Vehicle starter stator shell automatic punching line

A technology for starting and setting the stator of an automobile, which is applied in positioning devices, feeding devices, storage devices, etc., can solve the problems of affecting product quality, poor machining accuracy, and high labor intensity, and achieves reduction of human resources and labor intensity, and production. cost, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

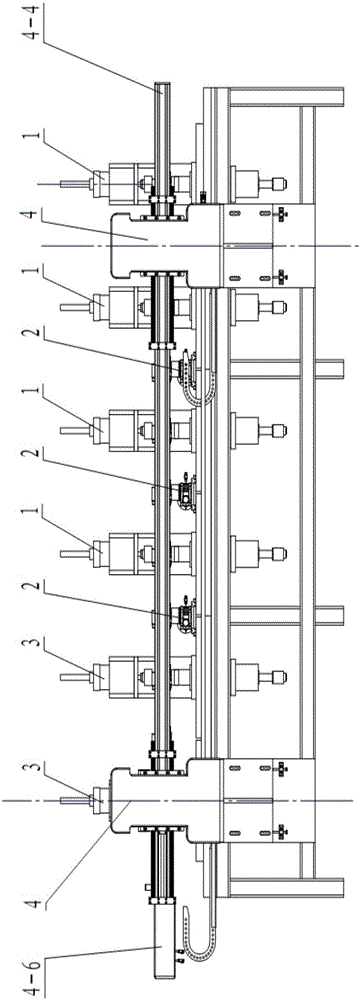

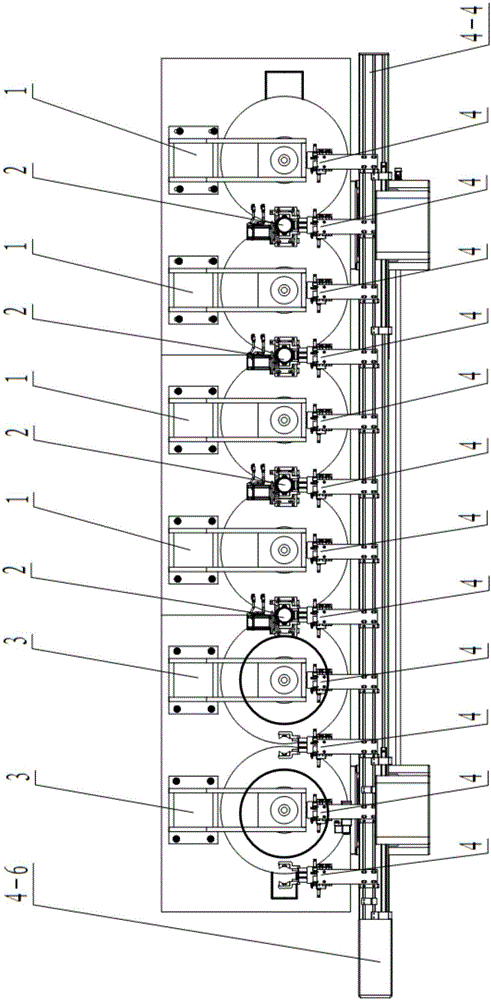

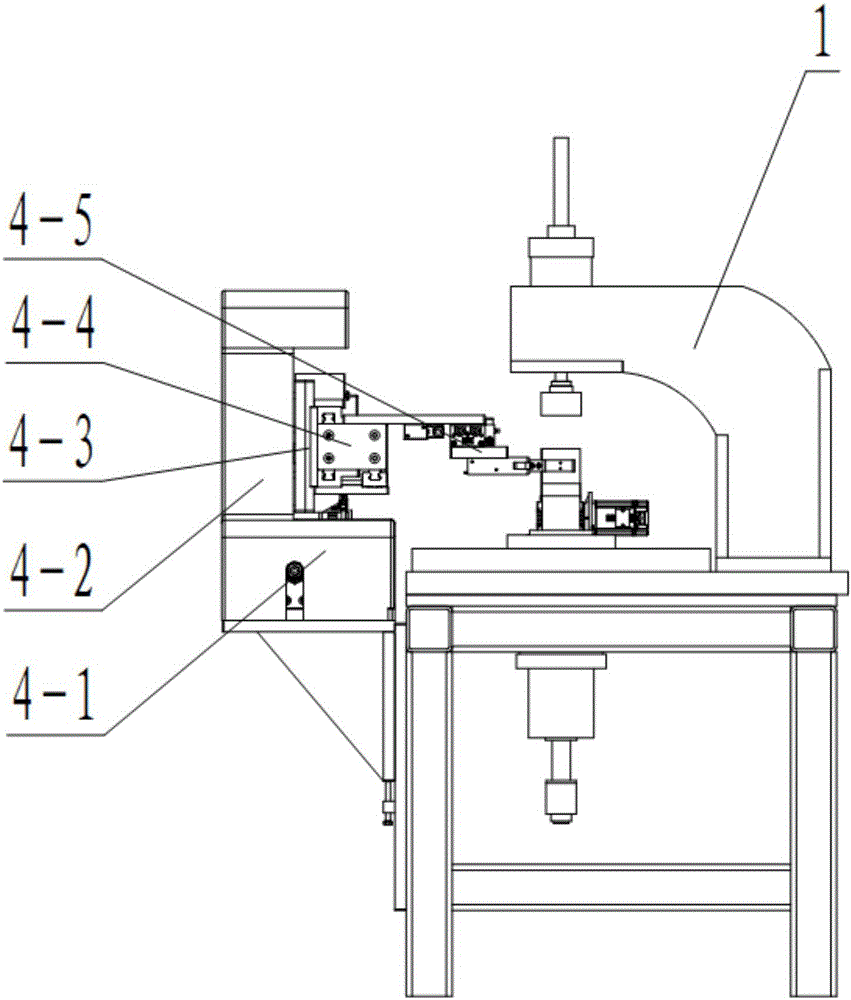

[0062] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a control system 5, 4 hydraulic punches 1 and 2 brush holder bump punching devices 3, the 4 hydraulic punches 1 are connected into one body, and each hydraulic punch 1 is equipped with a casing positioning device 2 , under the control of the control system 5, from right to left, one U-shaped wire lead-out hole punching on the lower end surface, one round drain valve installation hole punching, one rectangular groove punching on the upper end surface and one rectangular groove on the lower end surface are respectively carried out. Groove punching, two brush holder bump punching devices 3 are connected into one body, under the control of the control system 5, one set is used for punching two brush holder positioning bumps, and the other is used for six brush holder limit bumps Point punching, in front of each hydraulic punch 1 and each brush holder bump punching device 3, there are 2 sets of pneumatic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com