High speed gravure printing machine

A gravure printing machine, high-speed technology, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of high consumption of air conditioning system, defective products or uneven printing, non-parallel installation of guide rollers, etc. Improve overprint accuracy, good effect, and improve the effect of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

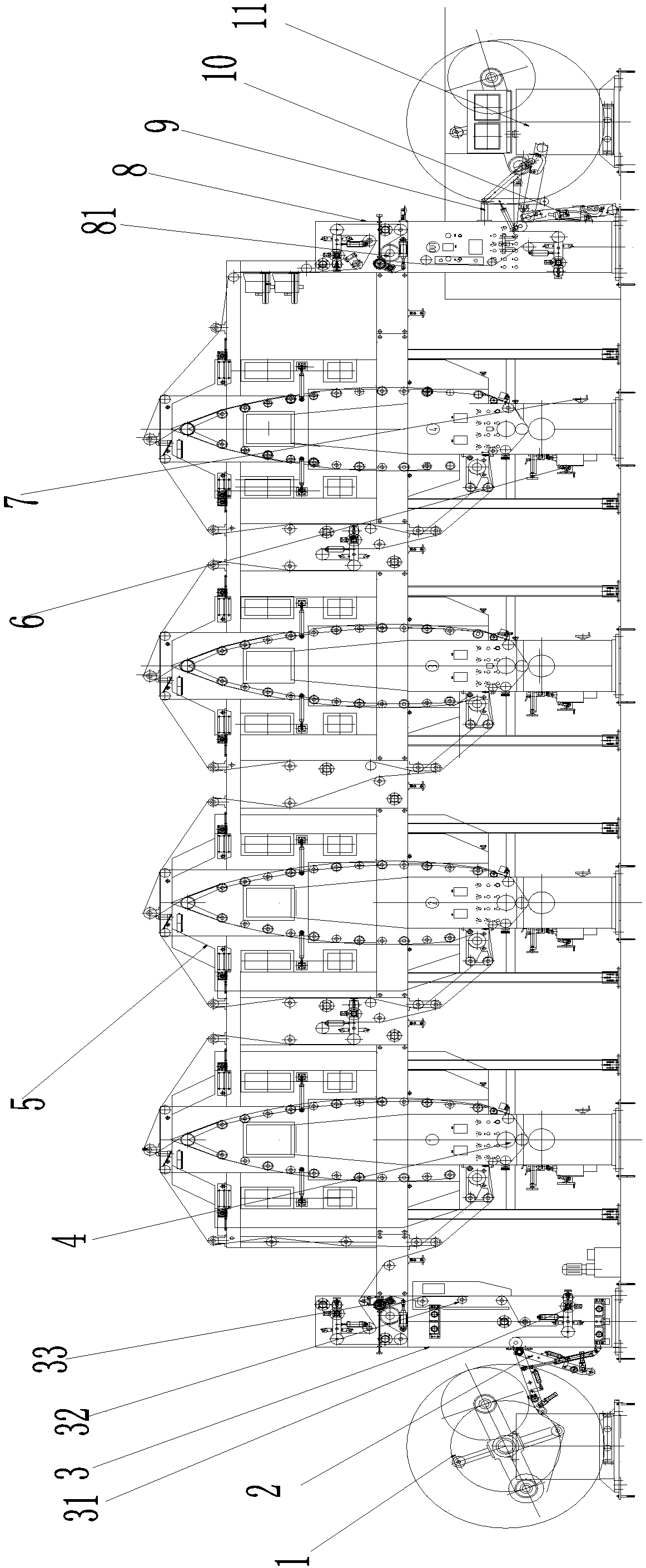

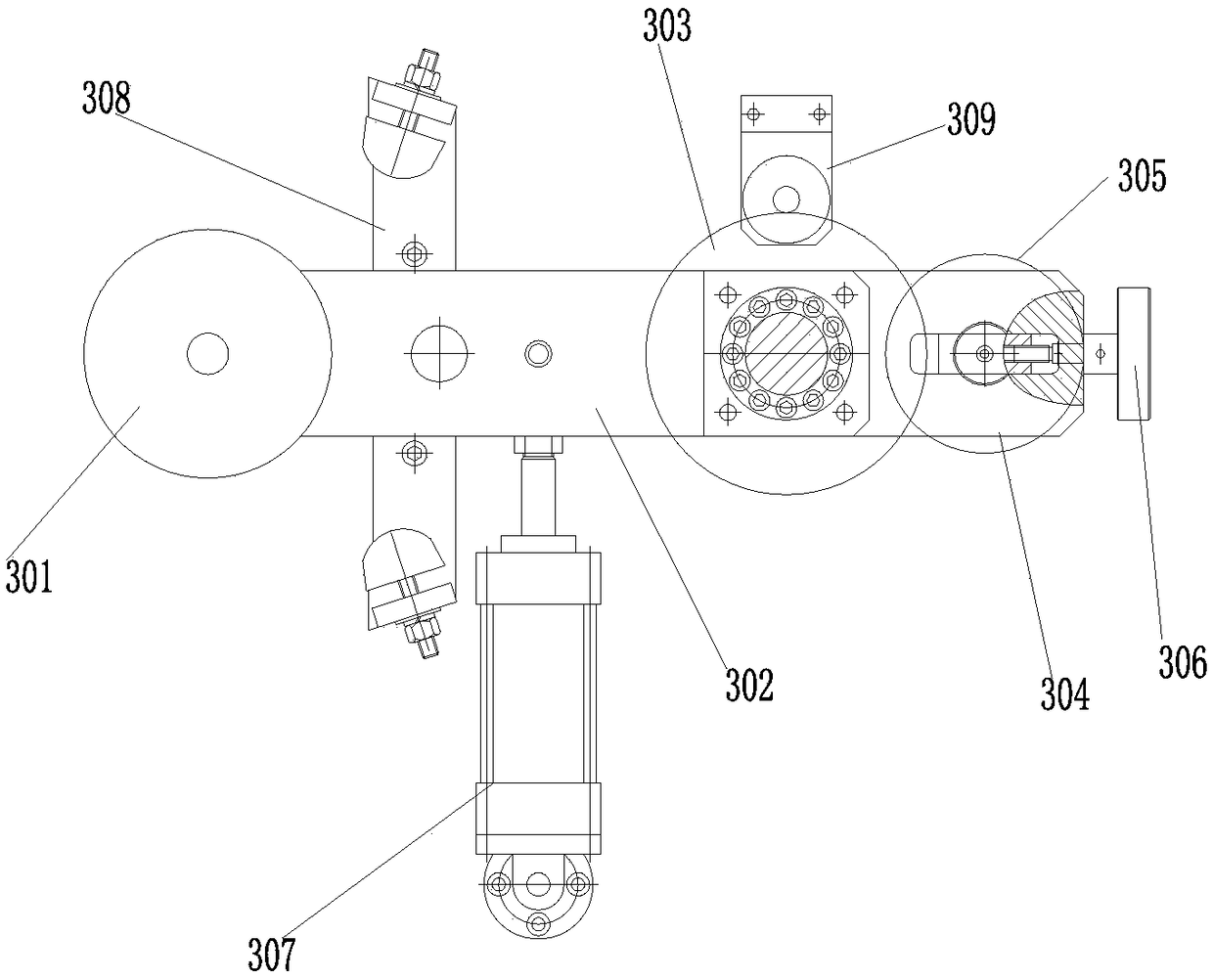

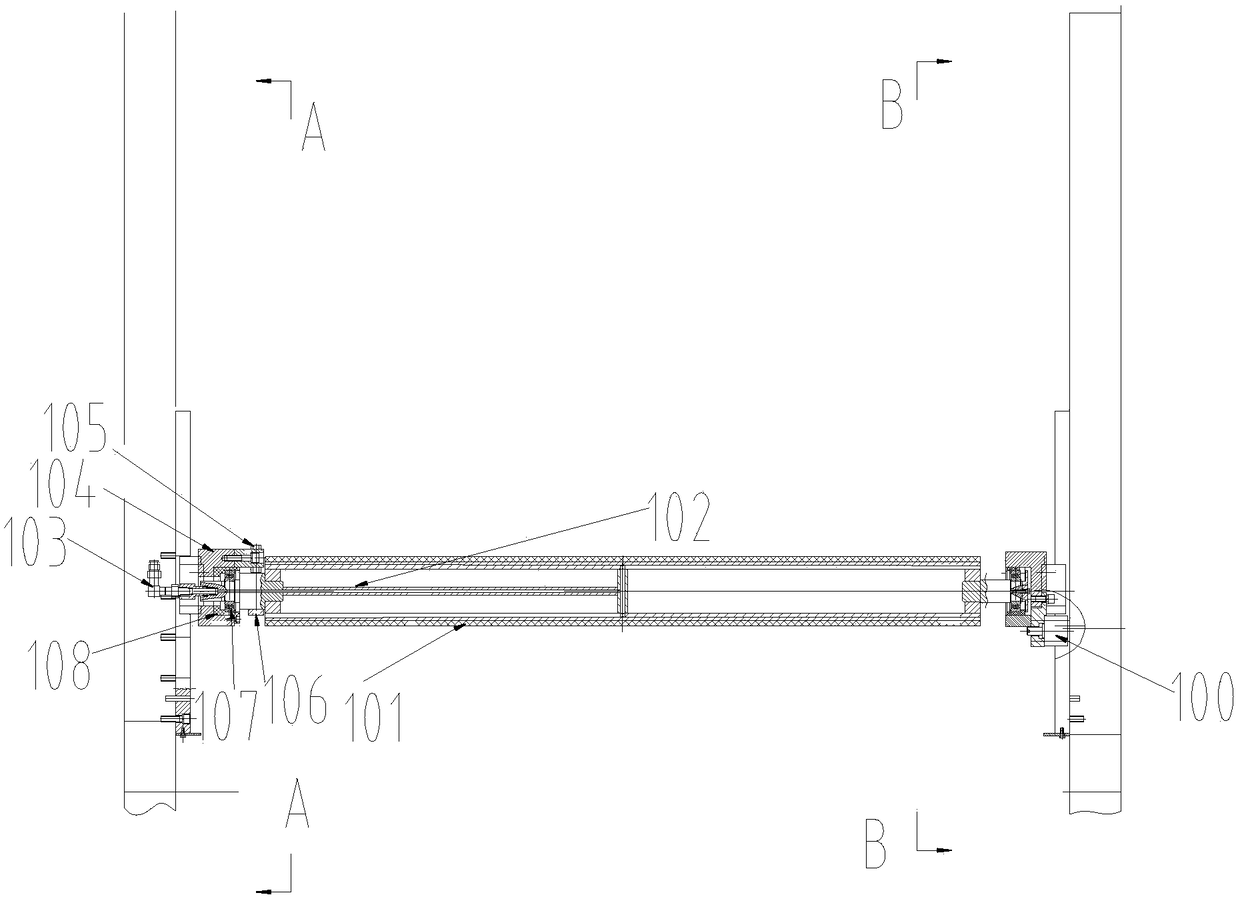

[0029] Refer to attached figure 1 As shown, the high-speed gravure printing machine disclosed in the present invention includes a winding device 11, an unwinding device 1 and at least one set of embossing devices between the rewinding device and the unwinding device, and each group of embossing devices consists of The printing device 4 and the oven heating device 5 are composed of each group of embossing devices connected by transmission guide rollers, and the unwinding traction part 3 connected by transmission guide rollers is installed between the embossing device 4 and the unwinding device, and the embossing device Between the rewinding device and the rewinding device, a rewinding traction section 8 connected by a transmission guide roller is installed, and at least one pendulum roller device 31 for controlling the tension of the printing substrate is arranged on the unwinding traction section 3 and the rewinding traction section 9 , the printing device includes a back pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com