Electric correction device

A deviation-correcting device and electric technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of high response speed requirements of the central control system, poor control of hardware costs, and impact on equipment service life, so as to facilitate maintenance , low strength requirements, and the effect of reducing the failure rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

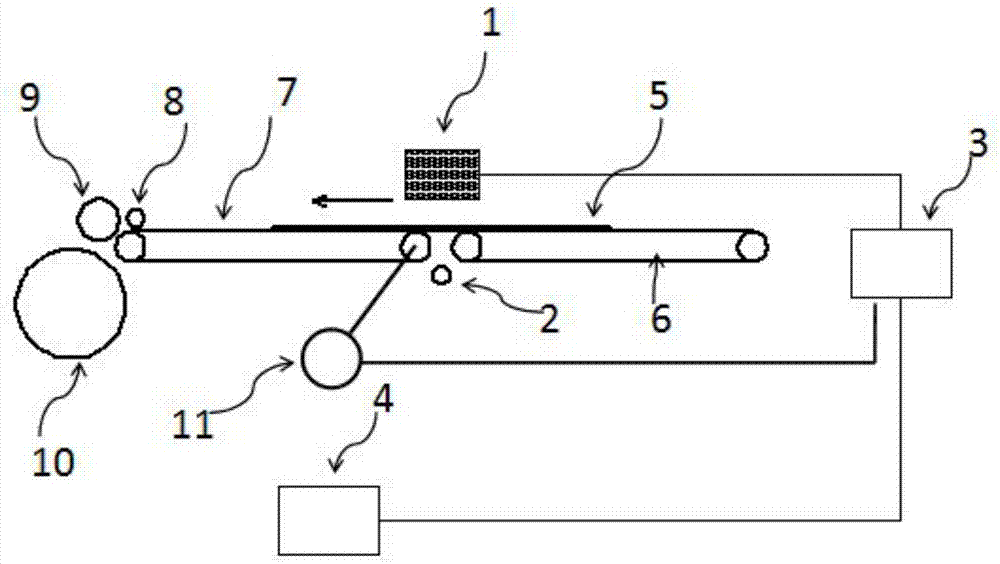

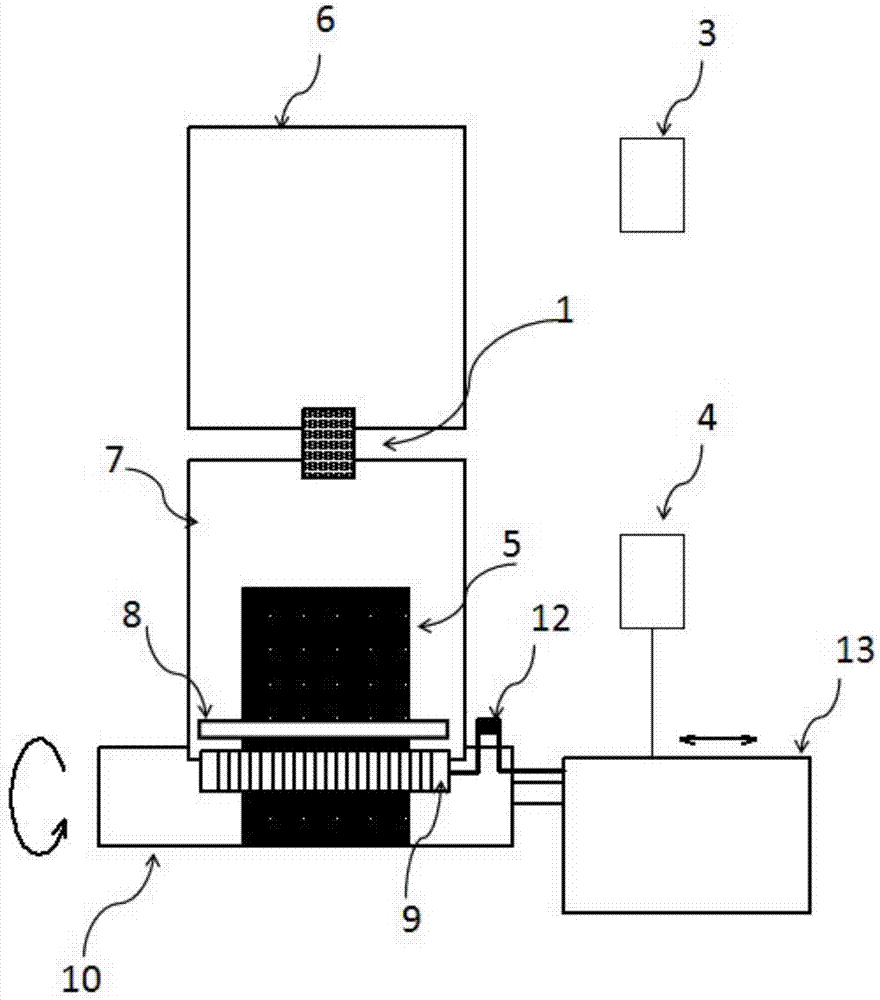

[0027] see Figure 1 to Figure 3 , The electric correction device of the present invention comprises front conveyor belt 6, rear conveyor belt 7, pressure roller 8, multi-sheet pressure roller 9, drum 10, cabinet 13, visual sensor 1, parallel light source 2, high-speed counter 11, industrial computer 3 and PLC4.

[0028] The front conveyor belt 6 and the rear conveyor belt 7 are used for conveying the rubber material 5 . The rubber material 5 is pasted on the drum 10 through the pressure roller 8 and the multi-piece pressure roller 9 .

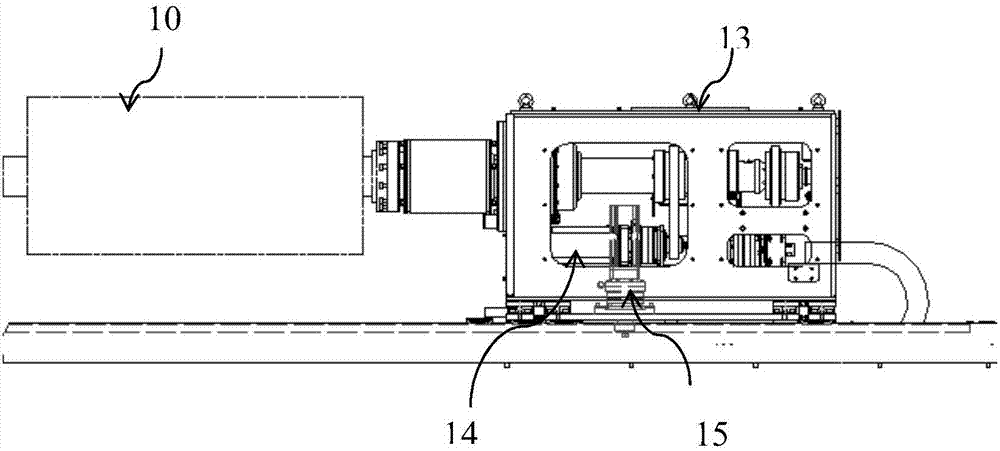

[0029] Such as image 3 As shown, the inside of the cabinet 13 is provided with a rotary motor 14 and a horizontal movement motor 15, the rotary motor 14 is connected with the central shaft of the drum 10 to realize the rotation of the drum 10, and the bottom of the cabinet 13 is slidably installed throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com