Working method of automatic clamping device for large plate

A technology of clamping device and working method, which is applied in the field of plate processing, can solve problems such as potential safety hazards, high labor intensity, and unstable quality, and achieve the effects of improving efficiency, improving quality, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

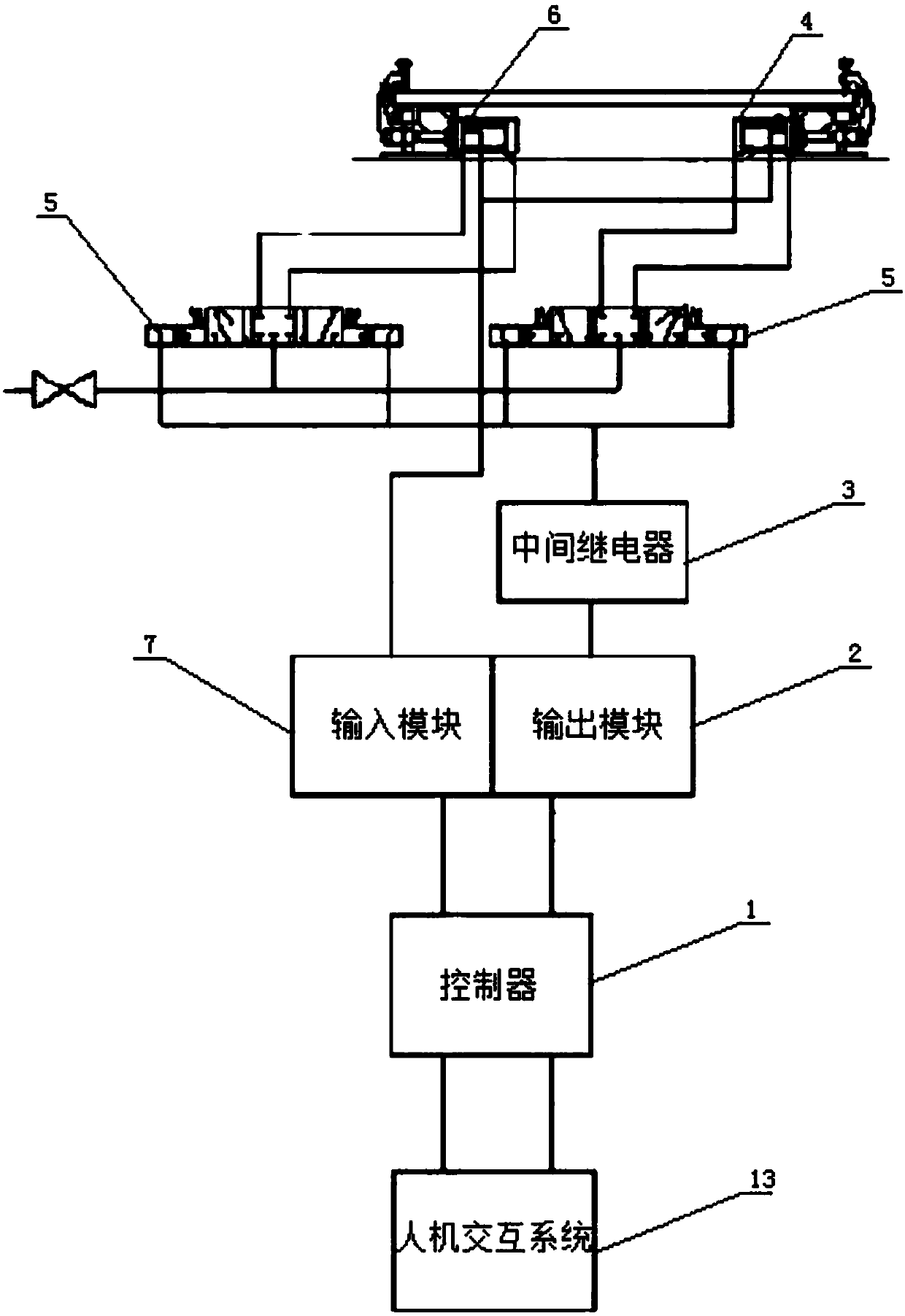

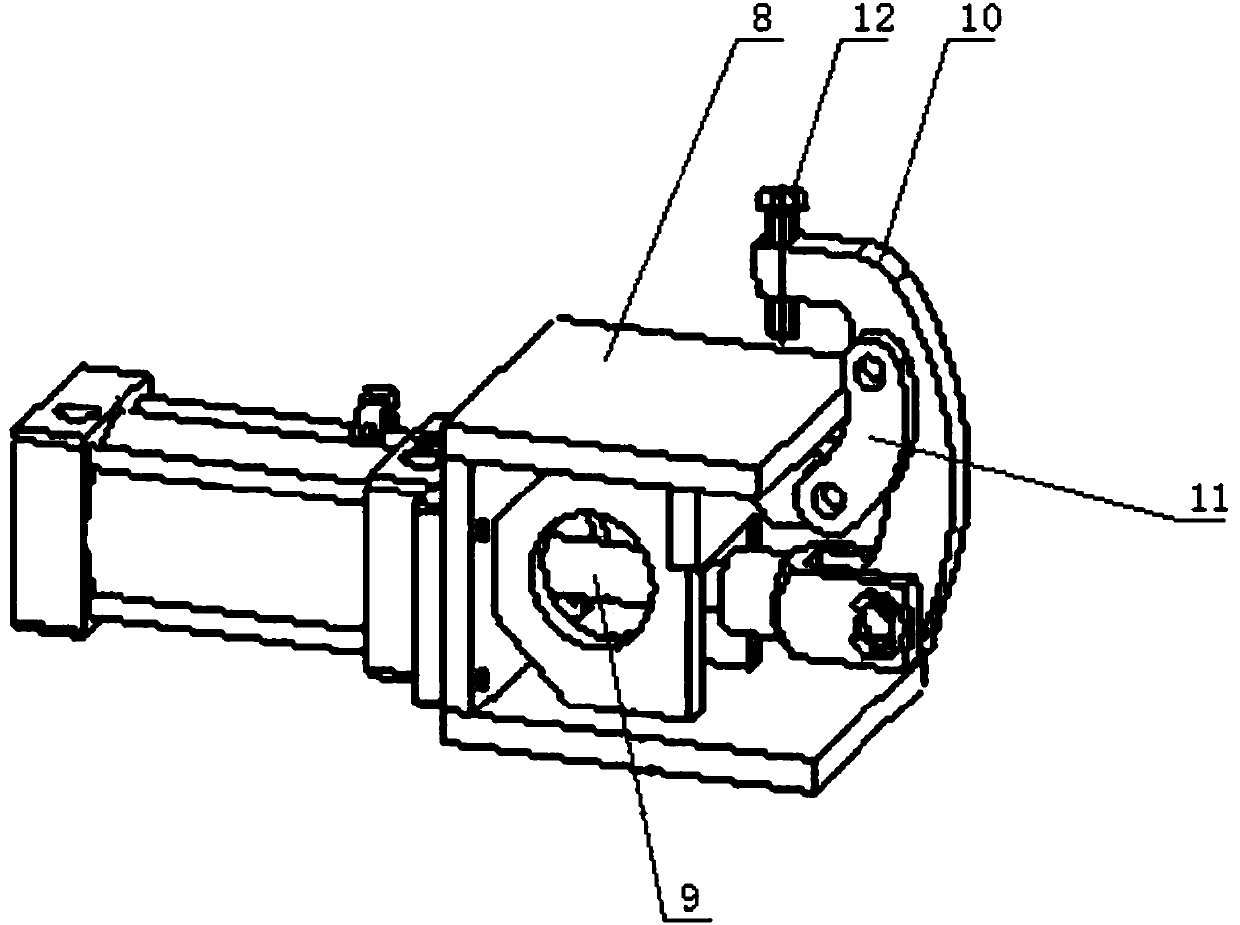

[0029] Such as figure 1 and figure 2 As shown, the large plate automatic clamping device includes a controller 1 and multiple clamping mechanisms; the signal output terminal of the controller 1 is electrically connected to the output module 2, and the signal output terminal of the output module 2 is connected with the signal of each clamping mechanism respectively. The input end is electrically connected; the clamping mechanism includes an intermediate relay 3 and two locking structures for locking the plate; the locking structure is connected with a cylinder 4 that controls its work; the cylinder 4 is connected with an electromagnetic reversing valve that controls its work 5. The two electromagnetic reversing valves 5 are electrically connected to the intermediate relay 3; the signal output terminal of the output module 2 is electrically connected to the signal input end of the intermediate relay 3; the electromagnetic reversing valve 5 is connected to an air source; the con...

Embodiment 2

[0033] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that the clamping mechanism also includes two signal switches 6 for monitoring the action of the cylinder 4; the signal input end of the controller 1 is electrically connected with an input module 7, and the input module 7 The signal input end of each signal switch 6 is electrically connected with the signal output end of each signal switch 6; the cylinder 4 is monitored by the signal switch 6, and the cutter and the indenter 12 are placed to collide, causing damage to the cutter and the indenter 12.

[0034] The working method of the large plate automatic clamping device comprises the following steps:

[0035] 1.1 Place the locking structure according to the shape of the plate and fix it on the workbench; move the tool to the top of the indenter, input and store the current coordinate value of the indenter in the controller through the human-computer interaction system, and set thres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com