A method and device for preparing black silicon

A technology of black silicon and silicon materials, applied in the field of semiconductor optoelectronic materials, can solve the problems of difficult engineering application, difficult mass production, affecting the processing efficiency of black silicon, etc., and achieve the effect of good absorption rate and short pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0059] As an embodiment, the method for preparing black silicon includes the following steps:

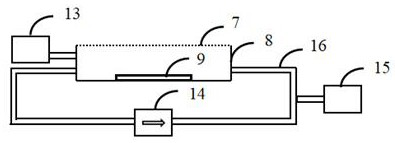

[0060] Step 1, place the silicon material 9 in a sealed gas chamber 8, use the vacuum pump 13 to extract the air in the sealed gas chamber 8 through the vacuum pumping port 11, close the vacuum pumping port 11 and the vacuum pump 13 after the pumping is completed, and then open Gas source 15 access gas.

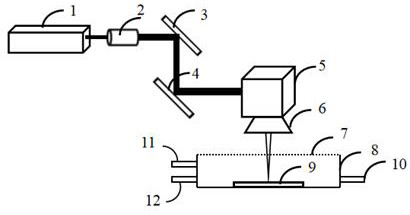

[0061] Step 2, the laser beam emitted by the ultrafast laser 1 passes through the beam expander collimating mirror 2, the first reflector 3 and the second reflector 4, enters the high-speed galvanometer 5, and then focuses through the field mirror 6, as figure 1 As shown, wherein, the wavelength of the ultrafast laser 1 is 1030nm or 1064nm, and the pulse width is less than 12ps. The focused beam passes through the laser light opening 7 at the top of the airtight gas chamber 8 and focuses on the surface of the silicon material 9 or above the silicon material 9 , which is not lim...

Embodiment 1

[0066] This embodiment provides a method for preparing black silicon, using an ultrafast infrared laser with a wavelength of 1030nm and a pulse width of 480fs to The silicon wafer area is etched, the laser repetition frequency is 100kHz, and the diameter of the active spot is adjusted to , the spot energy density is , the horizontal and vertical overlapping ratios of the facula are set to 93%. Processed samples such as image 3 As shown, it can be seen that the whole etched area has a high degree of blackening, which is in obvious contrast with the surrounding original materials. Observing the microscopic morphology of the etched area through a confocal microscope, it was found that the entire area is composed of a large number of pointed cone-shaped microstructures, which are clear and dense as a whole, such as Figure 4 As shown, the height measurement shows that the heights of these conical microstructures are about. Finally, the absorbance of the sample to the 400...

Embodiment 2

[0068] This embodiment provides a method for preparing black silicon, using an ultrafast infrared laser with a wavelength of 1064nm and a pulse width of 1ps to The silicon wafer area is etched, the laser repetition frequency is 175kHz, and the diameter of the active spot is adjusted to , the spot energy density is , the horizontal and vertical overlapping ratios of the facula are set to 95%. Processed samples such as Image 6 As shown, it can be seen that the whole etched area has a high degree of blackening, which is in obvious contrast with the surrounding original materials. Observing the microscopic morphology of the etched area through a confocal microscope, it was found that the entire area is composed of a large number of pointed cone-shaped microstructures, which are clear and dense as a whole, such as Figure 7 As shown, the height measurement shows that the heights of these conical microstructures are about. Finally, the absorbance of the sample to the 400nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com