Aseptic packaging machine

A technology for aseptic packaging and packaging, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of drug contamination risk, large contamination risk, etc. Accident reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

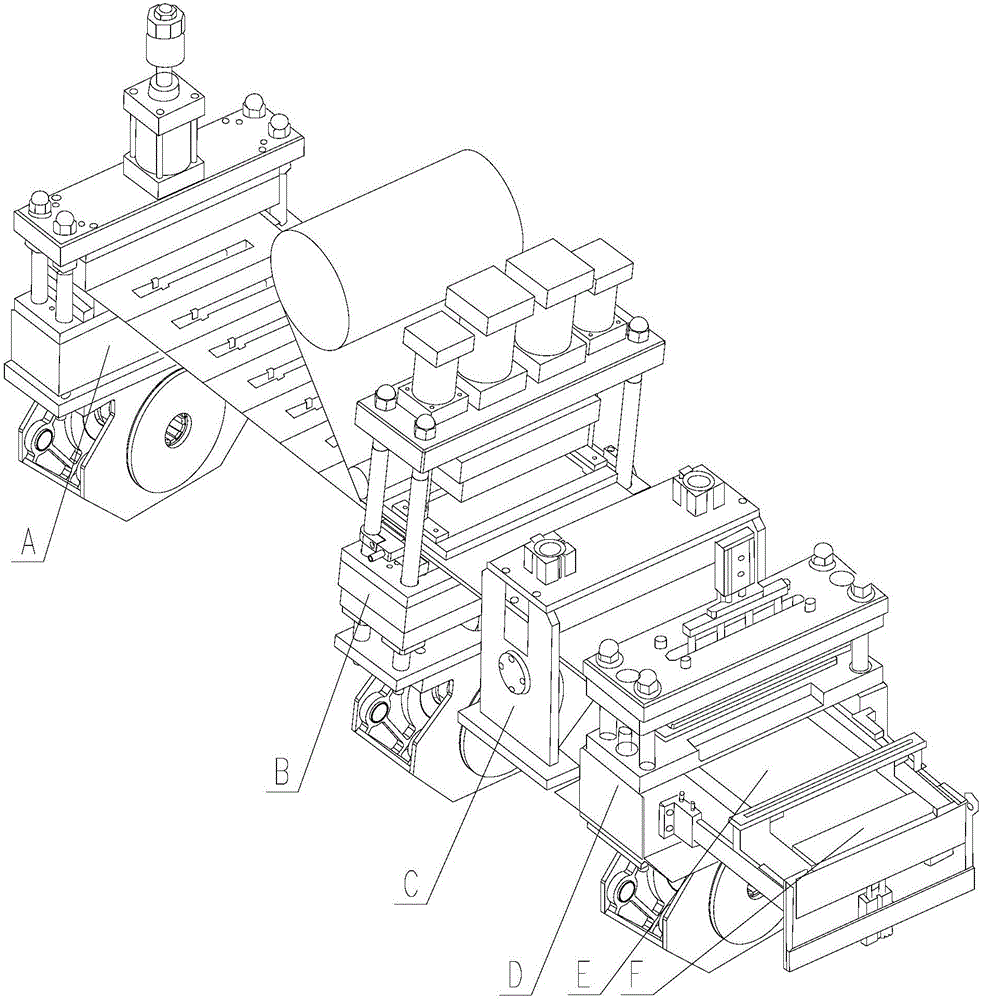

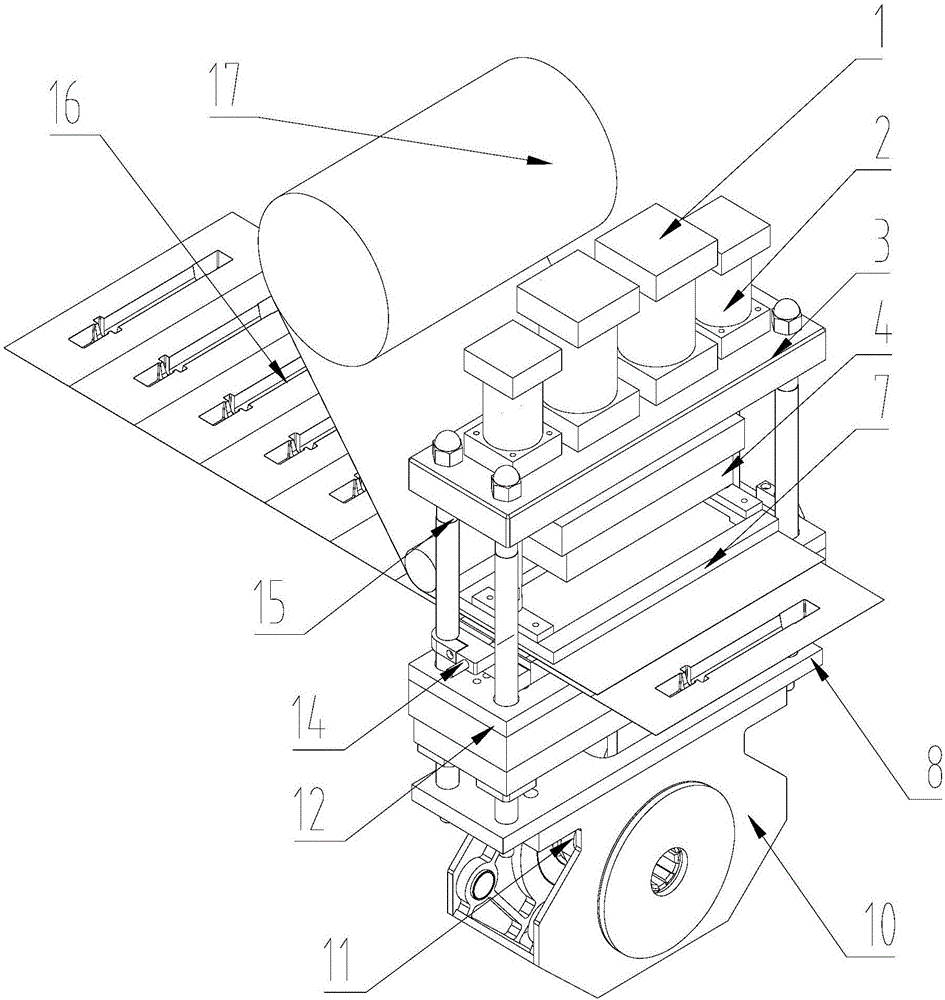

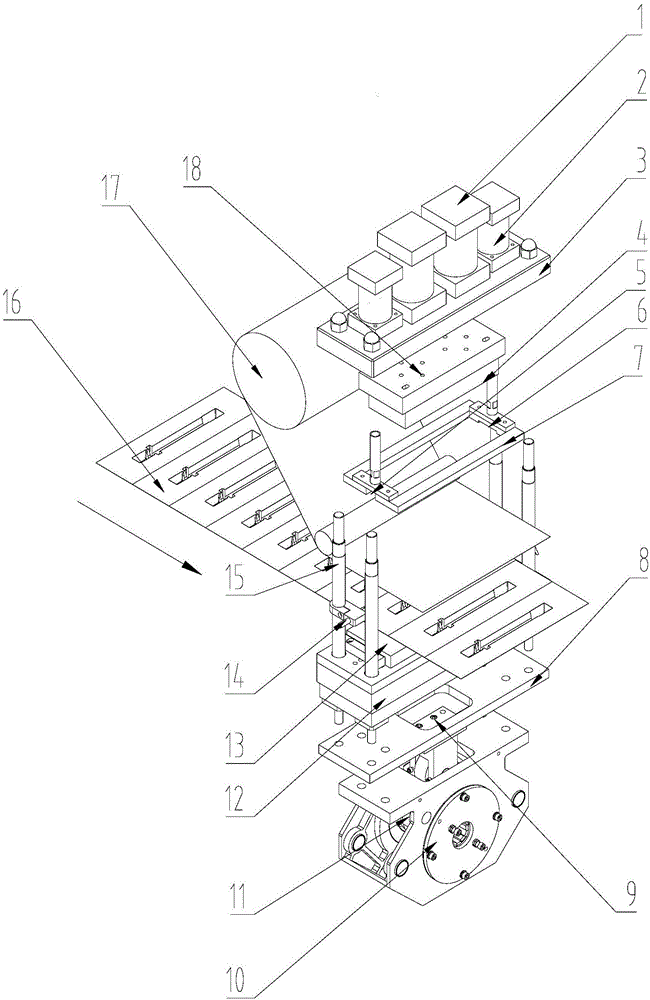

[0043] Specific embodiments of the present invention are shown in the accompanying drawings. The aseptic packaging machine includes a package forming device A, a traction device C, a punching device D, a conveying device E and a finished product collection device F; the package forming device A, the traction device The device C, the punching device D, the conveying device E and the finished product collecting device F are arranged in order to form an aseptic blister packaging machine; Blowing device B.

[0044] The heat-sealing blowing device B includes: a frame body, a pressing power mechanism, a heat-sealing structure, a gas blowing pipe 14, and a lifting power mechanism; The lower part is equipped with a heat-sealing structure on the pressing power mechanism and the lifting power mechanism. The gas blowing pipe 14 is installed on the frame; After the inlet pipe 14 is processed, it is combined to become a finished product.

[0045] The frame body includes: connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com