Automatic discharging and stacking equipment for automobile steel plate springs

An automobile steel plate and automatic cutting technology, which is applied to conveyor objects, stacking, transportation and packaging of objects, etc., can solve the problems of poor accuracy, low efficiency and high production cost, and achieve better use effect and save production. The effect of high cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

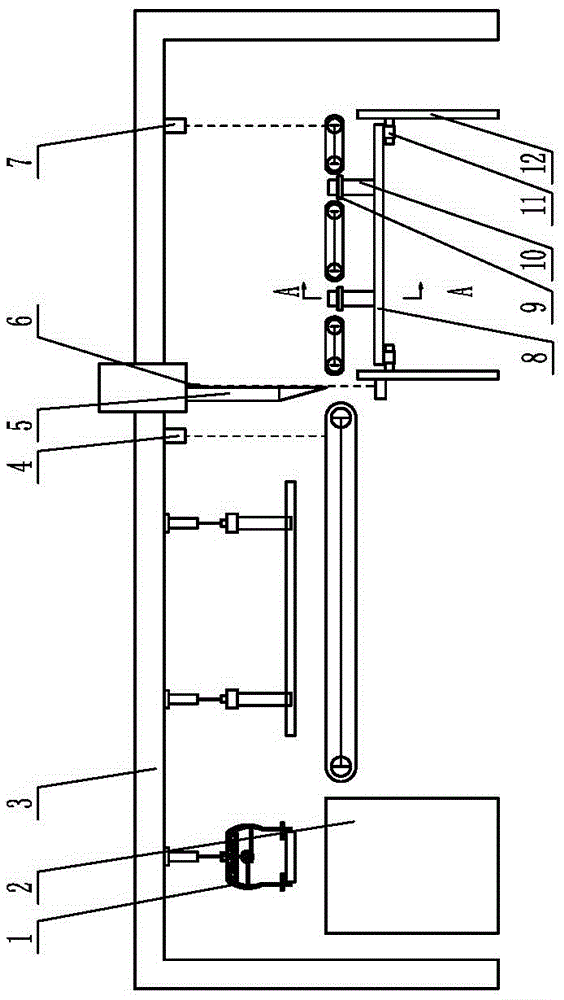

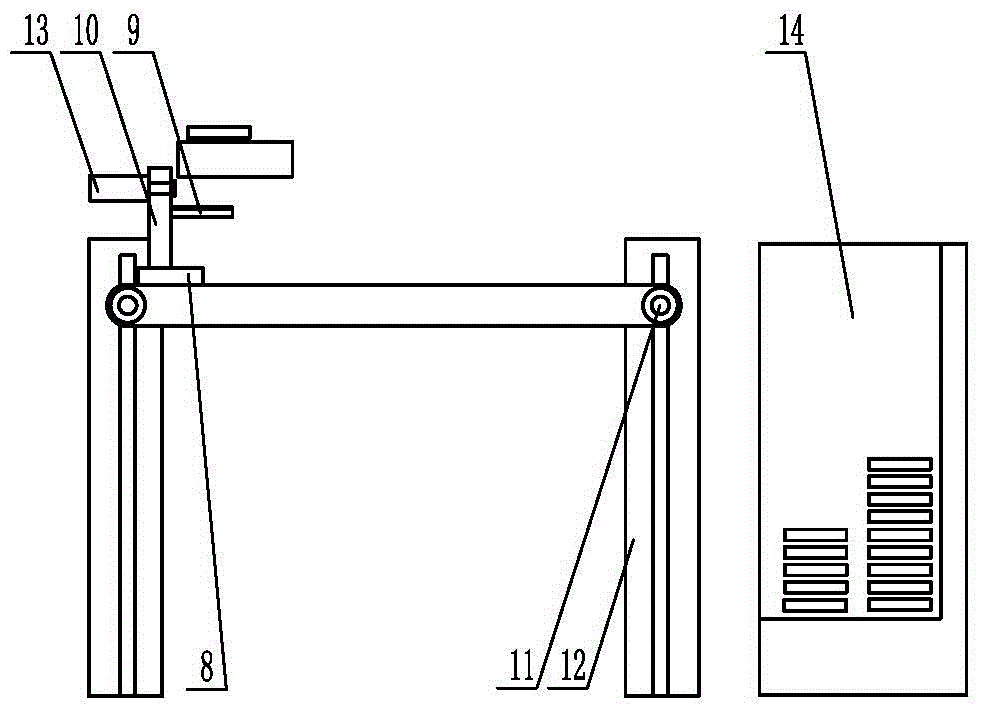

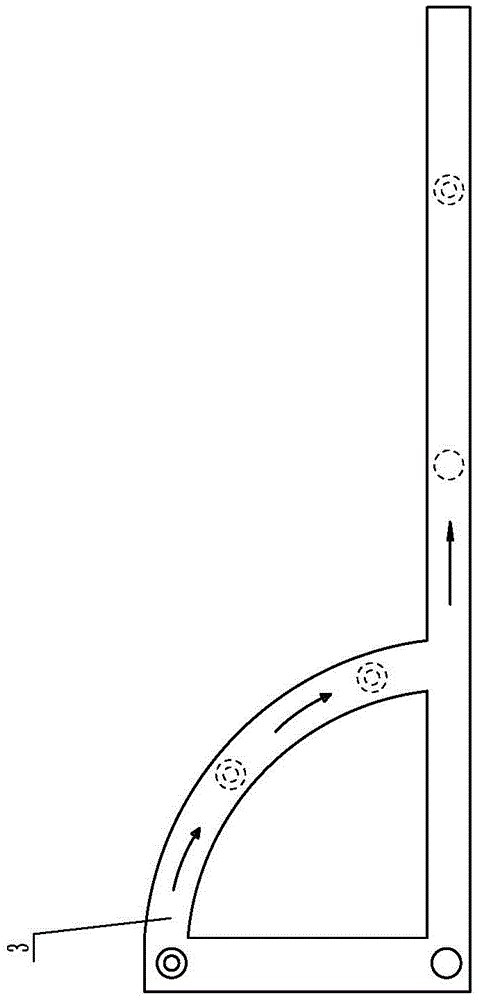

[0028] Such as figure 1 As shown, a kind of automatic unloading and coding equipment for automobile leaf springs is characterized in that it includes a slide rail bracket, a manipulator, a raw material bin, a material cutter, a coding device and a code bin, and one side of the material cutter under the slide rail bracket The raw material warehouse is set, and the other side of the material cutter under the slide rail bracket is set with a coding device. Two manipulators are arranged on the slide rail support, and the manipulators move along the slide rail support, and the manipulators extend into the raw material bin to clamp the leaf spring, and grab the leaf spring upward and take it out of the raw material bin. Two manipulators that grab raw materials, one of which only rotates, while the other first moves in an arc along the slide rail bracket to change the direction of the raw material. After the two manipulators complete the rotation, they run on the same track and in th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap