Automatic aired grain recovery machine

A recycling machine and automatic technology, applied in the field of machinery, can solve the problems of difficult to recycle grains, high noise, slow recycling speed, etc., to reduce the probability of rain and get wet, reduce unnecessary losses, and run smoothly and without noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

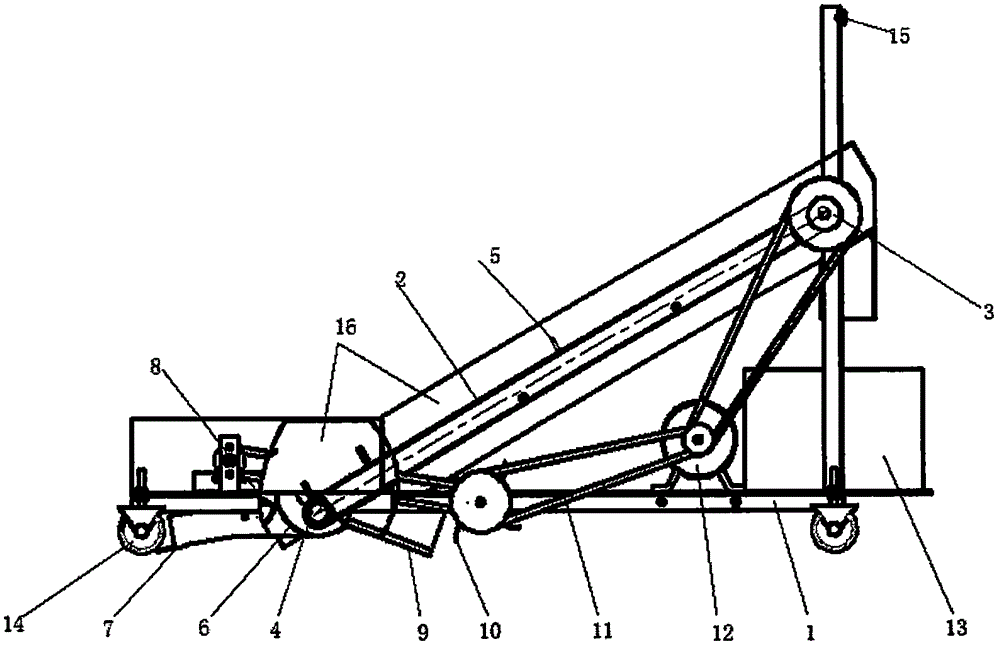

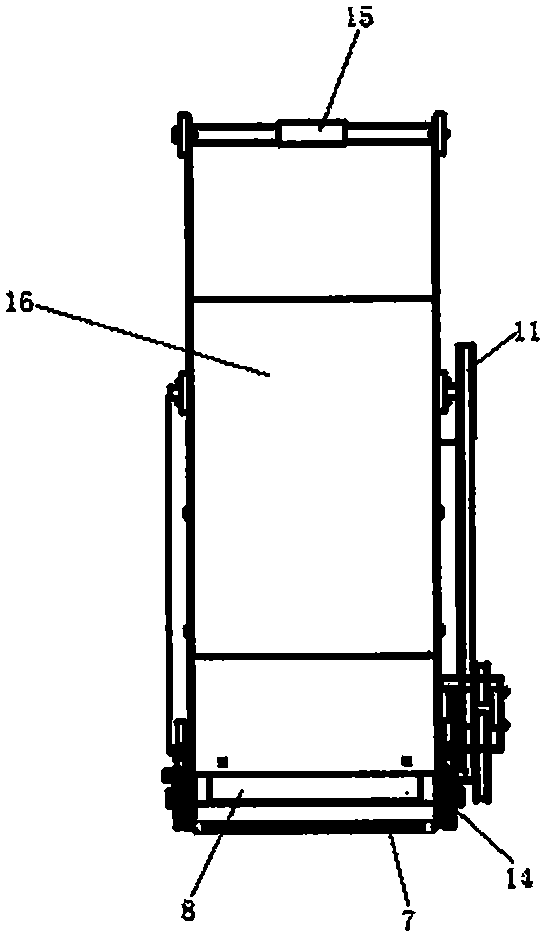

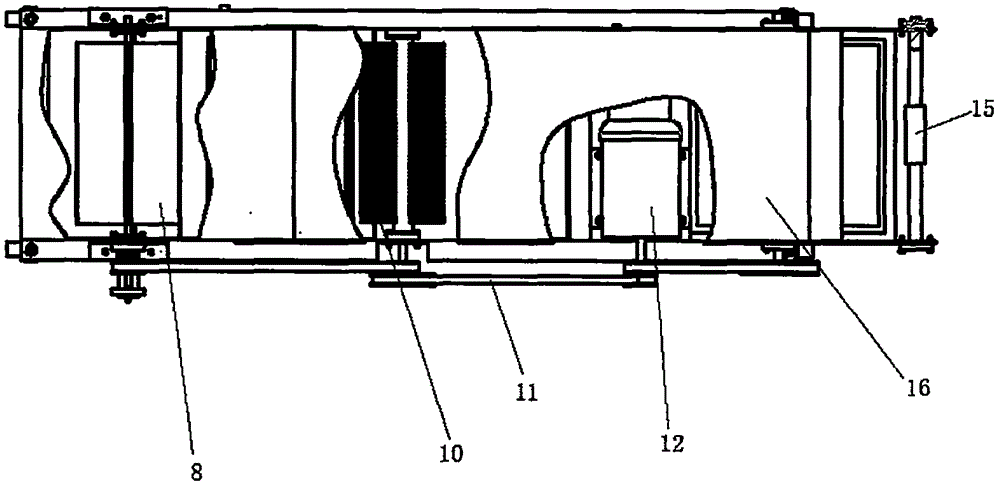

[0015] Such as figure 1 , figure 2 , image 3 As shown, the embodiment of the present invention provides an automatic drying grain recovery machine, the drying grain automatic recovery machine includes: a right-angled tripod 1, the right-angled tripod 1 includes two parallel to the ground brackets and two perpendicular to the ground Support, conveyor belt 2 is installed on described right-angled tripod 1, and described conveyor belt 2 is fixed on described right-angled tripod 1 by driving roller 3 and tail roller 4, and described driving roller 3 is installed on described right-angled tripod 1 On the bracket perpendicular to the ground, the tail roller 4 is installed on the bracket parallel to the ground on the right-angled tripod 1, and a baffle 5 is installed on the conveyor belt 2, and at the tail roller 4 An arc-shaped groove 6 concentric with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com