Wine brewing equipment

An equipment and spherical tank technology, applied in the field of high-efficiency brewing equipment, can solve the problems of long idle time, untimely connection, complicated steps, etc., and achieve the effects of free operation, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

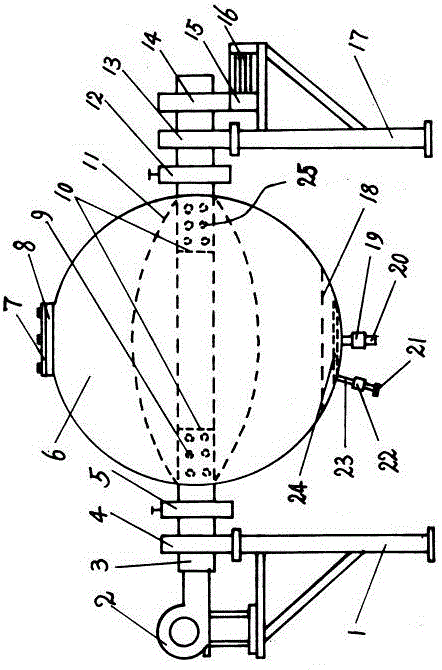

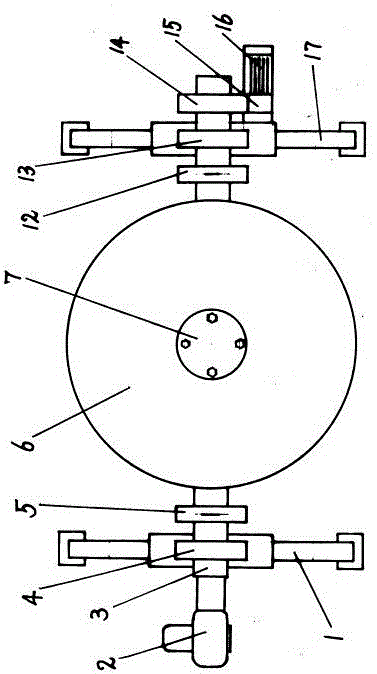

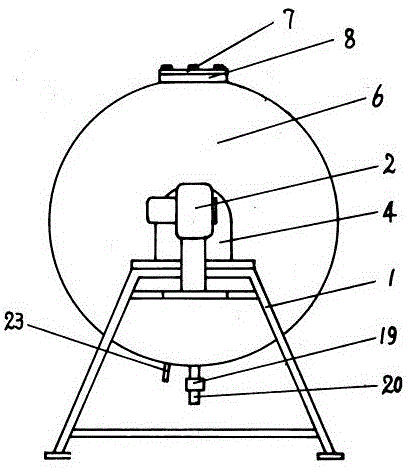

[0024] Such as Figure 1-3 As shown, the spherical tank 6 is a spherical tank body made of steel plates, especially stainless steel plates, and the upper inlet and outlet 8 is a circular or square opening, and the matching cover plate 7 is made of steel plates. And the rubber gasket is fixed and sealed. The hollow shaft 3 is made of the same material as the spherical tank, and is welded as one with the spherical tank. The middle section of the hollow shaft is separated by a partition plate 10, and the partition plate both sides are respectively opened into the air inlet eyelet 9 and the air outlet eyelet 25. The hollow shaft in the spherical tank is surrounded by an ellipsoidal material retaining screen 11 to prevent the material from blocking the wind eye.

[0025] The hollow shaft is divided into three sections, the middle section is welded with the spherical tank as a whole, and the two ends are connected with the left gate valve 5 and the right gate valve 12. Bull gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com