Car engine room CKD packing structure

A technology of packaging structure and machine compartment, applied in the field of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

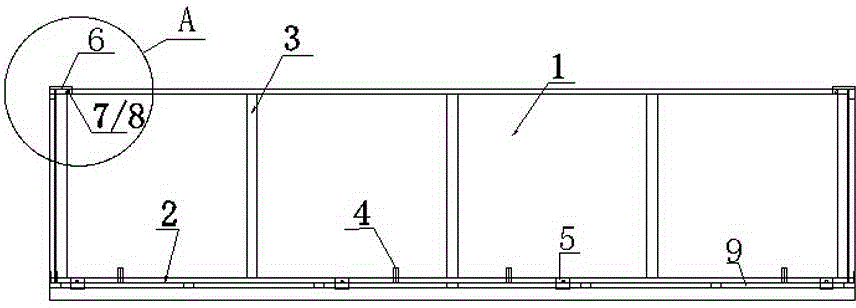

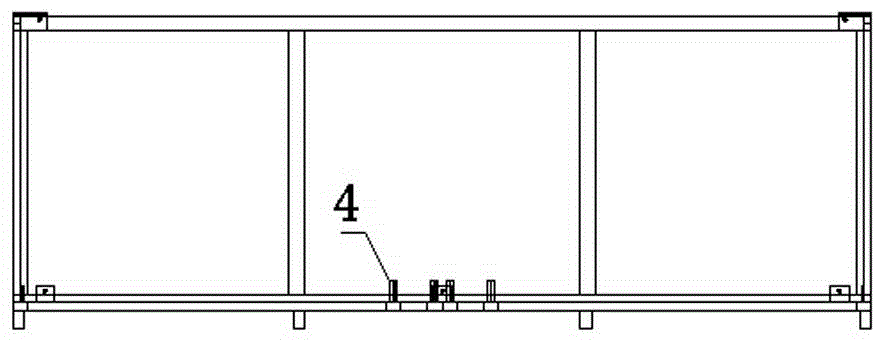

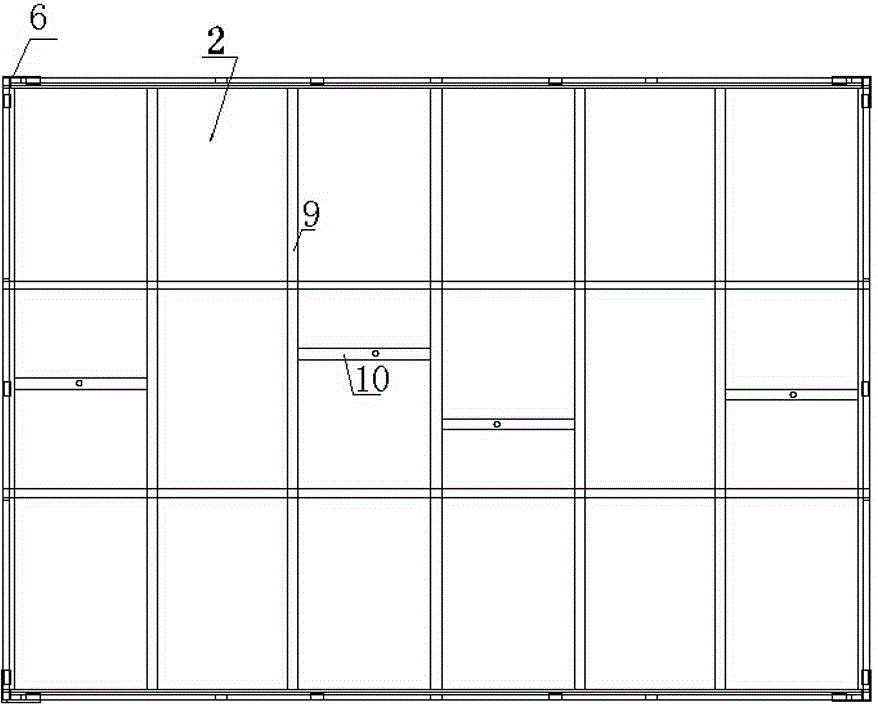

[0018] The present invention as figure 1 , 2 , 3, 4 shown.

[0019] A CKD packaging structure for a car cabin box, including an all-steel structure frame 1, the frame bottom 2 is welded by square steel pipes 9 and mesh sheets 10, and a plurality of positioning columns 4 are arranged on the plane of the frame bottom 2. Two positioning columns 4 correspond to the bottoms of two car engine compartments, and the frame 3 is welded by square steel pipes 9 plus mesh sheets 10, and the bottom edge of the frame 3 is connected to the corresponding frame bottom 2 edges by a hinge 5, wherein Square steel tubes 9 are also arranged between the bottoms of the two corresponding frames 3 and the bottom 2 of the frame, so that the bottoms of the two corresponding frames 3 are higher than the other two corresponding frames 3, and the height dimension is one square steel tube 9 high.

[0020] The corner of frame 3 top is provided with through hole 7 in the frame, and two adjacent frames 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com