Automatic complex special-shaped workpiece welding track generation system and method

An automatic welding and trajectory generation technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of thin-walled workpiece contour deformation, positioning error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

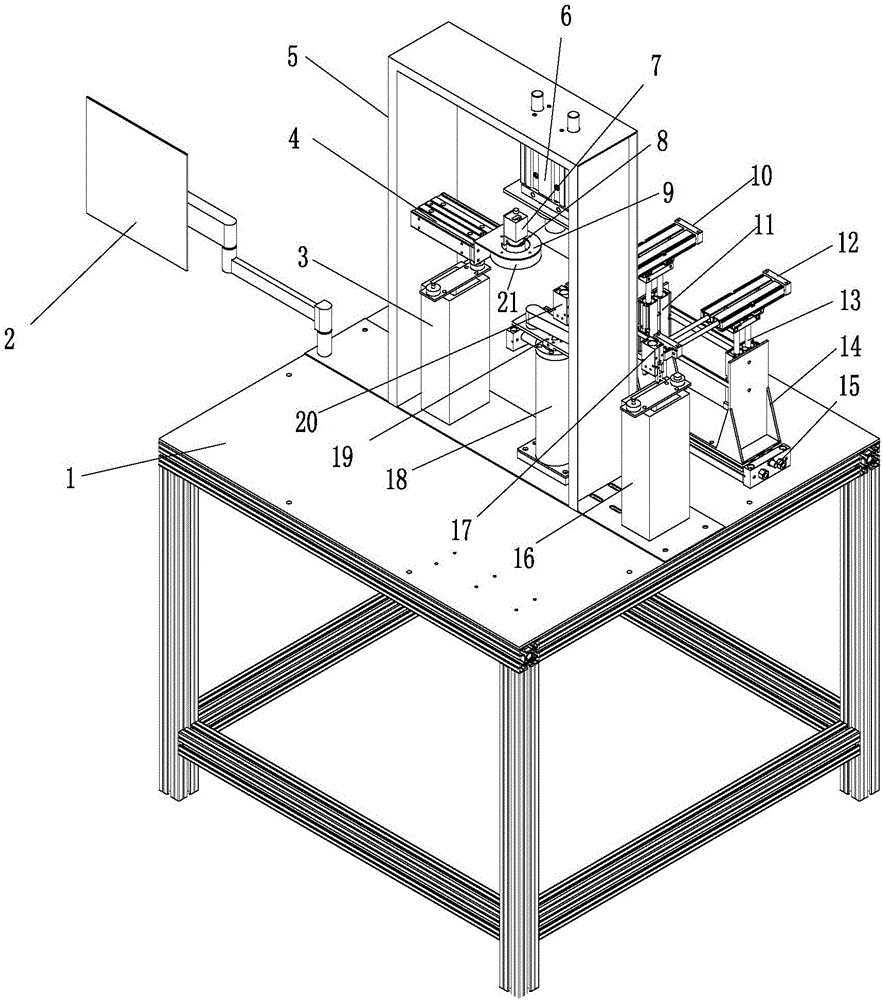

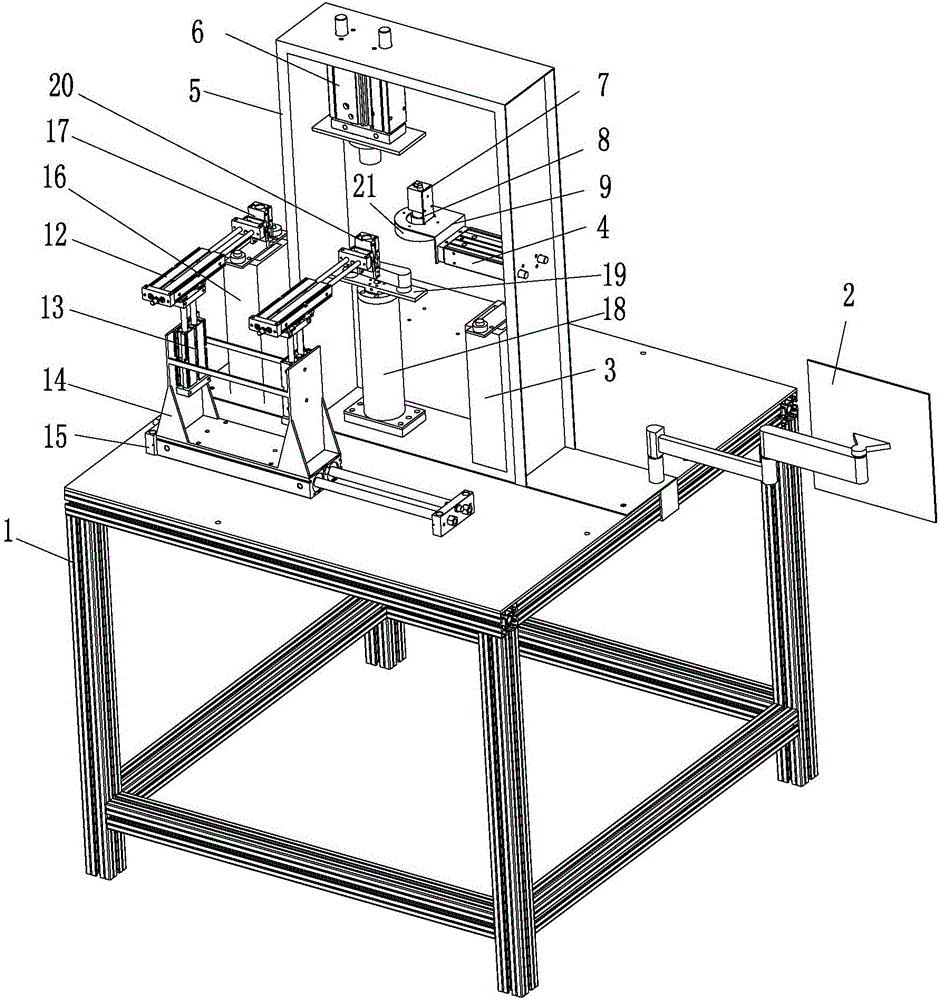

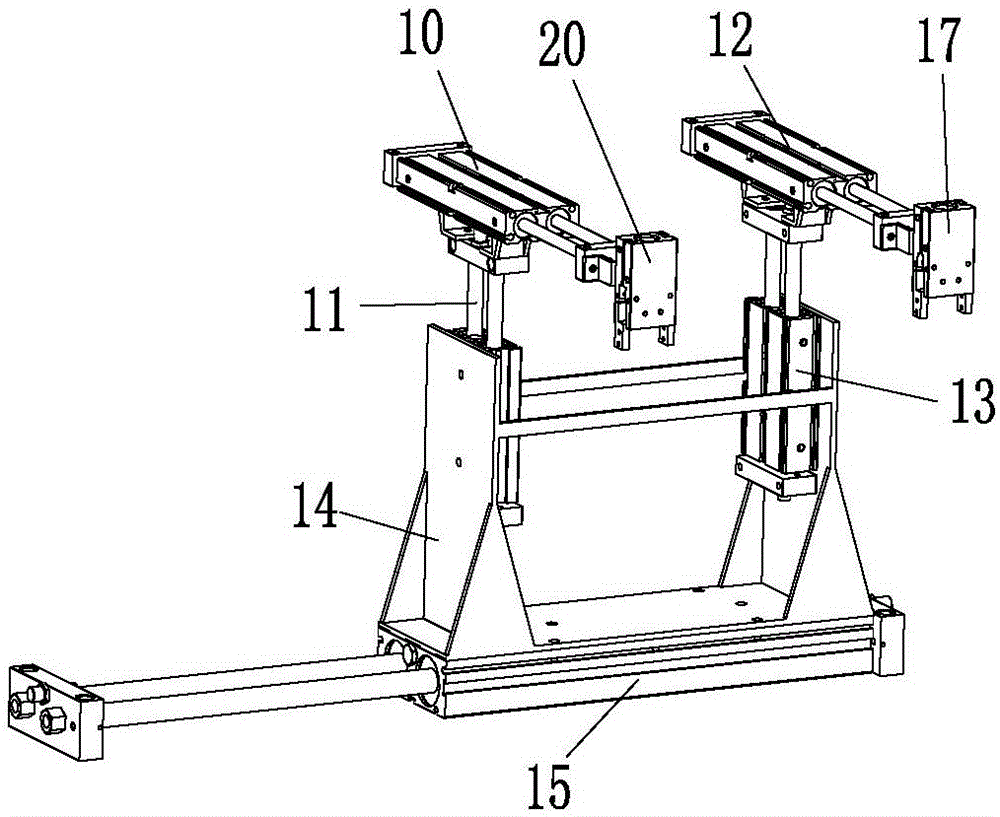

[0066] like Figure 1 to Figure 3 As shown in the figure, an automatic welding trajectory generation system for complex special-shaped workpieces includes a workbench, a workpiece support rotary table for fixing workpieces, a workpiece clamping system for three-axis movement of workpieces, a machine vision measurement system, a touch screen, and a motion Control System,

[0067] The workpiece support turntable and the workpiece clamping system are arranged on the workbench, and the workpiece support turntable includes a rotary servo motor 18 vertically arranged on the workbench 1, a shaft connected to the output shaft of the rotary servo motor 18 Rotating fixture 19; the touch display screen is connected with the motion control system circuit, and fixed on one side of the workbench through the installation arm, and the machine vision measurement system is fixed on the workbench through the machine vision measurement system support platform, and is connected to the workbench th...

Embodiment 2

[0074] A method for automatically generating welding trajectories for complex and special-shaped workpieces based on the system, comprising steps:

[0075] (1) The camera component acquires the image of the workpiece, and preprocesses the acquired image to extract the outline to obtain data points;

[0076] (2) Perform NURBS fitting on the obtained data points to obtain the welding trajectory;

[0077] (3) The motion control system sends corresponding motion pulses to each servo motor in combination with the generated welding trajectory, and drives the welding manipulator to perform corresponding contour welding.

[0078] Specifically, described step (1) specifically includes:

[0079] (11) Obtain the image of the workpiece, and use Halcon to separate, corrode, and extract the skeleton of the image;

[0080] (12) Eliminate the image noise area irrelevant to the welding track;

[0081] (13) Obtain the image outline under the sub-pixel progress;

[0082] (14) Obtain the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com