The Method of Controlling the Width of Mixed Slab

A width control and slab technology, which is applied in rolling mill control devices, manufacturing tools, metal rolling, etc., can solve problems affecting product quality, width control fluctuations, and difficulty in width control, so as to solve the problem of width control and reduce abnormal losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

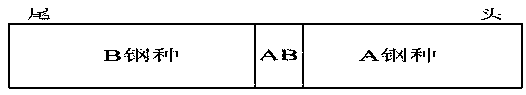

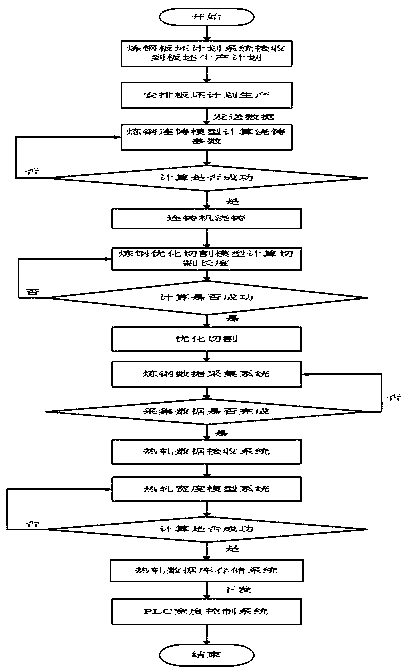

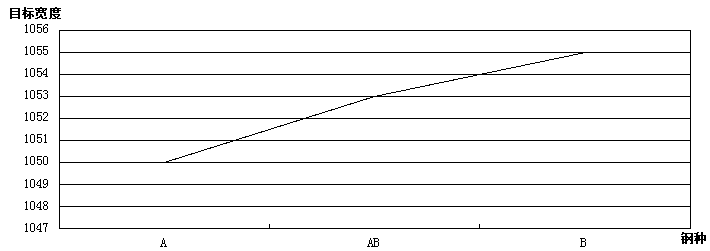

[0061] After cutting through the continuous casting optimized cutting system, the steelmaking continuous casting system accurately records the length of the A steel grade section in the slab as 3 meters, the length of the AB section is 2 meters, and the length of the B steel grade section is 4 meters, and the corresponding The data is saved in the continuous casting database system. The data is the same as the material information of the main chemical composition of steel grade A (AP1360C1), the material information of the main chemical composition of steel grade B (AP1560C1) and the main chemical composition of steel grade AB (AP1460C1) The material information is sent to the hot rolling data receiving system, and the hot rolling data receiving system saves the data in the hot rolling database system and sends them to the width model calculation. The width model calculates the target width according to formula 2 and saves it to Array_valueX array. Corresponding parameters of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com