Ultrasonically-assisted grinding wheel grinding grain arrangement strategy and grinding grain thickness cutting model establishment method

An ultrasonic-assisted grinding wheel grinding technology, which is applied in the direction of bonded grinding wheels, abrasive materials, instruments, etc., can solve the problems of redundant abrasive grains, obvious differences, and the lack of a single abrasive grain cutting thickness model, etc., to achieve easy implementation and versatility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

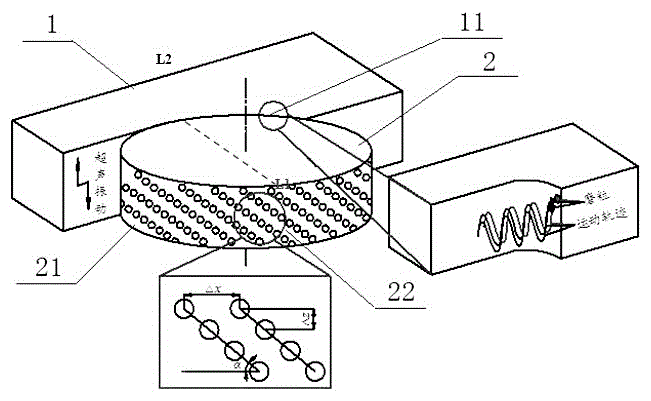

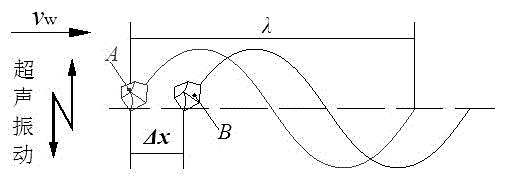

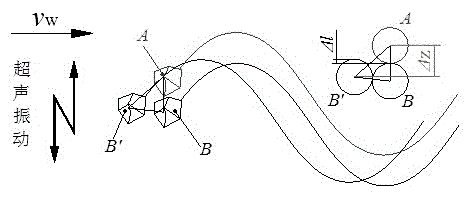

[0055] The working parts of the ultrasonic-assisted grinding wheel include the workpiece 1 to be ground and the grinding wheel 2. The workpiece 1 has a grinding arc area 11, and the side wall of the grinding wheel 2 is a working surface 21. The working surface 21 is in contact with the grinding arc area 11, and the working surface 21 is provided with abrasive grains 22, and the abrasive grains 22 are arranged in an orderly manner on the working surface 21. The control method for the orderly arrangement of the abrasive grains 22 is as follows: sequentially determine the circumferential spacing Δx of the abrasive grains in the working layer, and the abrasive grains Axial spacing Δz, abrasive particle arrangement angle β. The abrasive grain circumferential distance Δx and the abrasive grain axial distance Δz in the working layer are directly related to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com