Omnibearing thread scrap filtering unit and washing machine

A filter device, all-round technology, applied in other washing machines, washing devices, textiles and paper making, etc., can solve the problem of not being able to achieve the effect of filtering and collecting lint, directly rebounding and flowing out from the water inlet on this side, and a single lint filtering method, etc. problem, to achieve the effect of simple water intake, lifting effect and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

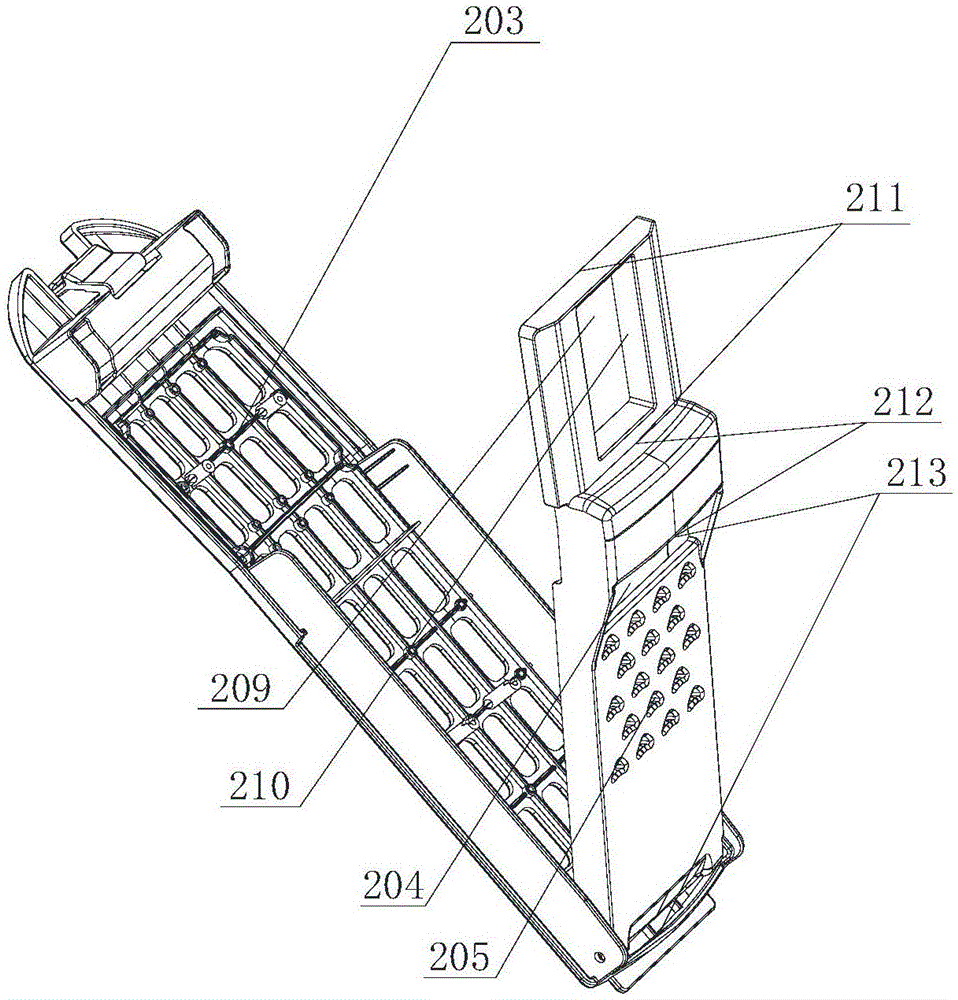

[0066] like image 3 As shown, the difference between this embodiment and the above-mentioned specific implementation is that a backflow prevention structure 205 is arranged on the inner wall of the filter back cover 206 , and the backflow prevention structure 205 is arranged at the lower part of the first water inlet 204 .

[0067] In order to achieve the effect of preventing the backflow of lint by the anti-return structure, and at the same time not to affect the washing water entering the inner cavity of the lint filter for filtering, the anti-return structure 205 is used when the front cover 203 of the filter and the rear cover 206 of the filter are closed. There is a certain distance from the inner wall of the filter front cover 203 . The height of the backflow prevention structure 205 is 1 / 10-1 / 2 of the distance formed after the filter front cover 203 and the filter rear cover 206 are closed, preferably 1 / 4.

[0068] The lower part of the filter front cover 203 and the lo...

Embodiment 2

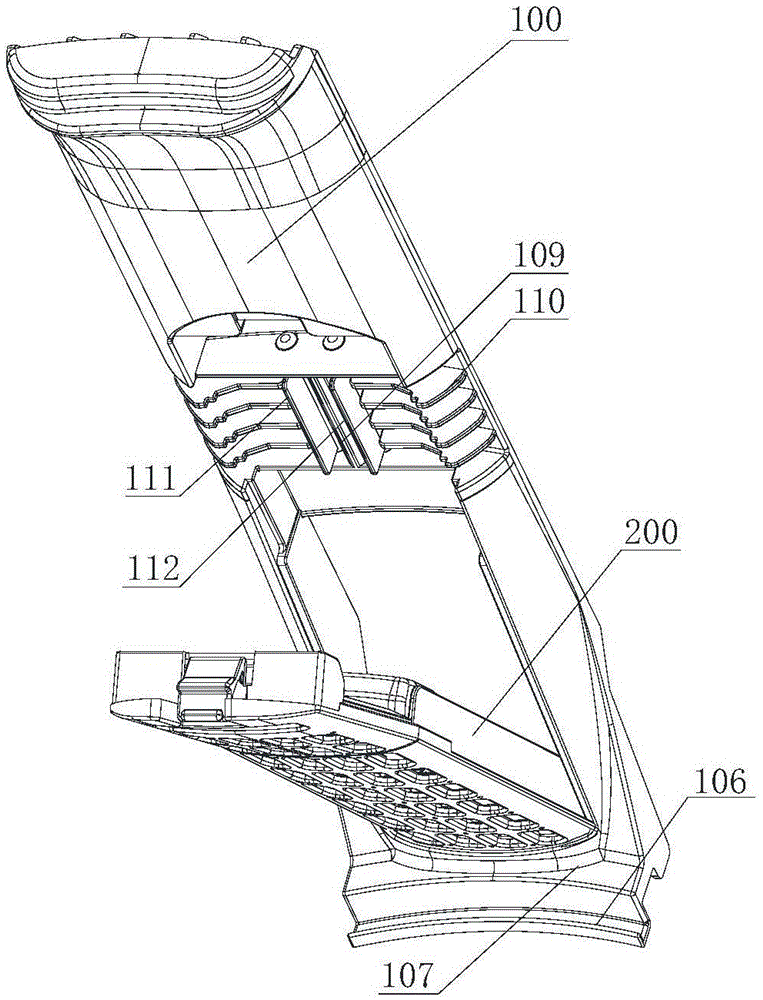

[0072] In the lint filtering device of the above specific embodiment, in order to avoid space for the rotation of the rotating shaft structure, the guide rib 110 generally has a distance of about 0.5mm from the rotating shaft structure, and the guiding rib 110 can only be close to the rotating shaft structure at most. In this way, after the filter 200 is installed on the filter cover 100, the water guide baffle will rotate to the part beyond the guide rib 110 under the drive of the rotating shaft structure, and will be pressed by the filter 200, and it often fails to return smoothly. Phenomenon, which greatly affects the efficiency of lint collection, thereby affecting the use of users.

[0073] like Figure 7 As shown, in order to solve the above problems, this embodiment adopts the following technical solution: the water guide baffle is installed on the filter cover 100 through the rotating shaft structure, and the two sides of the water guide baffle are arranged along the d...

Embodiment 3

[0077] like Figure 8 and Figure 9 As shown, this embodiment provides a washing machine with the lint filtering device described in the above specific embodiments or embodiments, including an inner tub 400 and a pulsator 300 arranged at the bottom of the inner tub 400, and the lint filtering device Installed on the inner side wall of the inner tub 400 , the lower end of the filter cover 100 of the lint filtering device is installed on the bottom side wall of the inner tub 400 .

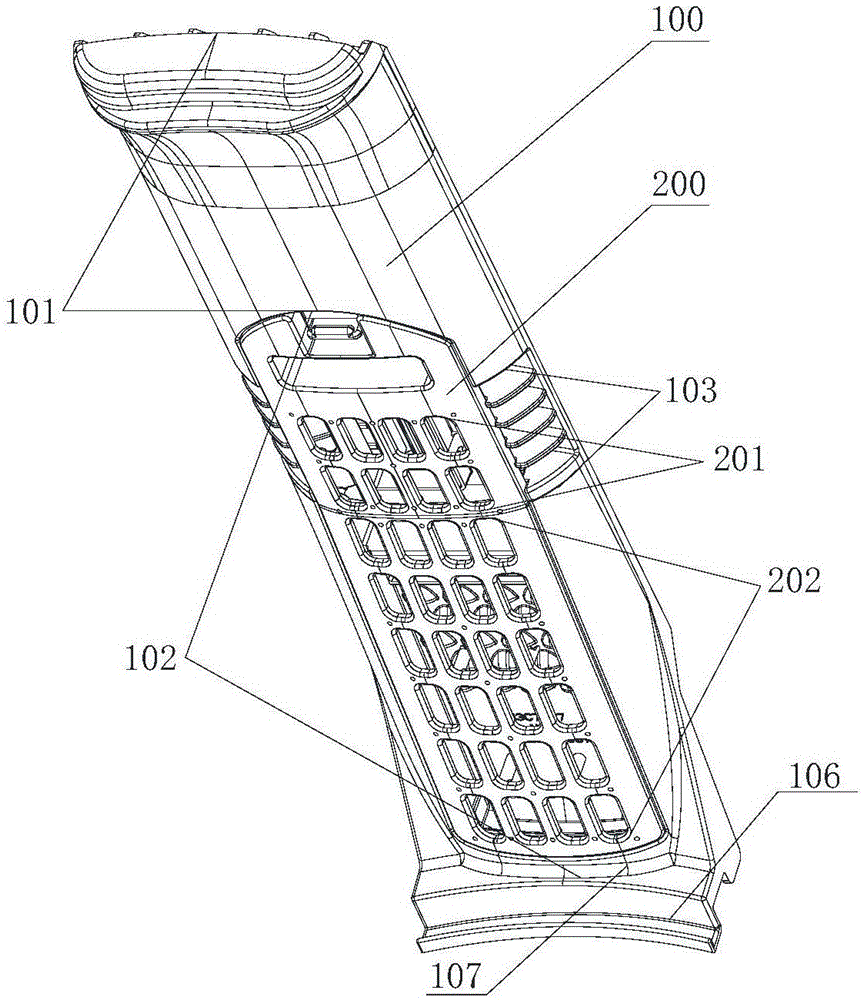

[0078] Specifically, the lower end of the filter cover 100 has a first fixed end 107 and a second fixed end 106, the second fixed end 106 is the lower end of the filter cover 100, and the second fixed end 106 is installed on the bottom side of the inner tub 400 On the wall and in contact with the pulsator 300; the first fixed end 107 is formed by the extension of the filter cover 100 toward the inner side of the inner bucket 400, the first fixed end 107 is arranged on the upper part of the second fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com