Automatic efficient heat energy recovery system applied to pharmaceutical industry

A heat recovery and high-efficiency technology, applied in control systems, preheating, lighting and heating equipment, etc., can solve the problems of no systematic multi-station automatic joint control and monitoring records, safety and quality hidden dangers, heat energy cannot be recovered, etc. To achieve the effect of preventing risks caused by failures, avoiding failure maintenance and waste of energy consumption, and avoiding human error and tedious labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

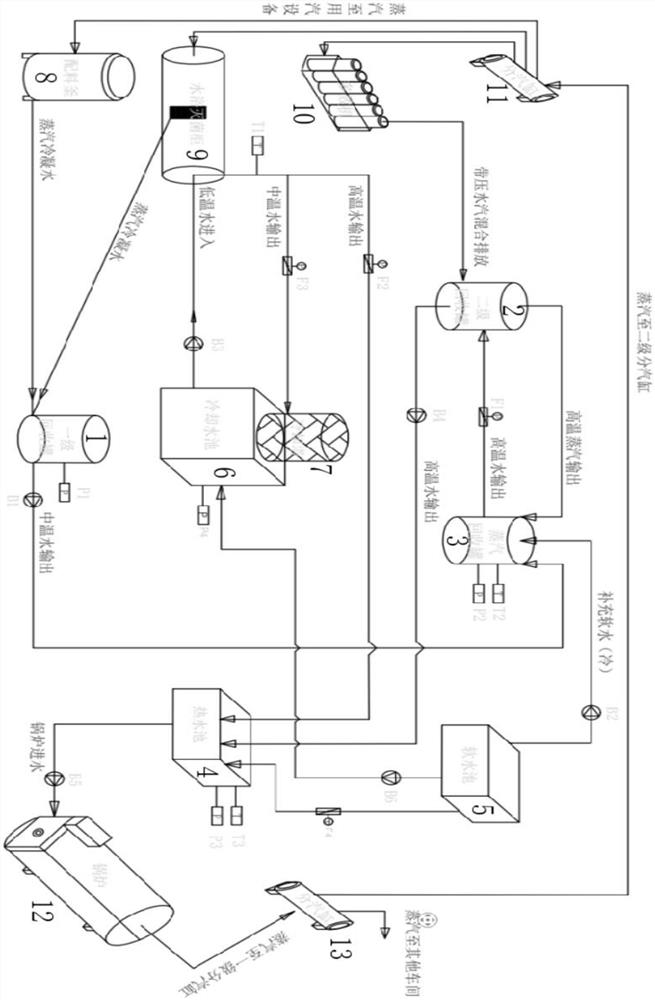

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0019] refer to figure 1 , an automatic high-efficiency heat energy recovery system used in the pharmaceutical industry, including a primary recovery tank 1, a secondary recovery tank 2, a steam recovery tank 3, a hot water pool 4, a soft water pool 5, a cooling water pool 6, a cooling tower 7, and a batching kettle 8. Water bath sterilizer 9, multi-effect machine 10, first sub-cylinder 11, boiler 12 and second sub-cylinder 13, first sub-cylinder 11 is connected with batching kettle 8, water bath sterilizer 9, multi-effect machine 10 , the batching kettle 8 and the water bath sterilizer 9 are connected with the primary recovery tank 1, the primary recovery tank 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com