In-situ opening/closing type T-shaped pile mold

An opening and closing, mold technology, applied in the direction of mold, mold fixing device, mold auxiliary parts, etc., can solve the problem of inability to produce T-shaped prefabricated piles, etc., and achieve the effect of easy implementation, energy saving, and improvement of steam curing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

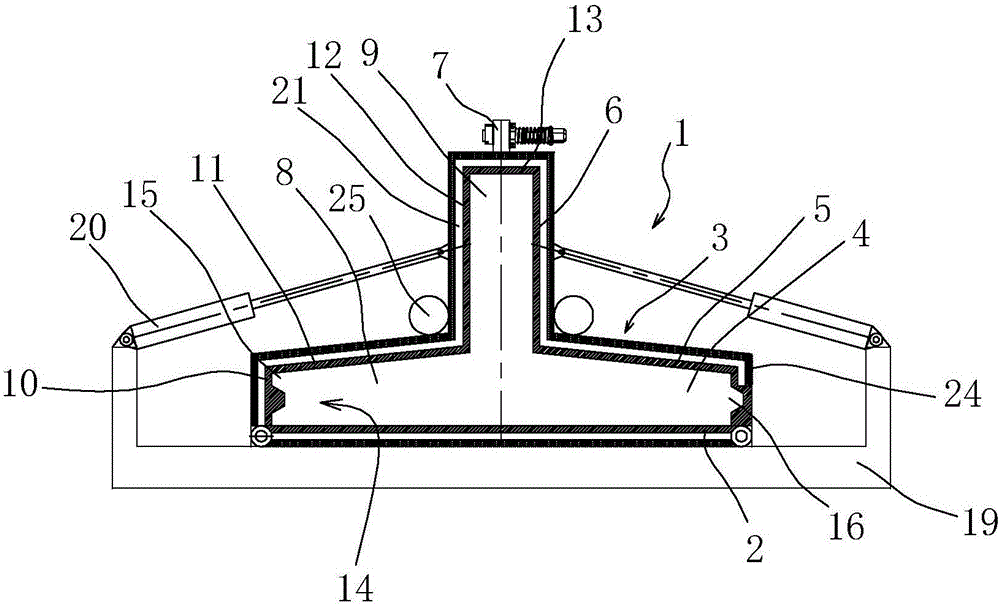

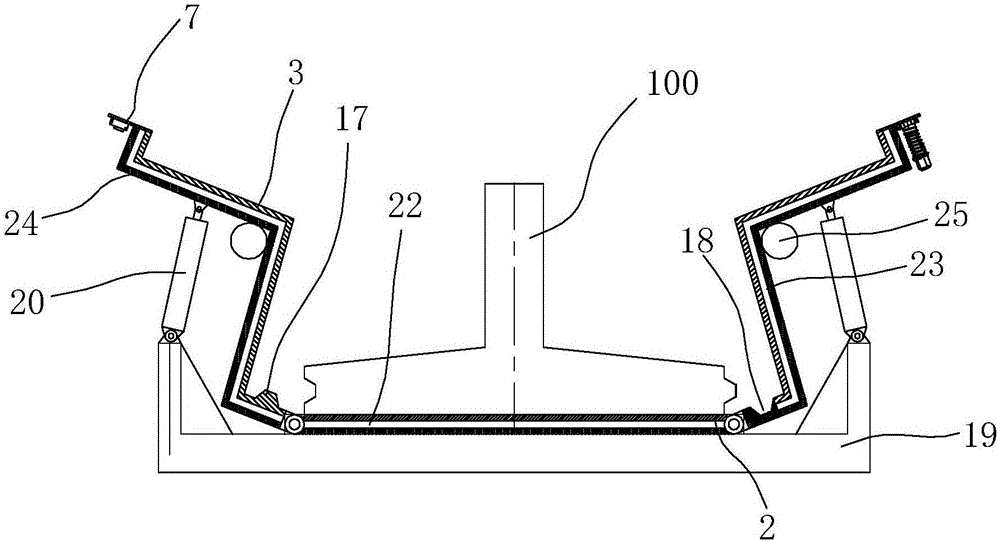

[0027] Such as figure 1 and figure 2 As shown, an in-situ opening and closing type T-shaped pile mold includes a mold body 1, and the mold body 1 includes a bottom template 2. The bottom template 2 can be fixed on the ground or on a machine base, and the two ends of the bottom template 2 are respectively A side mold strip assembly 3 is hinged and two side mold strip assemblies 3 are symmetrically distributed along the center line of the bottom formwork 2, and the side mold strip assembly 3 can rotate along the hinge with the bottom formwork 2, when the two side mold strip assemblies When the mold strip assemblies 3 are close to each other, the ends of the two side mold strip assemblies 3 away from the bottom formwork 2 can be detachably connected to each other so that a T-shaped molding cavity 4 is formed inside the mold body 1. When the two side mold strip assemblies 3 are mutually The T-shaped pile in the molding cavity 4 is separated from the side mold strip assembly 3 wh...

Embodiment 2

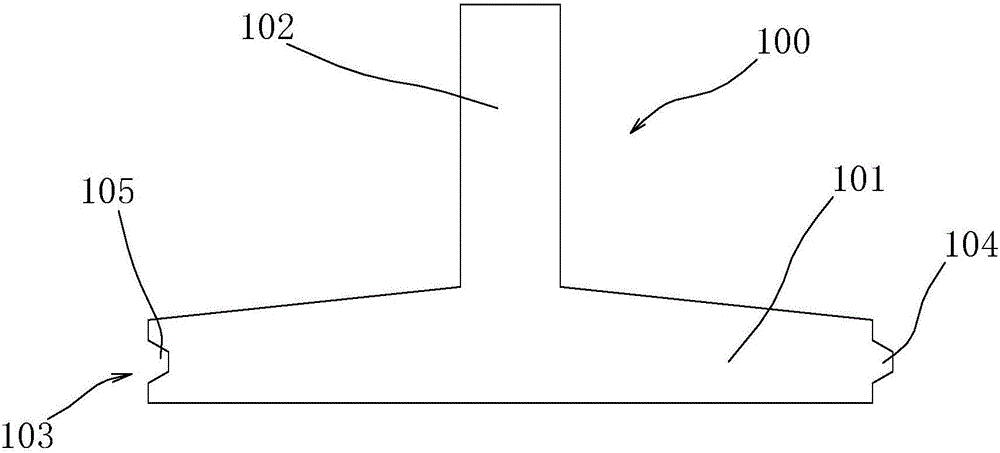

[0034] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 1 and figure 2 As shown, the inner wall of the mold body 1 is provided with a concave-convex bayonet forming mechanism 14, and the concave-convex bayonet forming mechanism 14 makes the end of one of the transverse pile forming regions 8 form an inwardly concave concave forming region 15, making the other lateral The end of the pile forming area 8 forms an outwardly convex forming area 16 . to produce graphs image 3 T-pile 100 with connection structure 103 is shown. The connecting structure 103 can connect the transverse piles 101 to each other so as to realize the connection of the T-shaped piles 100 .

[0035] Specifically, the concave-convex bayonet forming mechanism 14 includes a forming protruding bar 17 protruding from one of the transverse forming die bodies 5 and a forming groove 18 recessed in the other transverse forming ...

Embodiment 3

[0040] Those skilled in the art should know that in the prefabricated pile production process, after the cloth is finished, the prefabricated pile in the mold should be steam-cured at high temperature to improve the structural strength of the prefabricated pile. The prior art is to hang the mold into the steam-cured pool, use high-temperature steam to heat the mold and the prefabricated piles in the mold to achieve the effect of high-temperature steam curing. The working efficiency of this steam curing method is low, and the steam heat needs to enter the mold from the mold, and the energy consumption is high.

[0041] The structure and working principle of this embodiment and embodiment 2 are basically the same, the difference is that, as figure 1 and figure 2 As shown, the mold body 1 is provided with a steam-curing channel assembly 21 through which steam can be introduced to heat the inside of the mold body 1 . Steam is introduced into the steam curing channel assembly 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com