Corrugator with automatic pressure mechanism

A pressure mechanism, corrugating machine technology, applied in lamination, lamination device, lamination auxiliary operation, etc., can solve the problem that the thickness change cannot be accurately measured, and achieve the effect of reasonable structure, simple operation and reasonable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

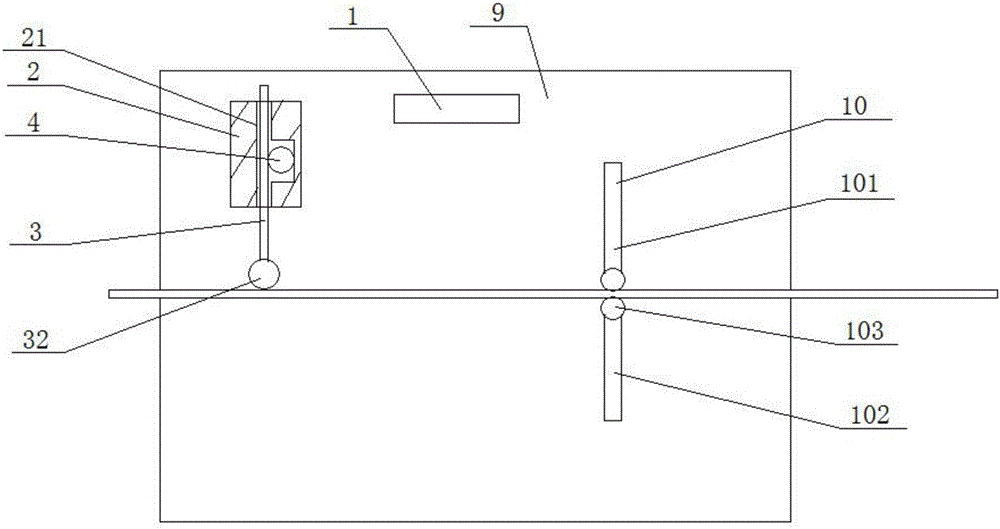

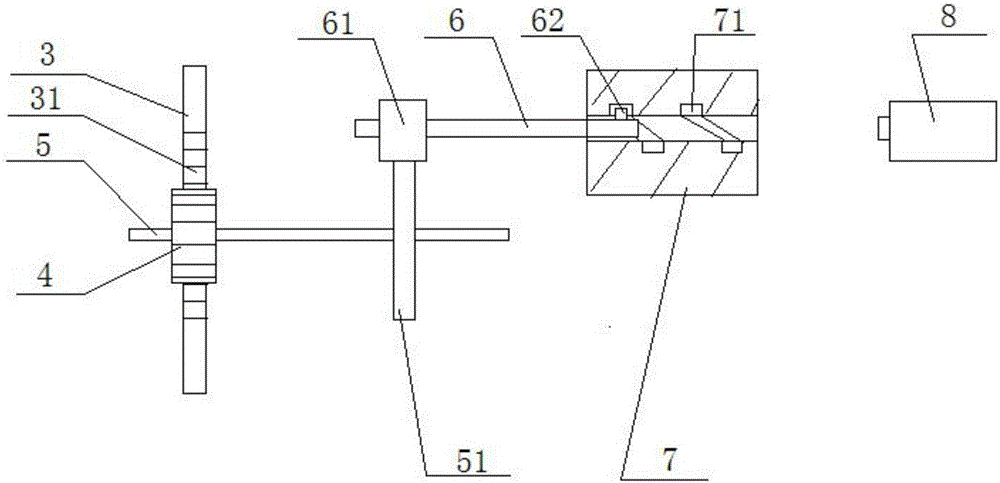

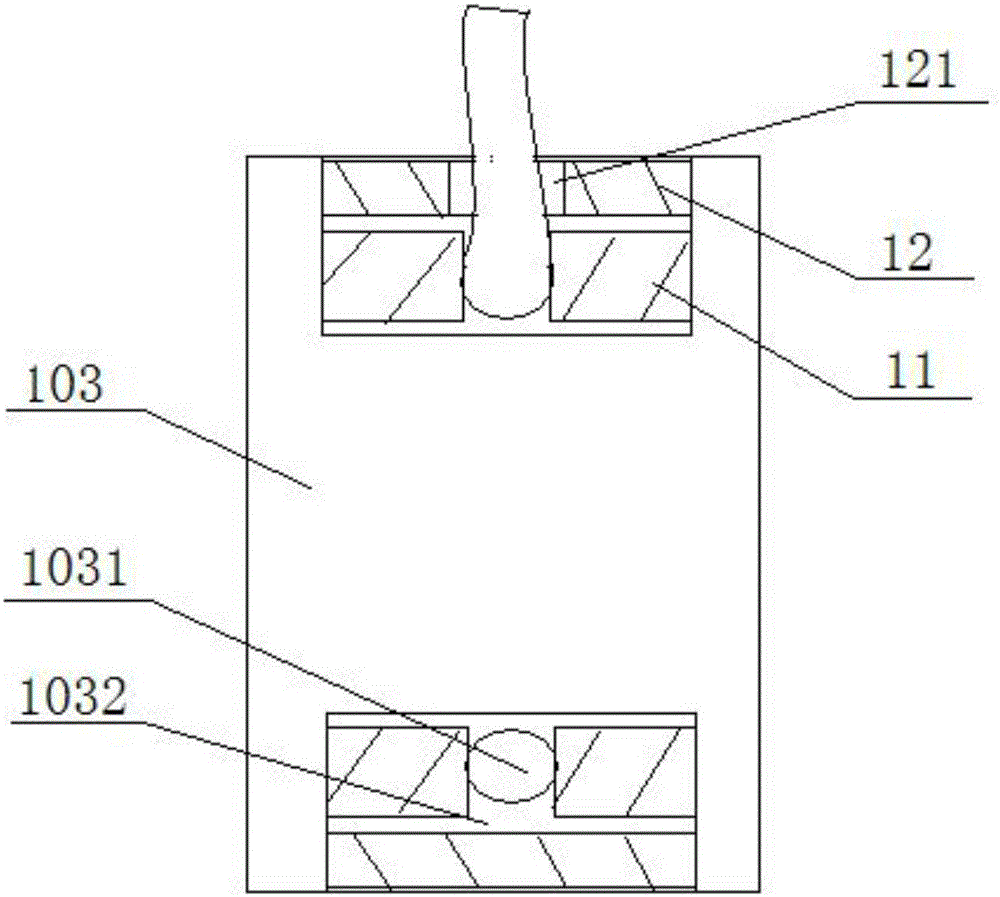

[0022] A corrugator with an automatic pressure mechanism, as shown in the figure, includes a corrugator body 9, including a thickness detection mechanism, a pressing mechanism, and a controller 1 connected to the thickness detection mechanism and the pressing mechanism. The thickness detection mechanism includes a fixed plate 2, fixed The plate 2 is fixed on the main body 9 of the corrugating machine. There are nine holes 21 arranged on the fixed plate 2. The holes 21 are vertically arranged in a straight line with the paper surface of the corrugated base paper. The formed straight line is perpendicular to the movement direction of the corrugated base paper. There is a telescopic rod 3 in contact with the surface of the corrugated base paper. A rack 31 is arranged on the telescopic rod 3. A first gear 4 cooperating with the rack 31 is installed in the hole 21. Each first gear 4 is connected to a rotating shaft. 5 and drive the rotating shaft 5 to rotate, the rotating shaft 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com