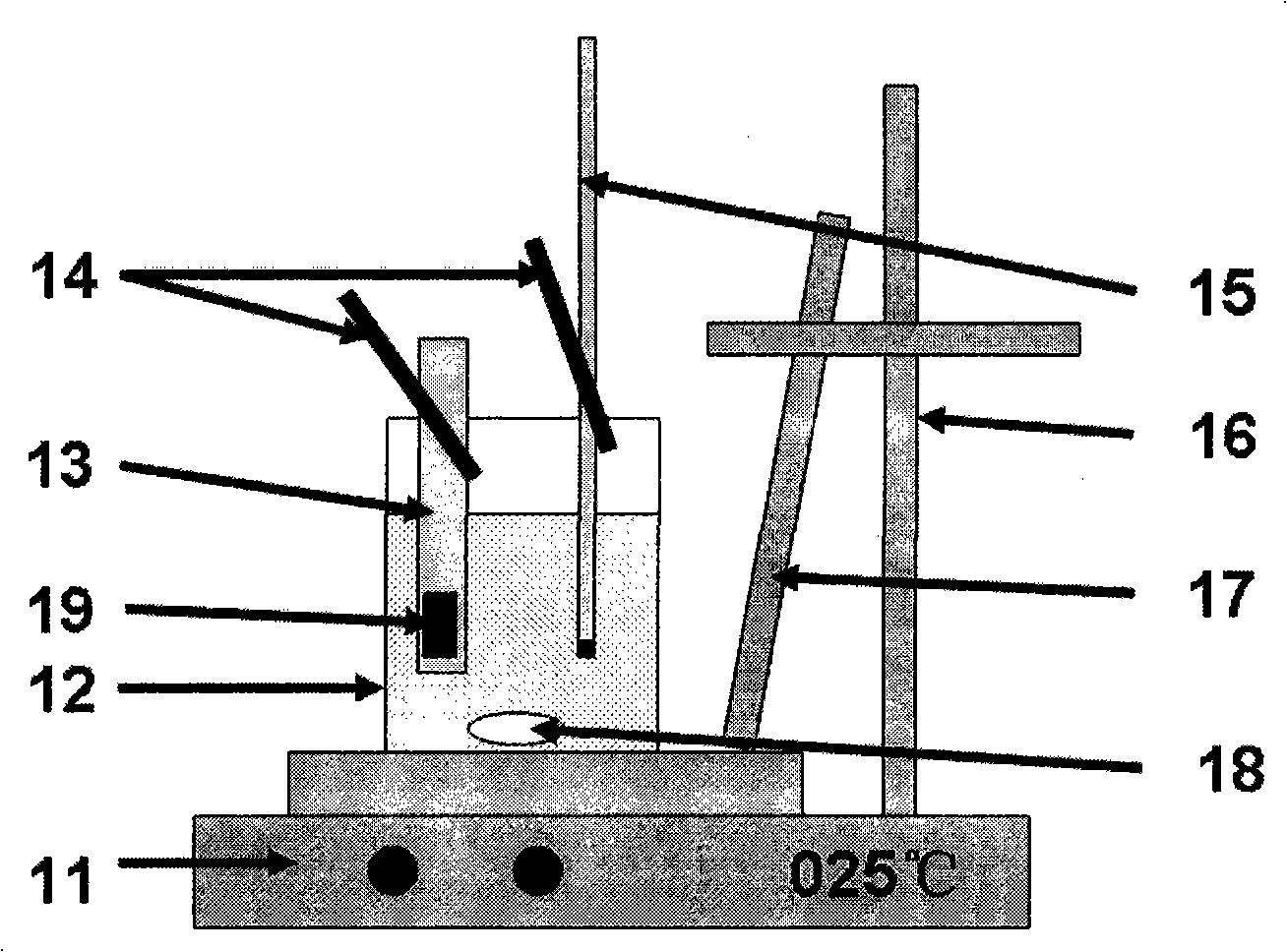

[0050] Preparation conditions of polyaniline film:

[0051] Aniline 1mL, N-(3-trimethoxypropyl)pyrrole monomer 40μL, iron trichloride 0.72g, temperature 25°C, time 10min.

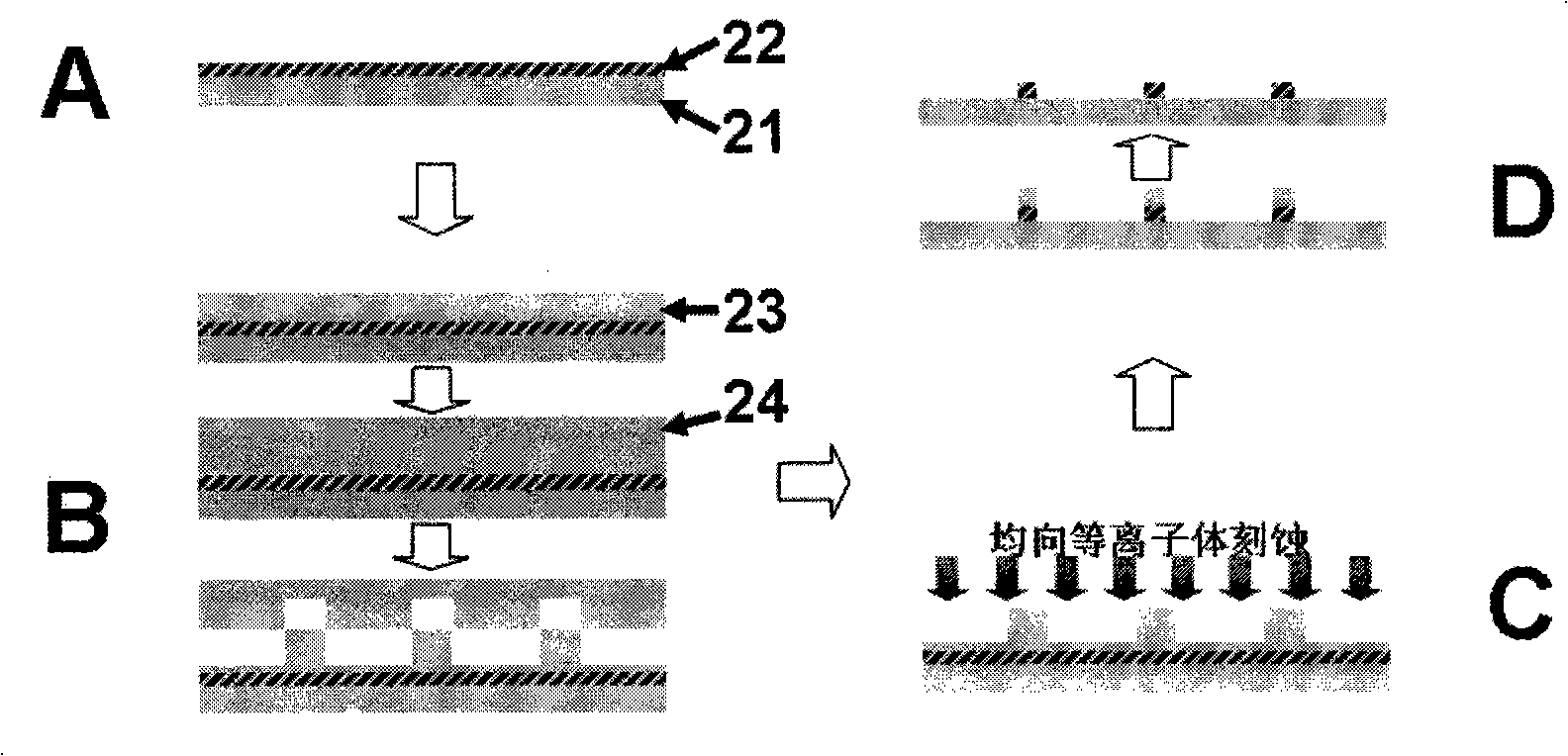

[0052] The morphology of polyaniline thin films was characterized by tapping mode of atomic force microscope, as image 3 shown. It can be seen from the figure that polyaniline can form a uniform film on the silicon dioxide substrate, the film thickness is 20nm, and the surface roughness is about 7.157nm. Then spin-coat PMMA film (400nm) on this layer of film, and anneal at 120°C for 5min. Imprinting uses a strip patterned silicon templat...

Embodiment 2

[0054] The polyaniline sample that is spin-coated with the PMMA thin film with the silicon template (such as the positive type (raised square pattern) pattern) that handles in embodiment 1 Figure 8 shown) for imprinting. The specific fluorination process of the silicon template is as follows: the surface of the template is treated with an oxygen plasma system, the oxygen flow rate is 120mL / min, the power is 300W, and the treatment time is 3 minutes; then the surface of the template is ultrasonically cleaned with high-purity water for 3 times, each time is 5 minutes , so that the surface was thoroughly cleaned; then the template was dried at 120°C for 1 h, and finally a layer of fluorosilylating reagent (perfluorodecyl-1, 1,2,2-Tetrahydro-trichlorosilane). The embossing conditions were controlled at a temperature of 170° C., a pressure of 50 bar, and a time of 500 s. like Figure 9 As shown, the sample is separated from the template after imprinting, and a "well" pattern th...

Embodiment 3

[0056] When the pyrrole monomer is used as an oxidizing agent in ferric chloride, a similar polymerization reaction can also occur to form a film.

[0057] Preparation conditions of polypyrrole membrane:

[0058] Pyrrole 400 μL, N-(3-trimethoxypropyl)pyrrole monomer 40 μL, ferric chloride 0.72 g, temperature 25° C., time 10 min.

[0059] Then spin-coat PMMA film (400nm) on this layer of film (its thickness is 20nm), and anneal at 120°C for 5min. The embossing conditions were controlled at a temperature of 170° C., a pressure of 50 bar, and a time of 500 s. A silicon template with a stripe pattern was used for imprinting, and its fluorination process was as in Example 1. After imprinting, the sample is separated from the template to obtain a band pattern that is completely complementary to the template structure. It is then etched with oxygen plasma. The etching conditions are controlled as an oxygen flow rate of 120ml / min, a power of 30W, and an etching time of 10min. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com