Universal cabinet body of locomotive air braking cabinet

An air brake and cabinet technology, which is applied in the direction of pneumatic brakes, brakes, brake components, etc., can solve the problems of diversification and incompatibility of cabinets, and achieve the effects of avoiding repeated waste, saving materials, and facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

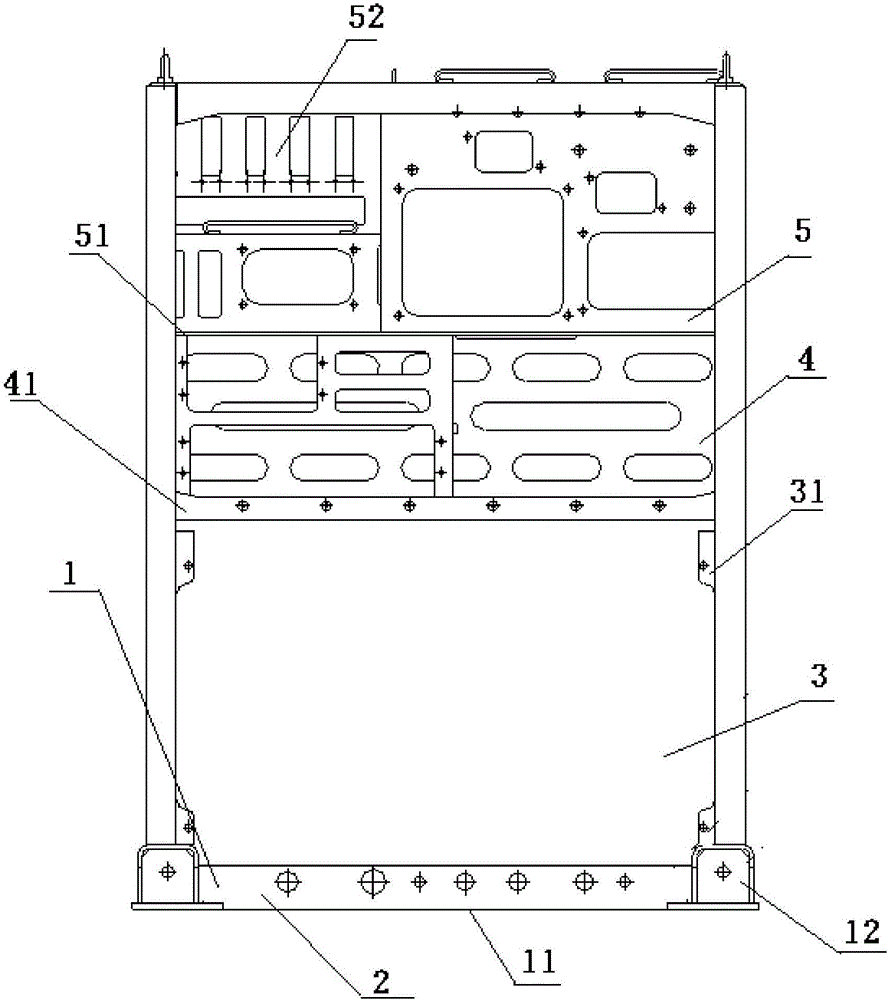

[0021] Embodiment 1: This kind of locomotive air brake cabinet has a general cabinet body. The connecting plate 2 of the base 1 of the cabinet body is provided with an installation interface and a pipeline connection interface for connecting the brake cabinet to the locomotive. The inside of the cabinet body is provided with brake components. Module, microcomputer control component module, auxiliary component module and electrical component module, the four modules are arranged from bottom to top to form four installation layers; the bottom to top arrangement of the installation layers of the four modules is the installation layer 3 of the brake component module , The installation layer of the microcomputer control component module 4, the installation layer of the auxiliary component module, and the installation layer of the electrical component module. Base 1 is made up of base plate 11, underframe 12 and connecting plate 2, and connecting plate 2 is connected with underframe ...

Embodiment 2

[0022] Embodiment 2: This kind of locomotive air brake cabinet has a general cabinet body. The connecting plate 2 of the base 1 of the cabinet body is provided with an installation interface and a pipeline connection interface for connecting the brake cabinet to the locomotive. The inside of the cabinet body is provided with brake components. Modules, microcomputer control component modules, auxiliary component modules and electrical component modules, two of which are installed on one installation layer, and the other two modules are respectively installed on one installation layer, and the three installation layers are arranged from bottom to top. The order of the three installation layers from bottom to top is the installation layer 3 of the brake element module, the installation layer 4 of the microcomputer control component module, and the installation layer 5 of the auxiliary component module and the electrical component module. Base 1 is made up of base plate 11, underfr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com