Press type air injection device

An air-jet device and press-type technology, which is applied in the direction of liquid variable-capacity machinery, piston pumps, tobacco, etc., can solve problems such as uneven tightness, heat loss, burnt smell, etc., to avoid local overheating, uniform heating, and avoid The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

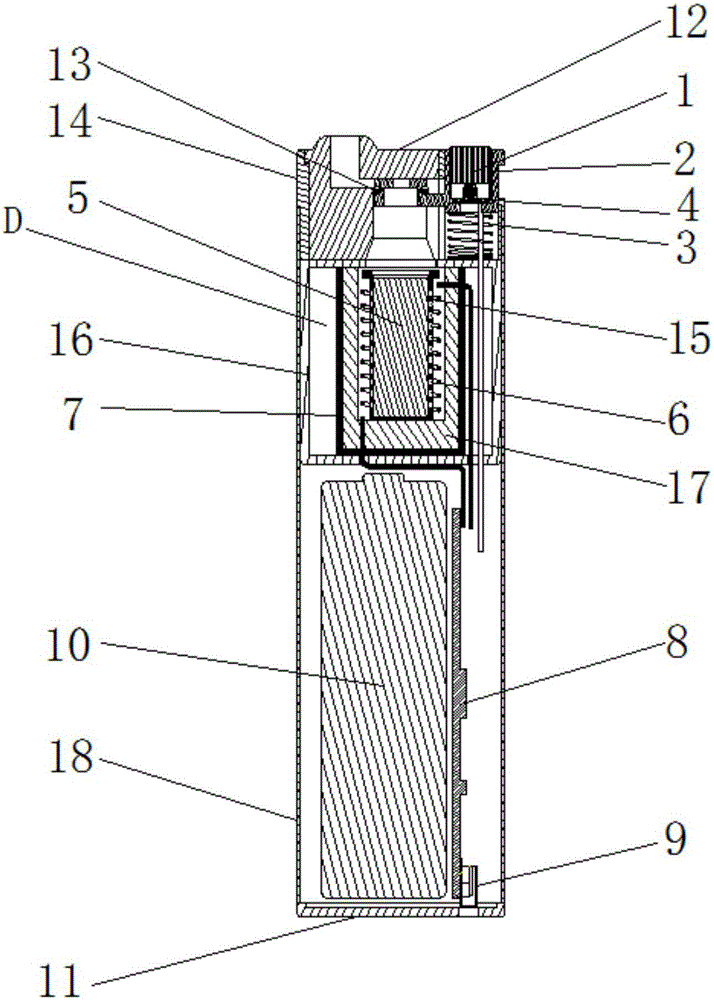

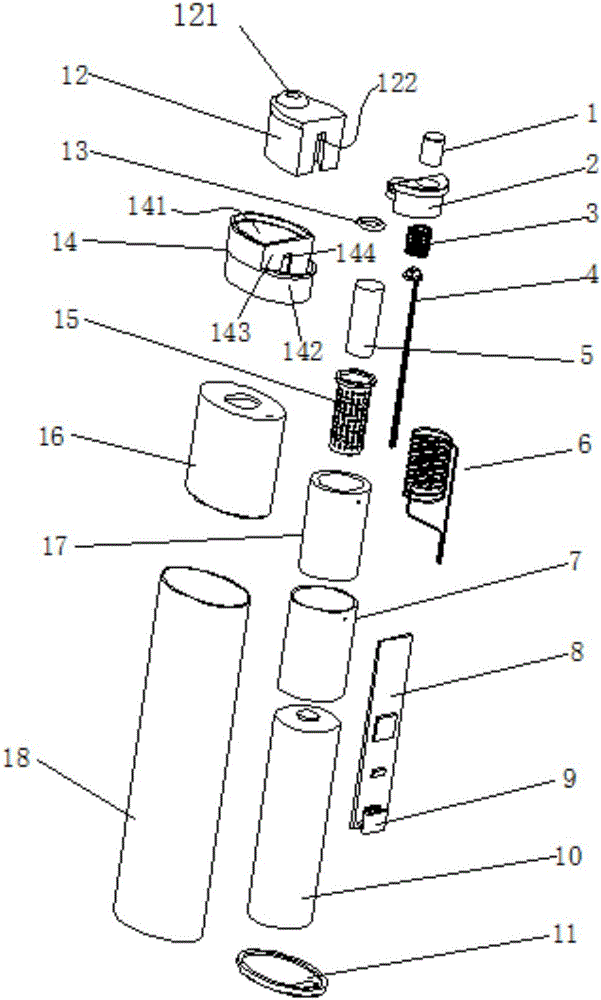

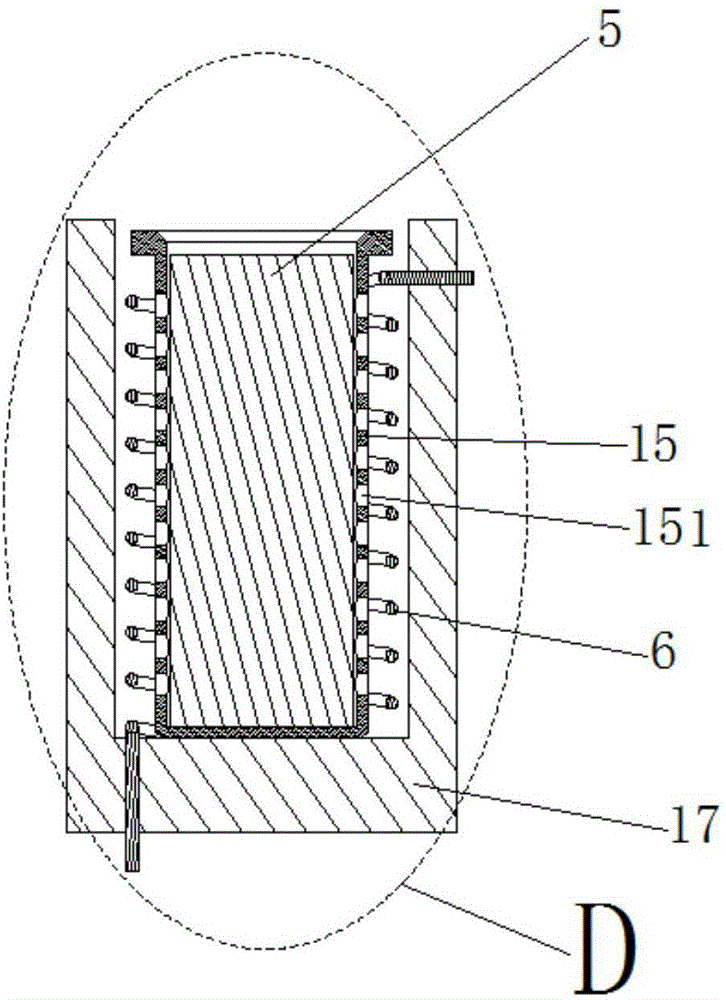

[0048] The overall structure of the push-nose-suction heated cigarette smoking set of the present invention has been described in the Summary of the Invention. figure 1 to attach Figure 4 Relevant parts and their structures can also be clearly displayed, so details will not be repeated.

[0049] The working process of the push-nose-suction heating type cigarette smoking set of the present invention is only described in conjunction with the accompanying drawings:

[0050] This smoking set is equipped with solid tobacco material that can be heated by baking and cracked to produce aroma substances. The solid tobacco material is a cylindrical cigarette with a special formula. The cigarette 5 is put into the cigarette heating tube 15 .

[0051] When the user only presses the heating start button 1 without pressing the piston bracket 2, the heating element 6 suspended between the cigarette heating chamber 15 and the heat insulating sleeve 7 starts to generate heat when the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com