Double-curvature plate roller bending forming device

A double curvature and roll bending technology, applied in the field of mechanical engineering, can solve problems such as complex structure and easy loss of stability, and achieve the effect of improving stability, high bearing capacity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0034] The invention provides a double-curvature plate roll forming device.

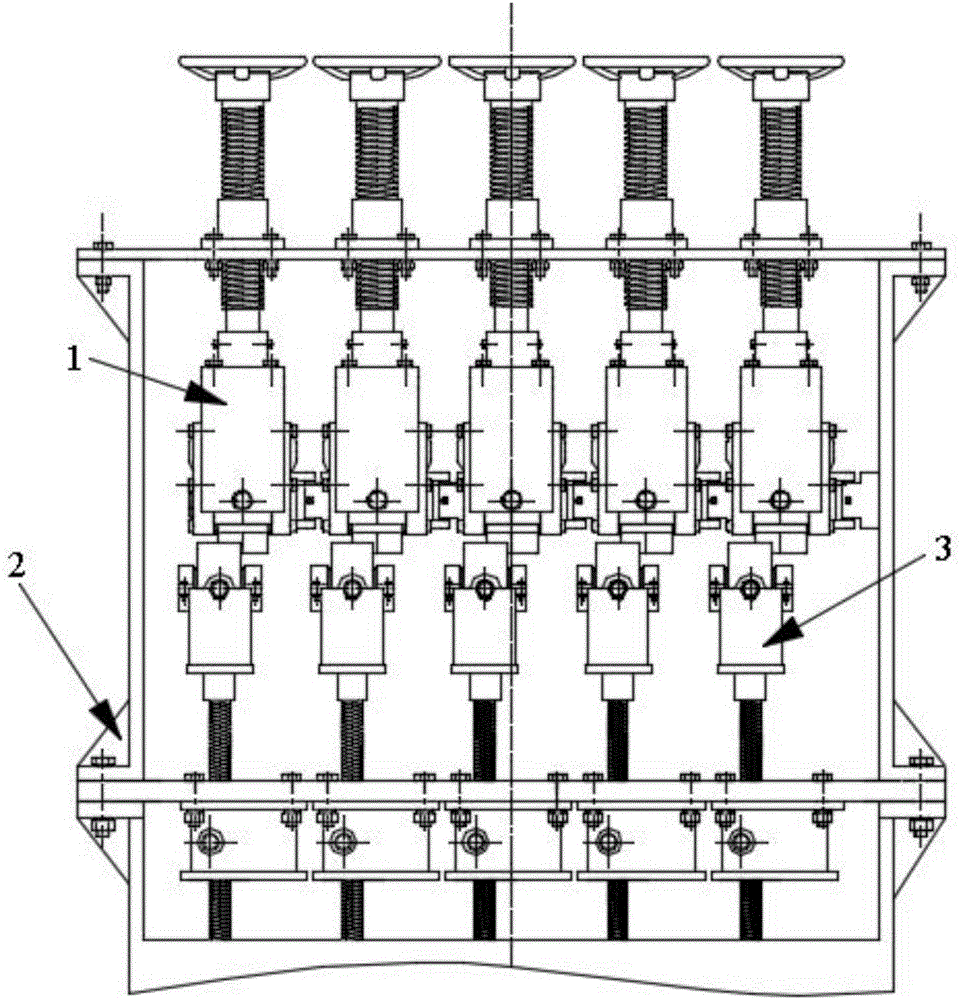

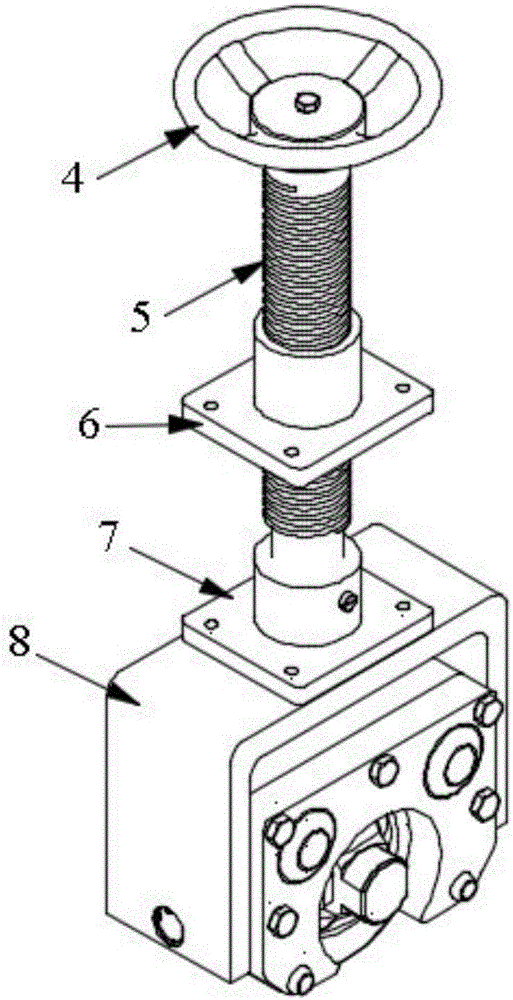

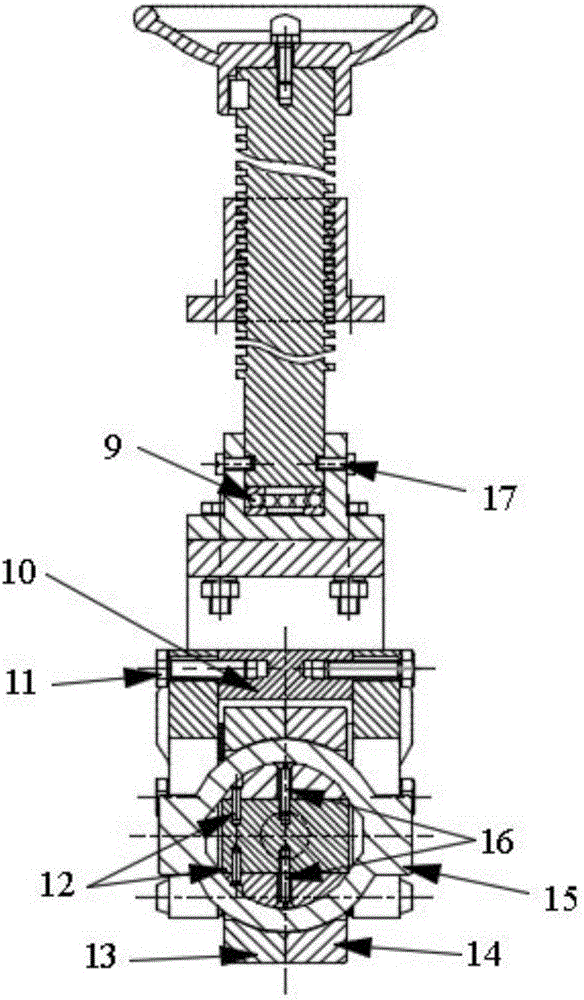

[0035] Such as figure 1The above is a schematic diagram of the core part of the double-curvature plate roll forming device. A row of five rolling units 1 is arranged on the upper part, and two rows of five driven roller-type lower working roller units 3 are arranged in parallel on the lower part. According to the shape of the three-dimensional curved surface to be processed, first, adjust the reduction amount of each reduction mechanism by computer or manually, and adjust the height of the work rolls, so that the work rolls are arranged into the required curve. The effect is that the upper row of rolling unit 1 presses down the plate, and under the joint action of the two row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com