Pipe fitting station switching mechanism

A technology for switching mechanisms and pipe fittings, which is applied in metal processing, manufacturing tools, and other manufacturing equipment/tools, and can solve problems such as increasing labor costs and reducing the degree of automation of pipe fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

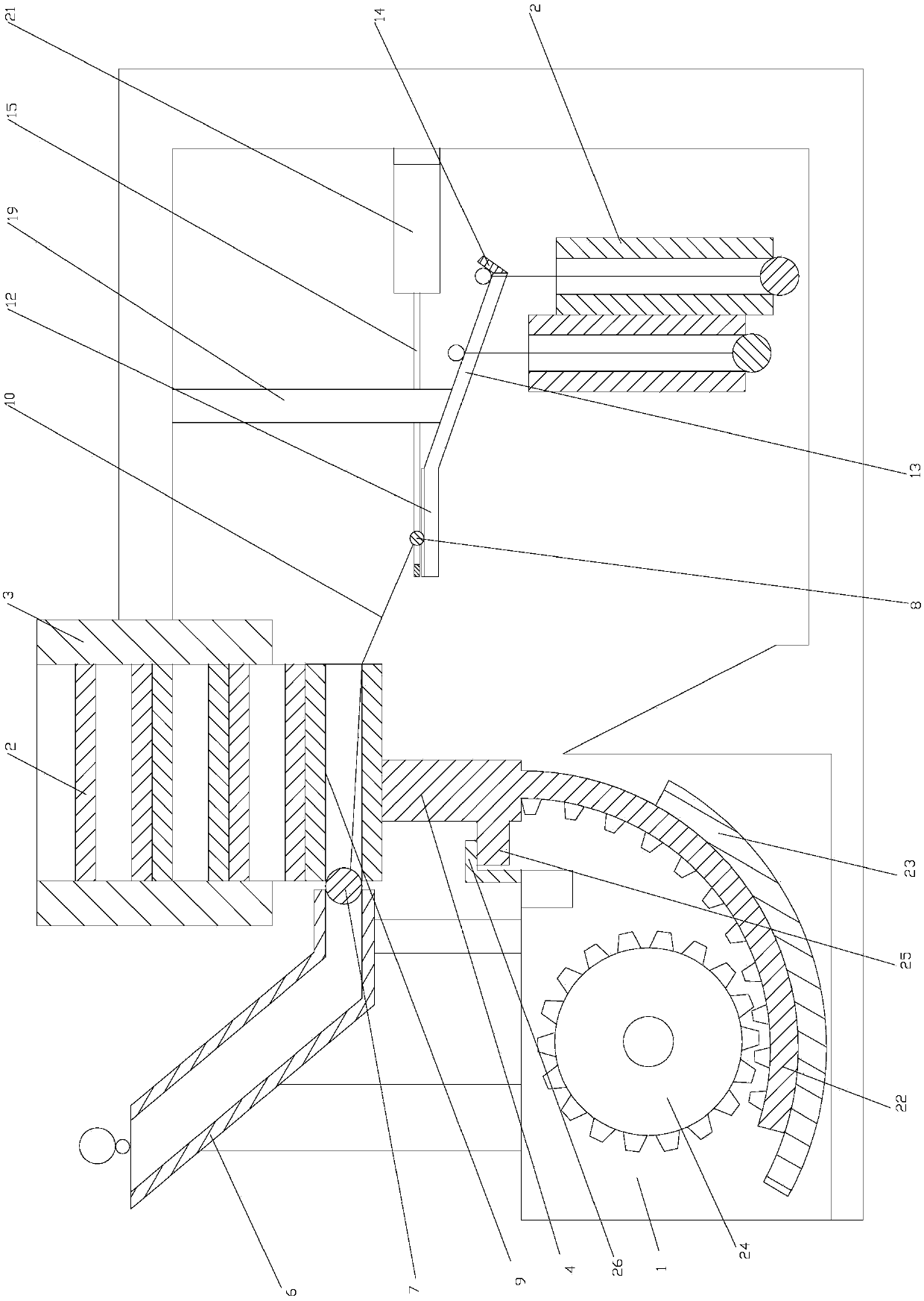

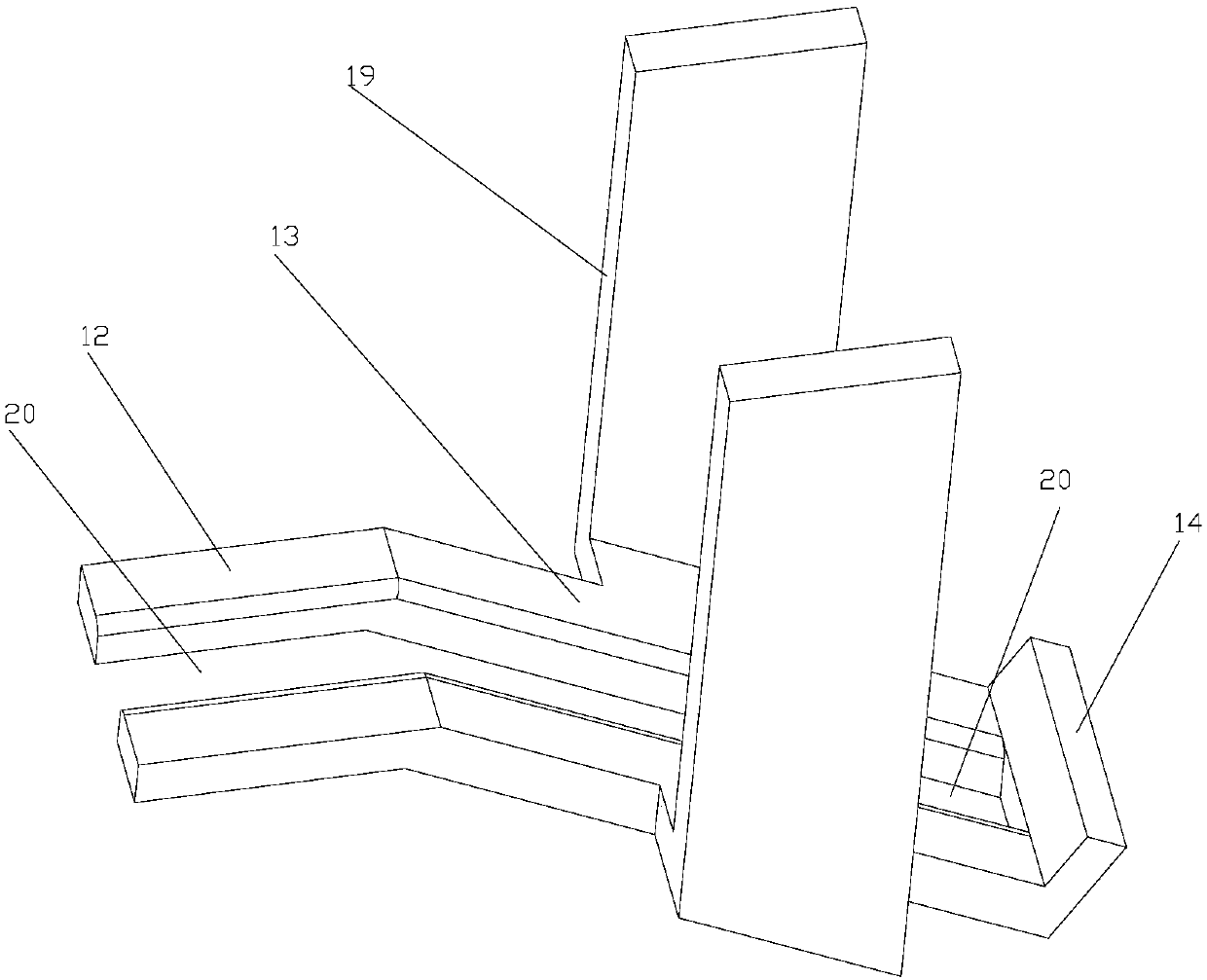

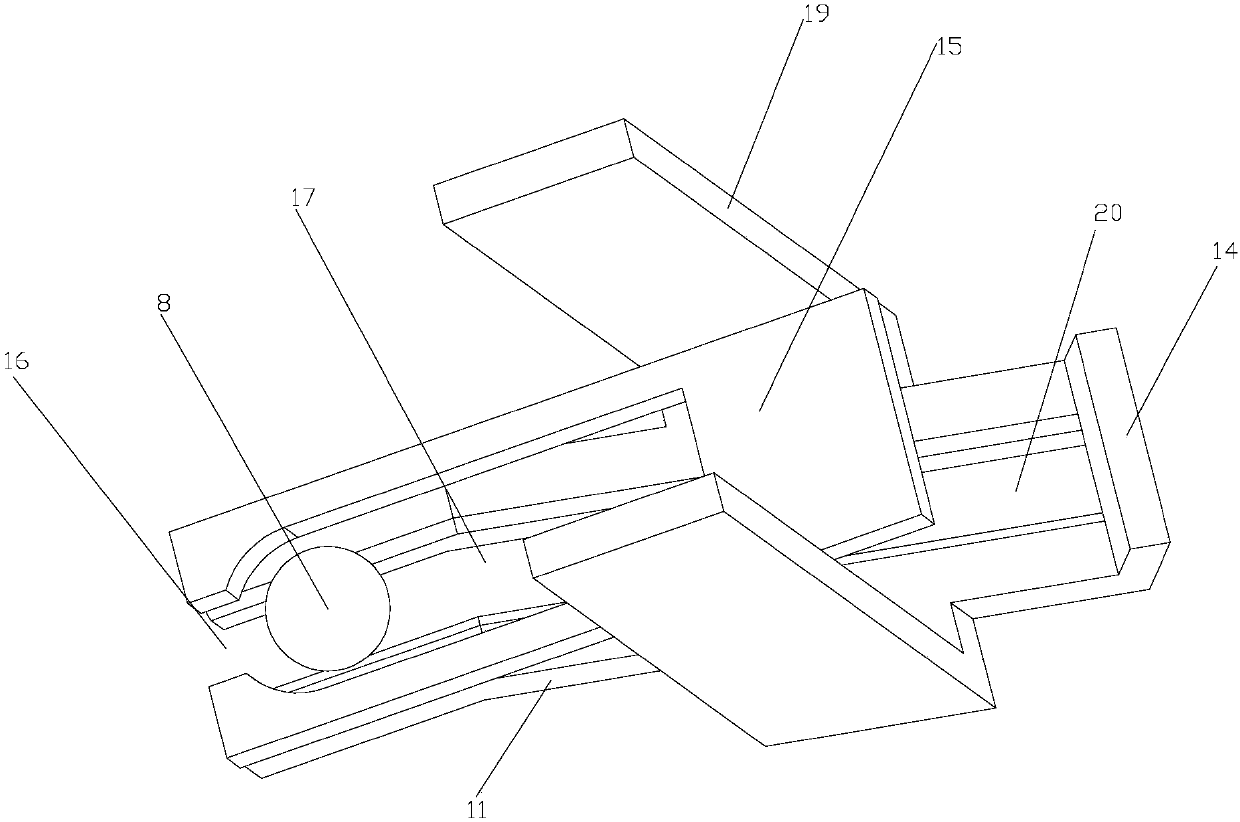

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] Working principle of the present invention:

[0020] First, the pipe fittings that have just milled the end face are placed in the barrel, the pipe fittings are in a horizontal state, the lowest pipe fitting is against the support block, and the lowest pipe fitting is separated from the lower port of the barrel, as shown figure 1 As shown; the operator puts a group of steel ball pulling mechanisms into the inclined tube, and the small steel ball is located below the large steel ball, that is, to ensure that the small steel ball enters the inclined tube first; the small steel ball and the large steel ball roll along the inner wall of the inclined tube, and the small steel ball takes the lead. Through the through hole on the pipe fitting, after the small steel ball leaves the through hole of the pipe fitting, it makes a parabolic motion an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com