A method of welding titanium-aluminum dissimilar metals using femtosecond laser

A femtosecond laser and dissimilar metal technology, applied in the welding of aluminum metal materials, the femtosecond laser passes through the transparent material to the titanium field, which can solve the problems of poor weldability of aluminum and titanium dissimilar metals, and the joint strength cannot meet the requirements, and achieves fast heating speed. , Strengthen the strength, avoid the effect of being oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

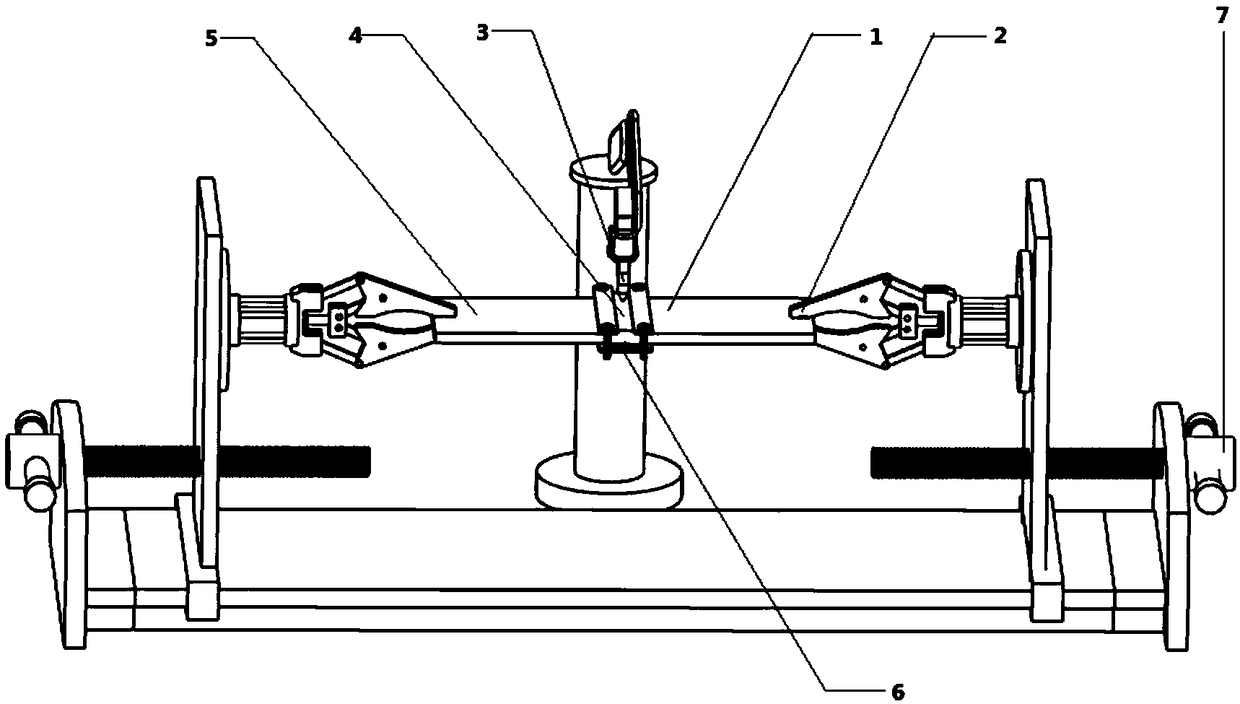

[0025] as attached figure 1 As shown, both the titanium plate 1 and the aluminum plate 5 are processed into a size of 3 mm thick and 150 mm×150 mm, and then the surface is cleaned and polished with absolute ethanol. The surfaces of the surfaces to be joined of the titanium plate 1 and the aluminum plate 5 were finished so that the surface roughness Ra was 0.05 μm. Then align the titanium plate 1 and the aluminum plate 5 to be connected with the first clamp 2 and fix them. Then rotate the screw handle 7 to apply pressure to the connection surface to ensure that there is no gap in the connection surface. The glass plate 4 is processed into a cover plate, and the pretreatment is carried out, and the surface is finished, and the surface roughness Ra is 0.04 μm. Then the second clamp 6 is used to fix it around the connection surface around the titanium plate 1 and the aluminum plate 5 to ensure that the connection surface is sealed in the glass plate 4 . Calibrate the focus of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com