Light-curing-continuously-improving oxygen-permeation forming device

A molding device and light curing technology, applied in the direction of additive processing, etc., can solve the problem of continuous curing and molding, and achieve the effect of preventing the curing of the photosensitive resin in the blind area, improving the success rate and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

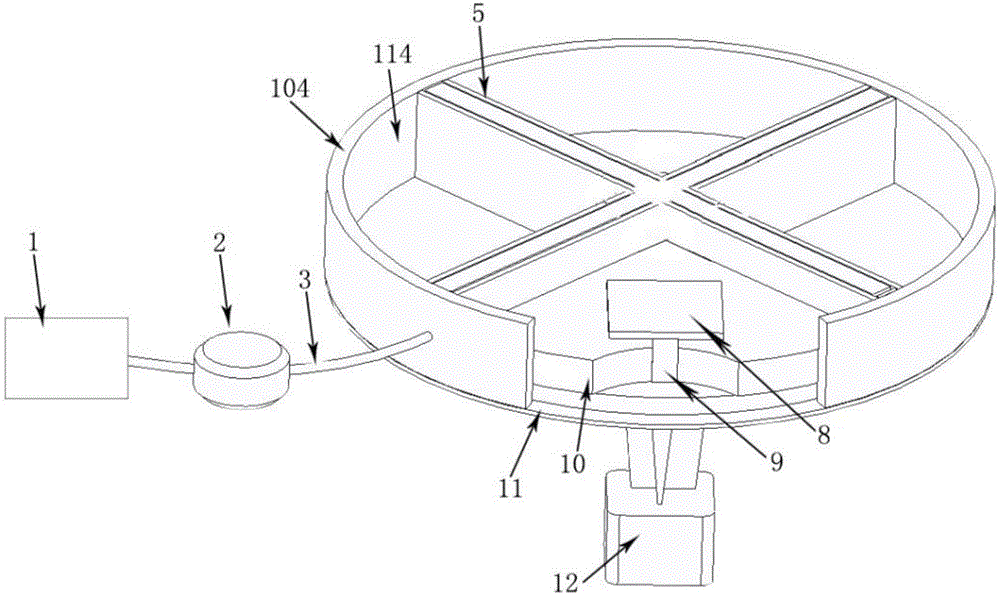

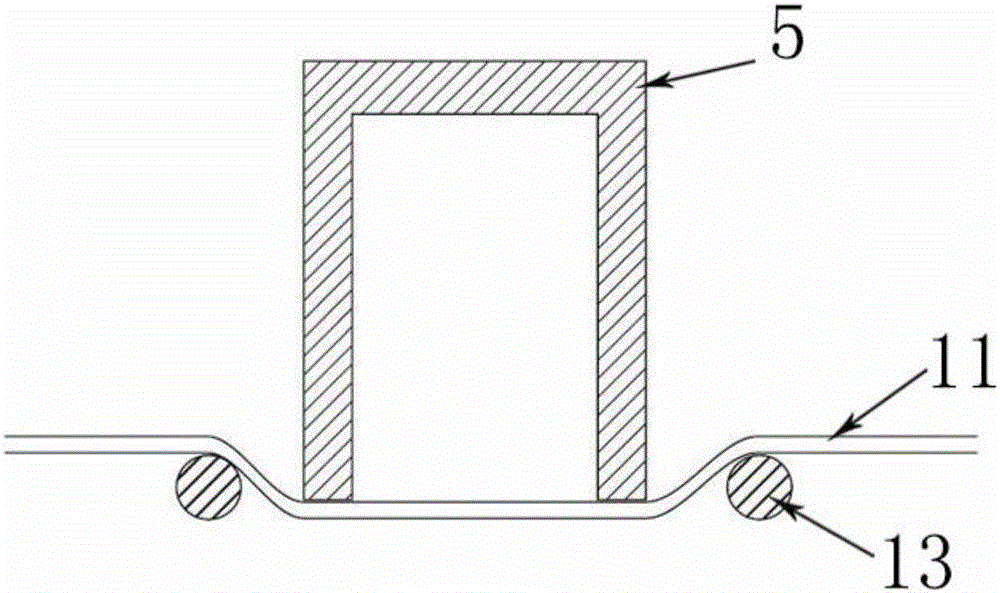

[0032] Such as figure 1 and figure 2 As shown, in this embodiment, the resin tank 114 is a circular structure, two oxygen tanks 5 are fixed on the side wall 104 of the resin tank 114, and the light-transmitting and oxygen-permeable film / layer 11 is only attached to the bottom of the resin tank 114, The driving device is located at the bottom of the light-transmitting and oxygen-permeable film / layer 11, and drives and connects the light-transmitting and oxygen-permeable film / layer 11 to rotate in the horizontal plane, thereby causing different parts of the light-transmitting and oxygen-permeable film / layer 11 to contact the oxygen tank 5, when When the oxygen concentration on the surface of the light-transmitting and oxygen-permeable film / layer 11 is low, oxygen diffuses from the oxygen tank 5 to the surface of the light-transmitting and oxygen-permeable film / layer 11, so that the blind area on the surface of the light-transmitting and oxygen-permeable film / layer 11 exists sta...

Embodiment 2

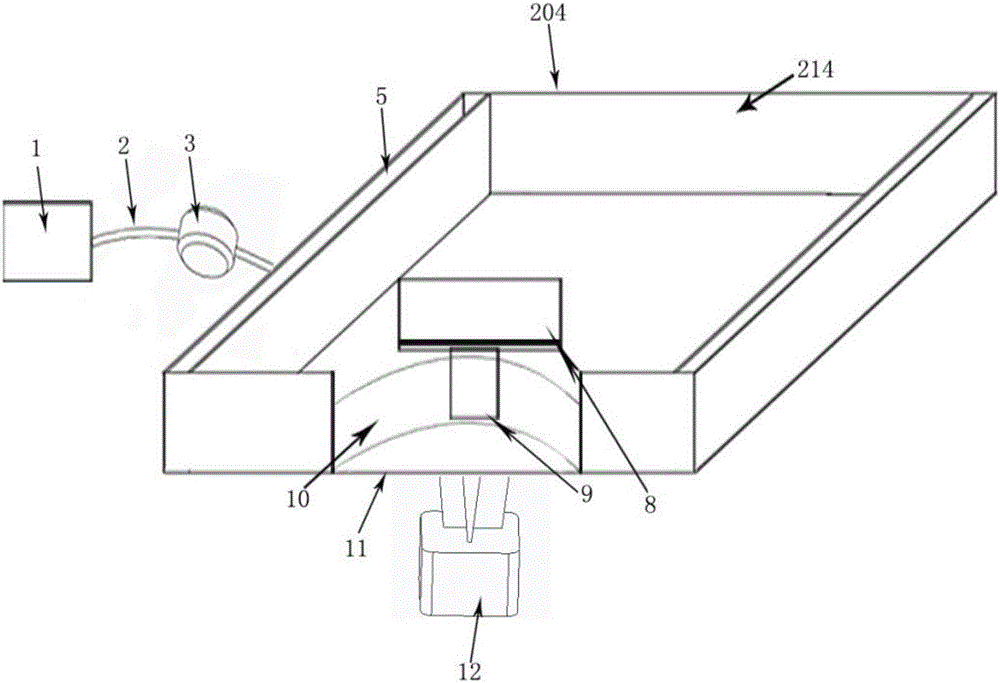

[0037] Such as image 3 As shown, in this embodiment, the resin tank 214 has a square structure; the driving device drives the connecting light-transmitting and oxygen-permeable film / layer 11 to reciprocate in the horizontal direction, and the rest of the technical features are the same as those in Embodiment 1.

[0038] In this embodiment, the driving mode of the driving device may be adhering friction driving or directly driving through a connecting rod.

Embodiment 3

[0040] Such as Figure 4 As shown, in this embodiment, the resin tank 314 has a circular structure, and the light-transmitting and oxygen-permeable film / layer 11 is fixedly connected to the side wall 304 of the resin tank 314 . An oxygen tank 5 is arranged inside the resin tank 314, and the oxygen tank 5 and the resin tank 314 are fixed separately, and the driving device drives the side wall 304 connected to the resin tank 314 to rotate in the horizontal plane, driving the light-transmitting and oxygen-permeable film / layer 11 in the horizontal plane Internal rotation causes different parts of the light-transmitting and oxygen-permeable film / layer 11 to be in contact with the oxygen tank 5. When the oxygen concentration on the surface of the light-transmitting and oxygen-permeable film / layer 11 is low, oxygen diffuses from the oxygen tank 5 to the light-transmitting and oxygen-permeable On the surface of the film / layer 11, the stable existence of blind areas on the surface of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap