Spiral type twisting soft-bodied robot module

A robot and screw-type technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of difficult control, single motion form, lack of torsional freedom, etc., to achieve a wide range of applications, efficient driving, and efficient action execution high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

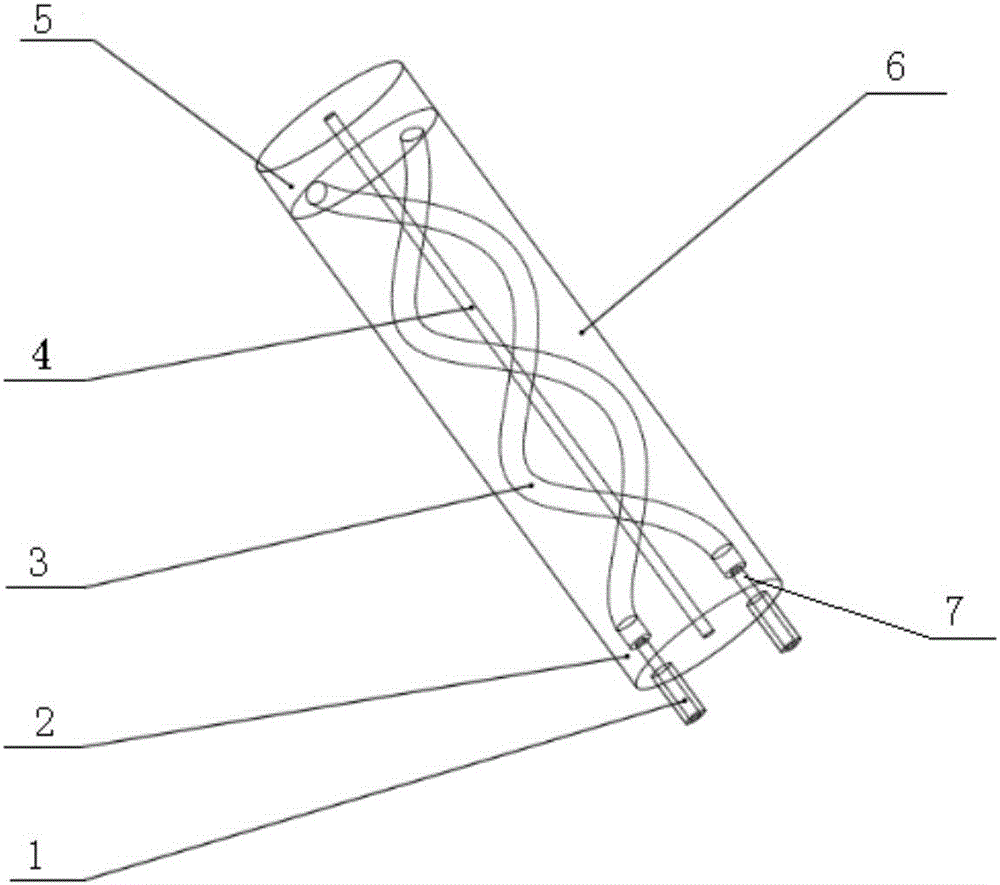

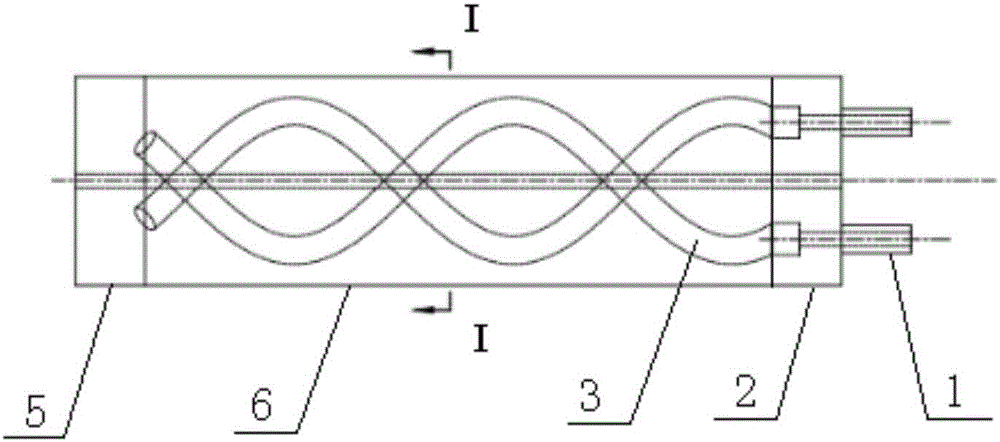

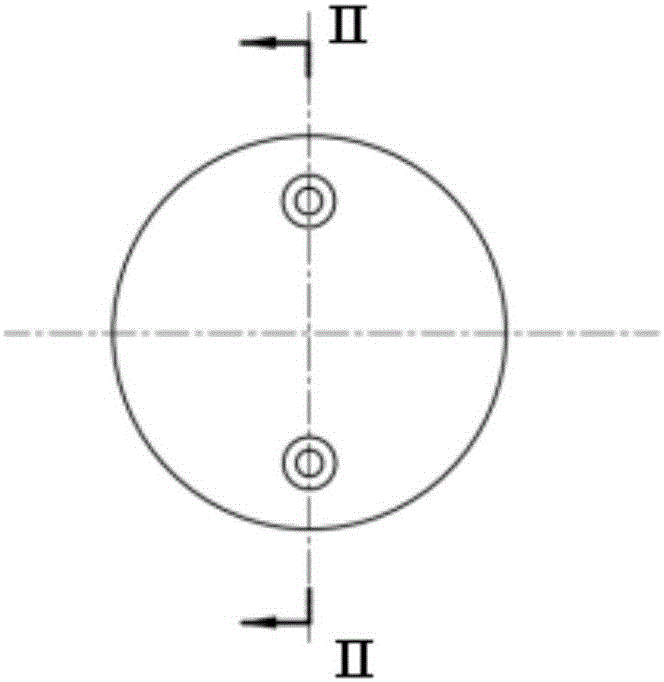

[0022] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Describe this embodiment, this embodiment comprises elastic main body 6, rear plug 2, center restriction strip 4 and front plug 5, and described central restriction strip 4 passes through front plug 5, elastic main body 6 and rear plug 2 successively, and described elastic The main body 6 is processed with a plurality of helical inner cavities 3, and the plurality of helical inner cavities 3 are evenly arranged in the elastic main body 6 with the central restriction strip 4 as the center. The front plug 5 is arranged on the upper end of the elastic main body 6, and the front plug 5 is airtightly connected with the upper opening of each spiral cavity 3, the back plug 2 is arranged at the lower end of the elastic body 6, each spiral cavity 3 corresponds to a connecting pipe 1, and each spiral cavity The lower port of 3 communicates with the corresponding connecting pipe...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment is a further limitation of Embodiment 1. In this embodiment, the elastic body 6 is a cylinder made of elastic silica gel. Axes coincide.

[0028] The elastic body 6 in the present invention is a cylinder made of elastic silicone rubber, specifically a cylinder made of superelastic silicone rubber material.

[0029] The driving technology relied on by the present invention is pneumatic or hydraulic braking deformation, and other fluid elastic bodies capable of actuating deformation can also be used.

[0030] Embodiment 2: This embodiment is a further limitation of Embodiment 1. In this embodiment, the elastic body 6 is a cylinder made of elastic silica gel. Axes coincide.

[0031] The central restricting strip 4 of the present invention is a cylinder, and the central axis of the central restricting strip 4 in the longitudinal direction coincides with the central axis of the elastic body 6 in the longitudinal direction.

specific Embodiment approach 3

[0032] Specific Embodiment 3: This embodiment is a further limitation of Specific Embodiment 2. In this embodiment, both the rear plug 2 and the front plug 5 are cylinders made of elastic silica gel, and the front plug 5 is fixedly connected to the elastic body 6. At the upper end, the rear plug 2 is fixedly connected to the lower end of the elastic body 6, and the elastic body 6, the rear plug 2 and the front plug 5 are coaxially arranged.

[0033] Although the front plug 5 in the present invention is a cylinder made of elastic silica gel, it is harder than the elastic main body 6, which is conducive to the output of torsional angular displacement and torsional force. The hardness of the rear plug 2 is higher than that of the front plug 5, and it is used as the output end of torsional deformation and torsional force. The connecting pipe 1 is made of silica gel, and the central restricting strip 4 is made of cotton thread or other soft ones, which can only rotate but not A str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com