Automatic cleaning drilling and milling complex machine tool

A compound machine tool, automatic cleaning technology, used in metal processing machinery parts, other manufacturing equipment/tools, maintenance and safety accessories, etc., can solve difficult to ensure high precision drilling and milling, positioning device and mobile device matching accuracy requirements are too high. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

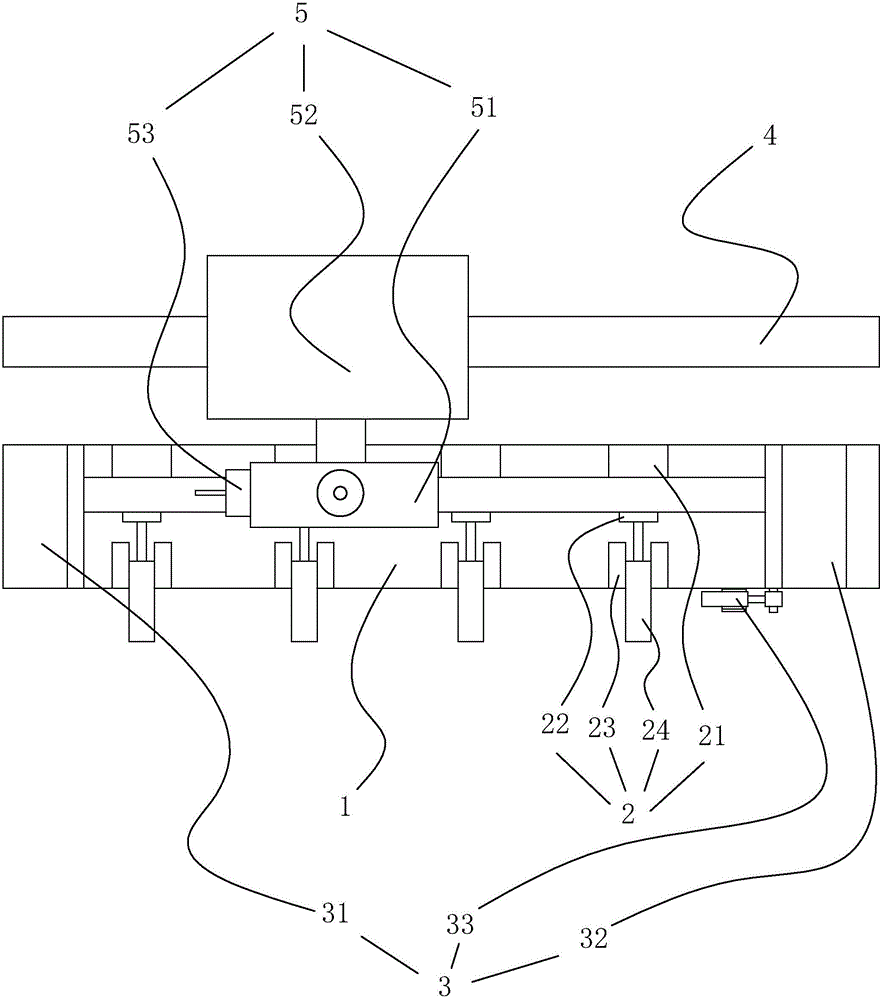

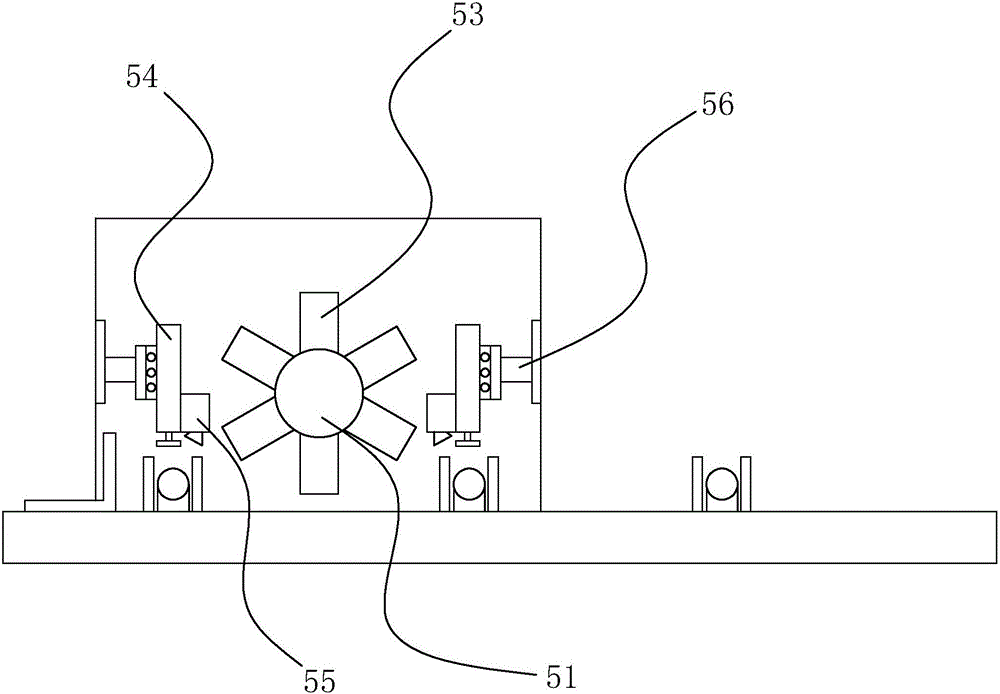

[0011] Such as Figure 1-Figure 2 As shown, a self-cleaning drilling and milling compound machine tool includes a rectangular processing table 1, a clamping mechanism 2 and a gear mechanism 3 arranged on the processing table 1, a guide rail 4 parallel to the long side of the processing table 1, The slidable drilling and milling assembly 5 arranged on the guide rail 4; the pipe to be processed is placed on the processing table 1 parallel to the long side of the processing table 1, and the clamping mechanism 2 includes a fixed block 21 arranged on the processing table 1, The top block 22 and the base 23, the base 23 is provided with the first gas top 24 that pushes the top block 22 to move toward and away from the fixed block 21; The moving plate 32 on the other side of the pipe and the second air cap 33 that pushes the moving plate 32 to move toward and away from the fixed plate 31; The cutterhead 51 is a positioning mechanism 52 that moves horizontally, vertically and vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com