Automatic decoupling mechanism for vehicle coupler

一种车钩、自动的技术,应用在铁路车体部件、铁路车辆联轴器配件、铁路联轴器等方向,能够解决减小侧向力等问题,达到提高稳定性、降低维护成本、提高响应速度和稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

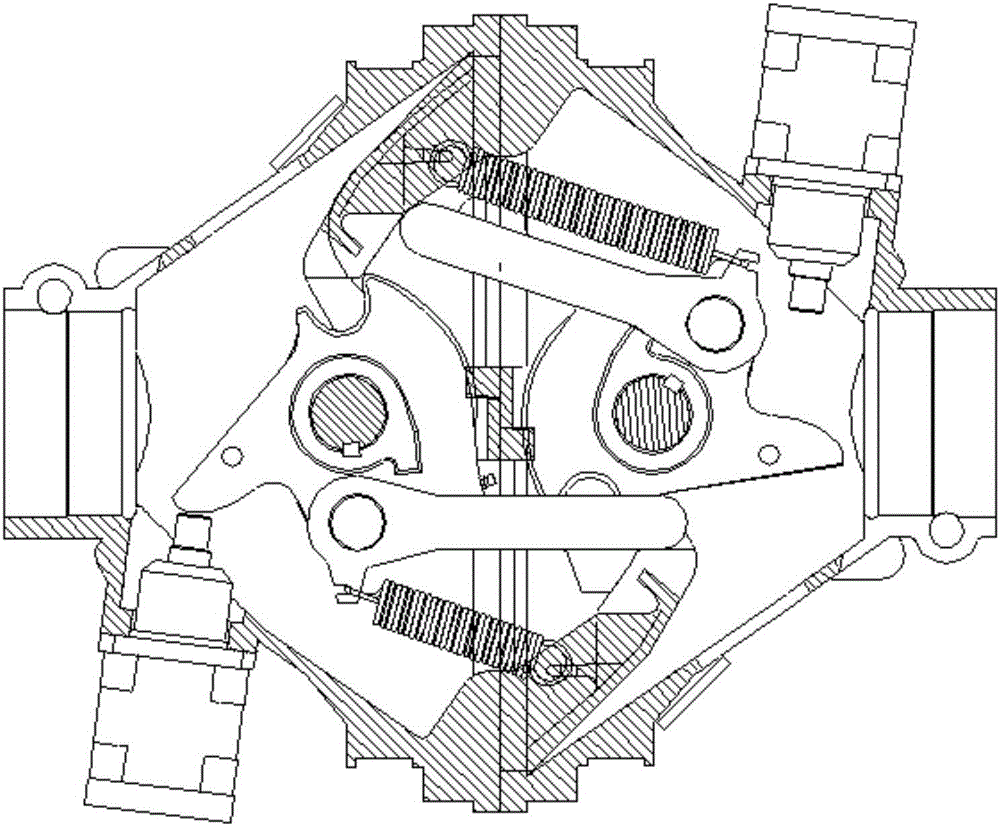

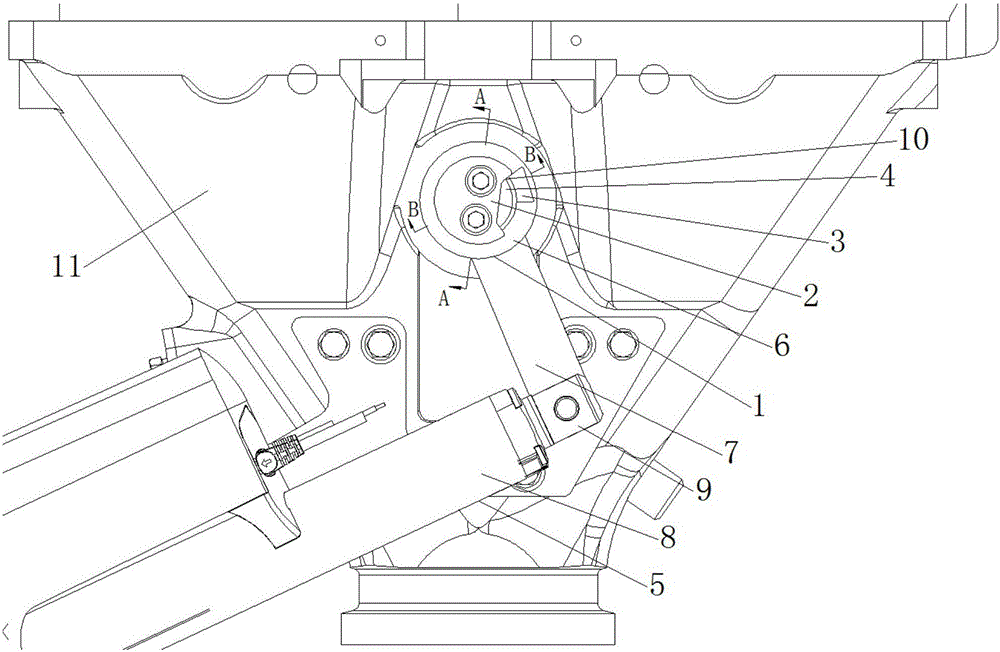

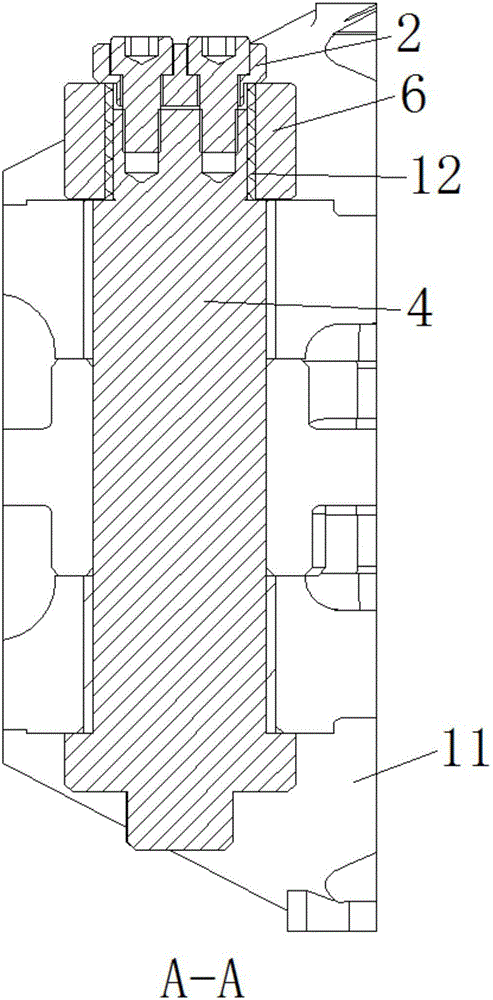

[0032] Example: such as Figure 2 to Figure 4 As shown, a coupler automatic uncoupling mechanism includes a knuckle shaft 4 and a drive unit 5, the drive unit 5 includes a cylinder 8 hinged on the coupler body 11, and a telescopic member 9 that can move axially along the cylinder 8; The coupler automatic uncoupling mechanism also includes a first rotating part 1, a boss 3 and a boss stopper 10, wherein the first rotating part 1 includes a crank 7 hinged to the telescopic part 9, and a rotating part 6 fixedly connected to the crank 7 , the rotating part 6 is sleeved on the knuckle shaft 4; the unidirectional drive of the telescopic member 9 by the drive unit 5 impels the rotating part 6 to drive the knuckle shaft 4 to rotate in one direction through the contact between the boss 3 and the boss stopper 10 , to complete the coupler uncoupling; after the drive unit 5 drives the telescopic member 9 to return, the rotation of the knuckle shaft 4 to complete the coupling of the couple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com