A method for automatic calibration and accuracy verification of the roll gap of the coiler auxiliary roll

A precision verification and automatic calibration technology, applied in the field of calibration, can solve the problems such as the inability to realize the automatic calibration of the roller gap, restrict the normal production and operation of the site, and the long time-consuming of the auxiliary roll, so as to save manual measurement time and eliminate Unsafe factors, the effect of facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

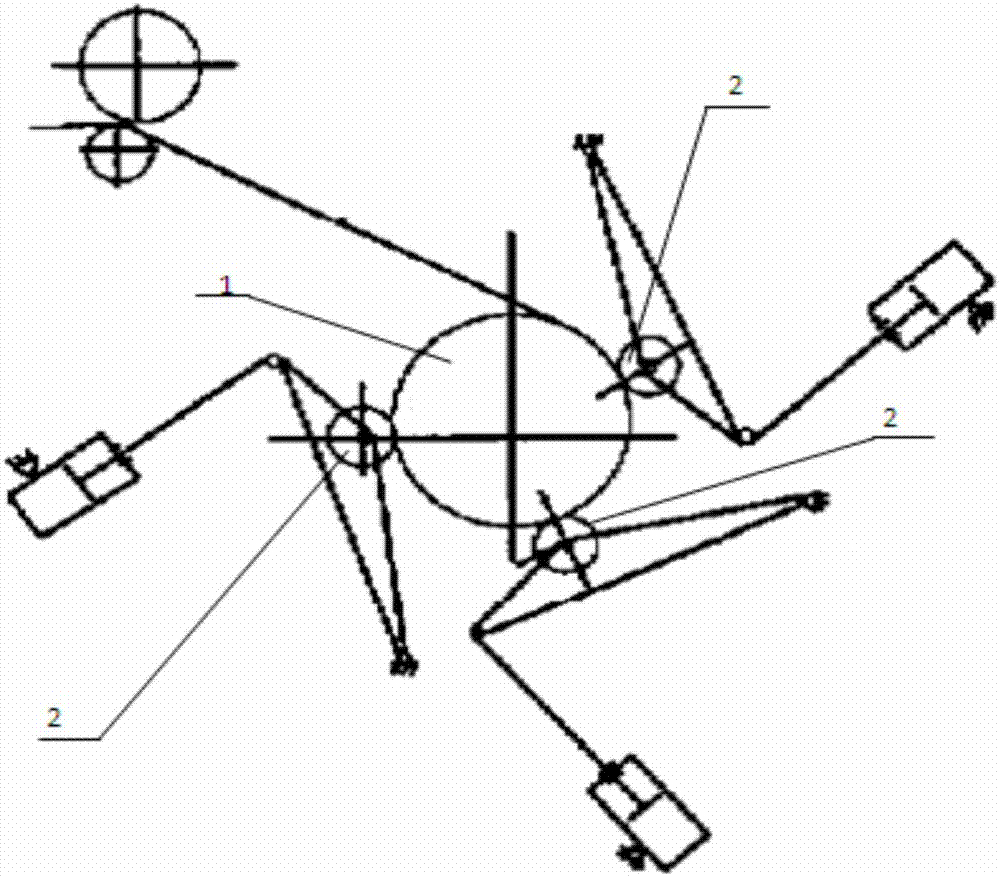

[0027] Referring to the accompanying drawings of the description, a method for automatically calibrating and verifying the accuracy of the coiling roll roll gap of the coiler according to the present invention will be described in detail below.

[0028] As shown in the figure, a method for automatic calibration and accuracy verification of the roll gap of a coiler auxiliary roll according to the present invention, the specific calibration steps are as follows:

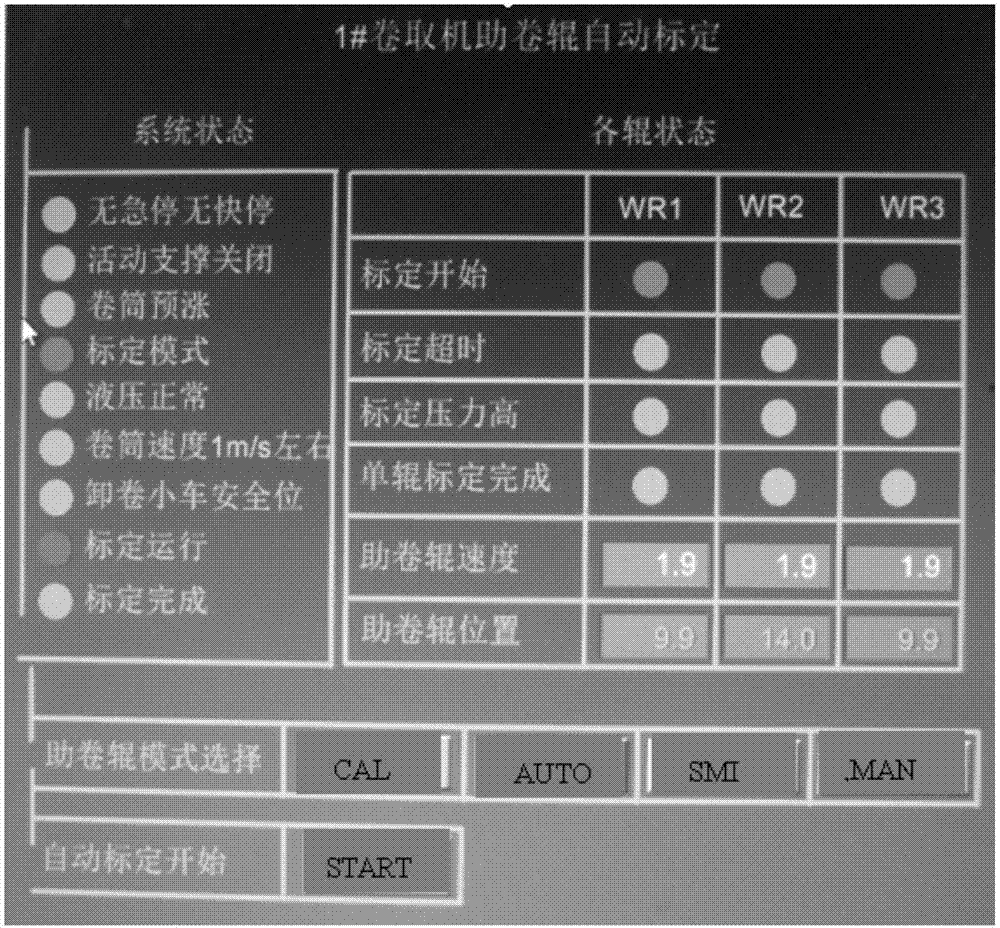

[0029] 1) On the OPU operation panel, select the roll assist roll 2 to be calibrated (3 roll aid rolls can be selected at the same time, or a roll assist roll can be selected individually according to needs); on the OPU operation panel, select a roll assist roll to be calibrated , or select the three roll rolls that need to be calibrated, and switch according to the calibration requirements.

[0030] 2) Open the calibration screen of the winding aid roll, and switch the working mode of the winding aid roll of the coile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com