Novel plane grinding and polishing machine

A polishing machine and plane technology, applied in the direction of grinding/polishing equipment, grinding machines, abrasive belt grinders, etc., can solve the problems of high operating proficiency requirements for employees, difficulty in maintaining consistent polishing texture, and difficulty in mastering flatness, etc., to achieve smooth texture Good consistency, convenient and fast assembly, easy clamping and placing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

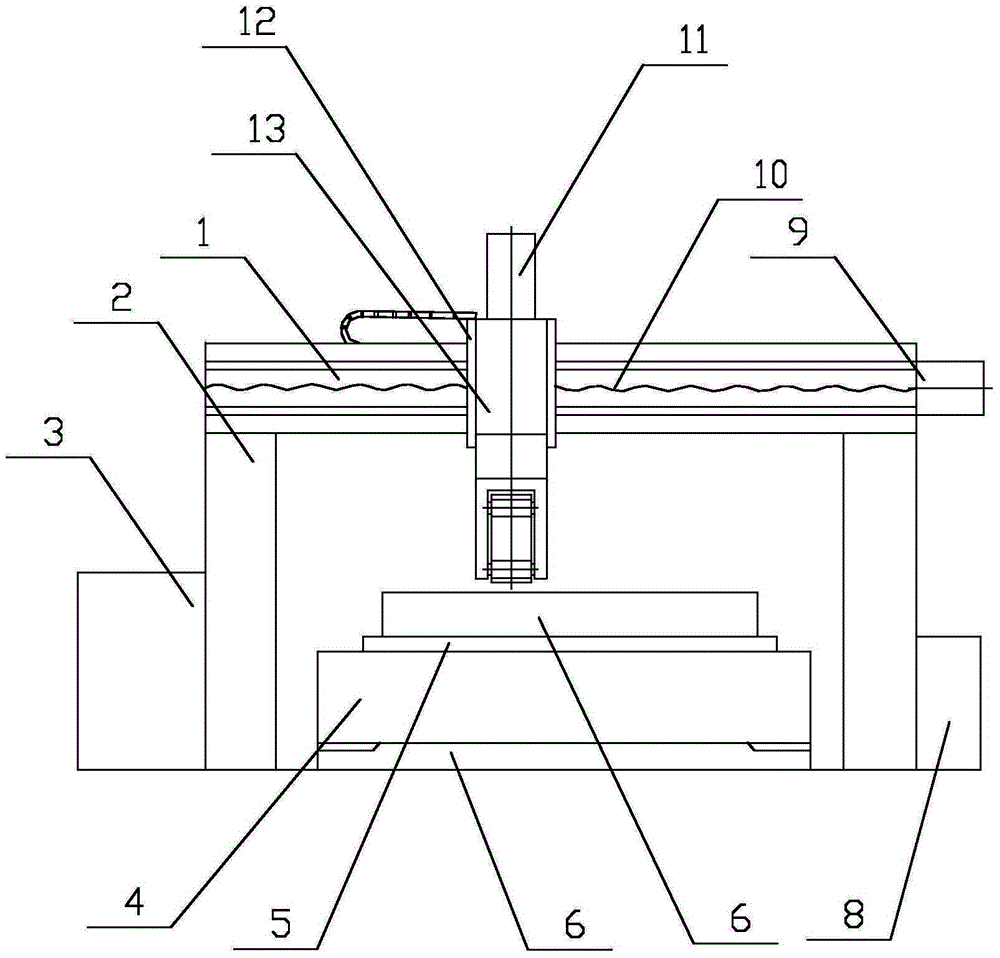

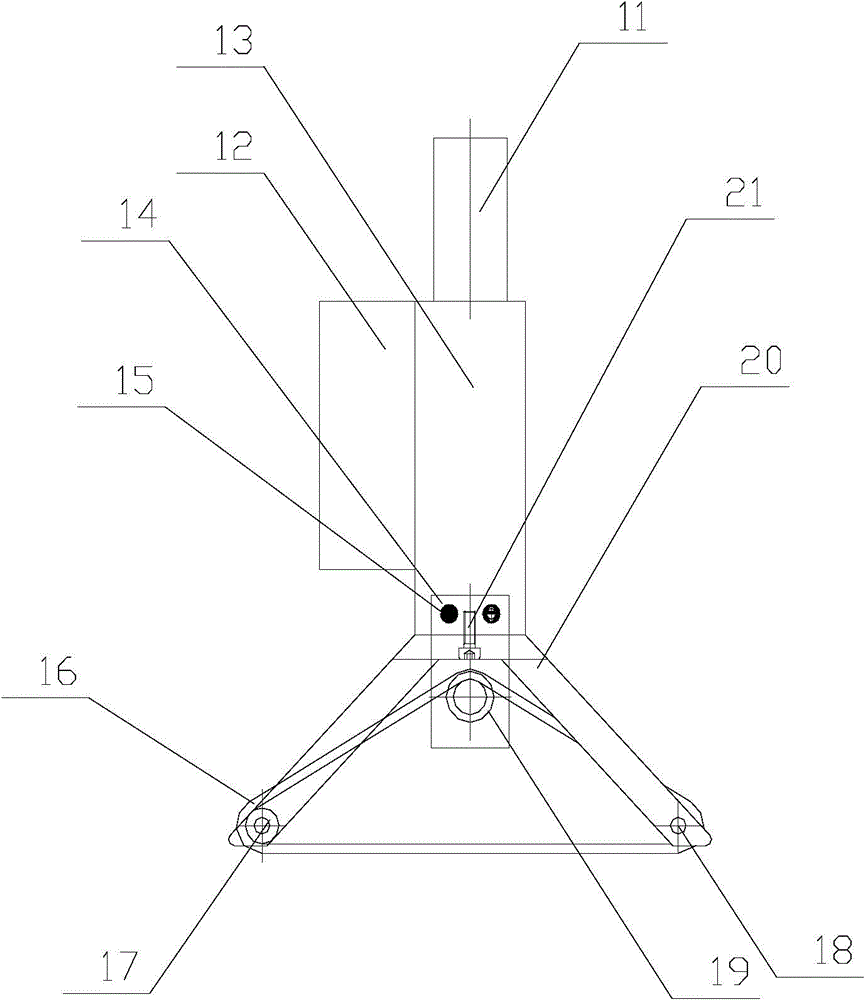

[0018] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: it includes a beam 1, a column 2, a control system 3, a workbench 4, a magnetic chuck 5, a guide rail 6, a workpiece 7, a polishing machine controller 8, a first motor 9, a wire Rod 10, second motor 11, lateral moving device 12 and lifting mechanism 13, crossbeam 1 is fixed on the column 2, two columns 2 are respectively located on both sides of the beam 1, control system 3 is located under the left side of the left column 2, guide rail 6 is located Between the two columns 2, the workbench 4 is movably connected to the guide rail 6, the workbench 4 is provided with a magnetic chuck 5, the workpiece 7 is fixed on the magnetic chuck 5, the polishing machine controller 8 is located under the right side of the right column 2, and the first motor 9 is fixed on the right side of the beam 1, the left side of the first motor 9 is connected with a screw 10, the screw 10 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com