Stacking gripping device

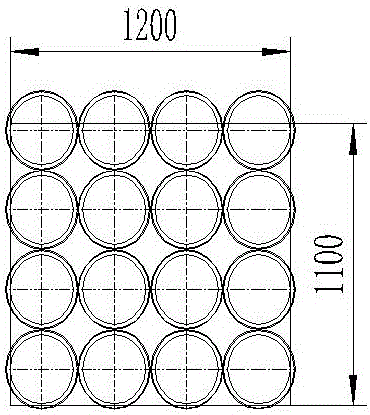

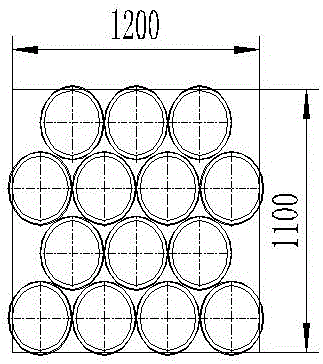

A grasping device and stacking technology, applied in the field of stacking machinery and equipment, can solve the problems of insufficient and reasonable utilization of pallet space, inconvenient disassembly and assembly, and troublesome, so as to achieve the effect of convenient and quick disassembly and assembly, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

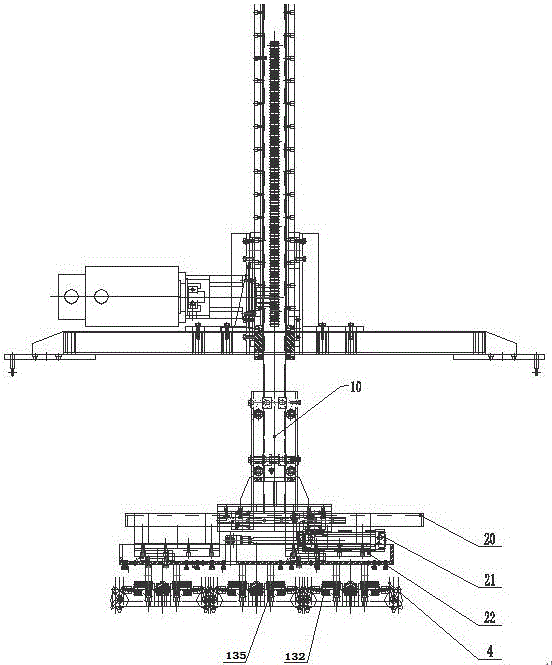

[0030] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 3-10 As shown, the present invention discloses a palletizing grabbing device, comprising: a floating lifting mechanism 10; a lifting plate 20 connected to the bottom of the floating lifting mechanism 10; a linear actuator is connected to the lifting plate 20, and the linear actuator is connected to a clamp The jaw fixing seat is provided with a jaw part under the jaw fixing seat.

[0032] Further, the floating lifting mechanism includes a middle sliding rod 110, and a sliding sleeve 120 that is sleeved outside the middle sliding rod 110 and can slide relative to the middle sliding rod 110, between the outer wall surface of the middle sliding rod 110 and the inner wall surface of the sliding sleeve 120 A sliding part is provided.

[0033] Further, the middle sliding bar 110 is a column structure, with front, rear, left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com