Steel sheet pile dewatering well structure

A technology for steel sheet piles and dewatering wells, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of poor precipitation effect, easy collapse, and high cost of dewatering wells, so as to reduce the number of constructions, reduce construction costs, and improve precipitation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

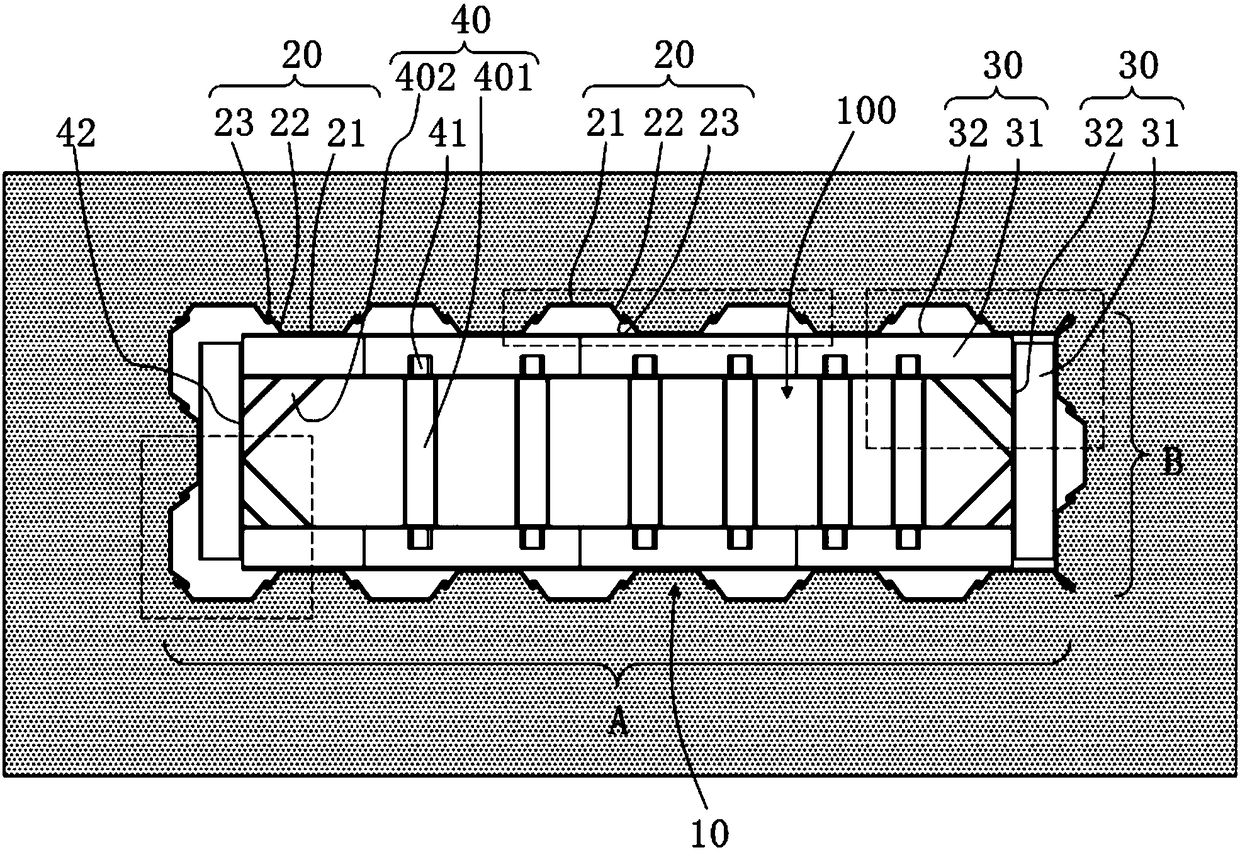

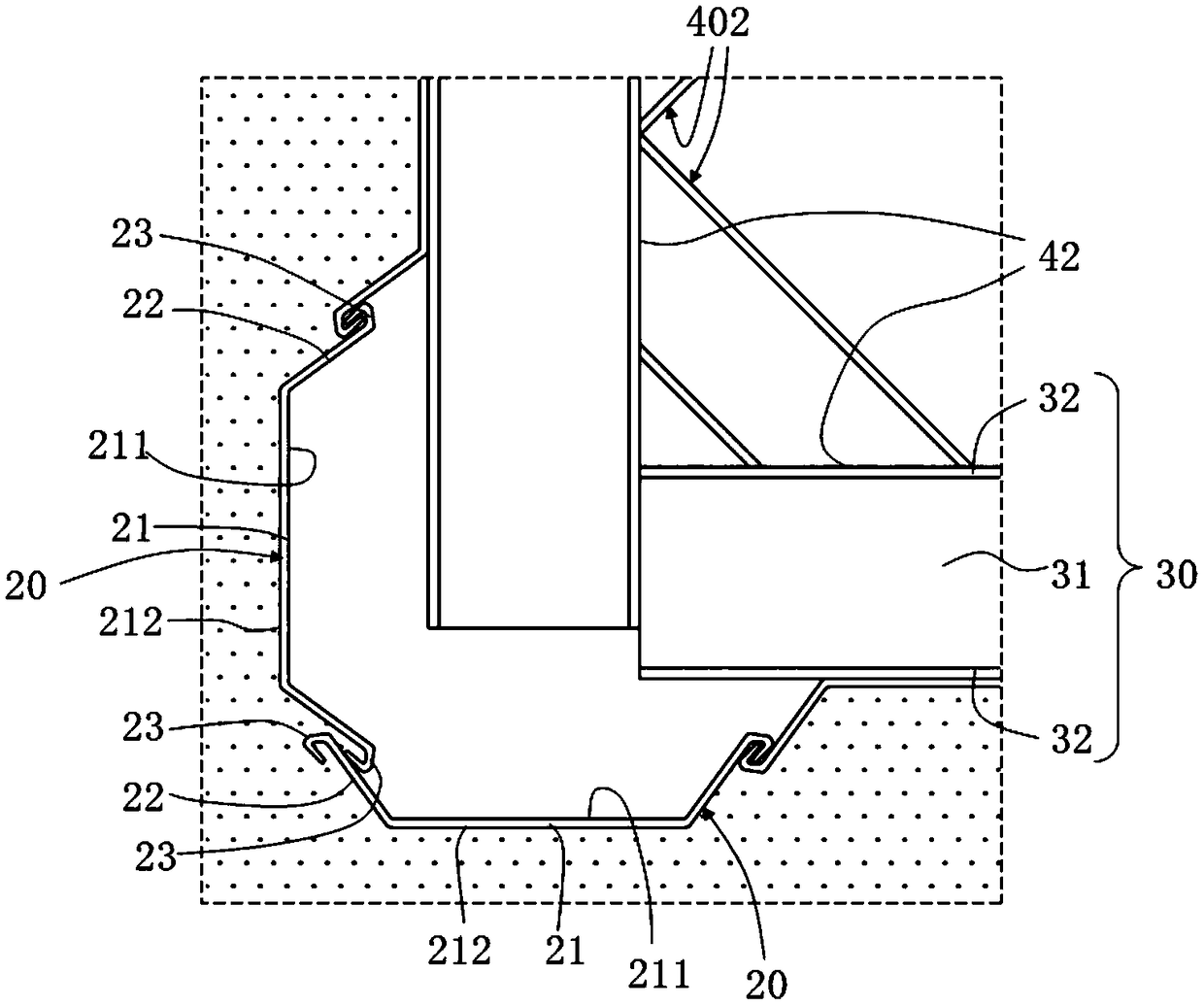

[0032] see Figure 1 to Figure 10 , The present invention provides a combined steel structure dewatering well 100 structure, which is arranged in a foundation pit 10, and the foundation pit 10 has a ground 11, a soil layer 12 and a rock layer 13 in sequence from top to bottom. The present invention is used to penetrate in the soil layer 12 and be arranged on the rock layer 13 .

[0033] The structure of the steel sheet pile dewatering well 100 of the present invention specifically includes a steel sheet pile 20, an H-shaped steel beam 30 and a supporting steel pipe 40; wherein:

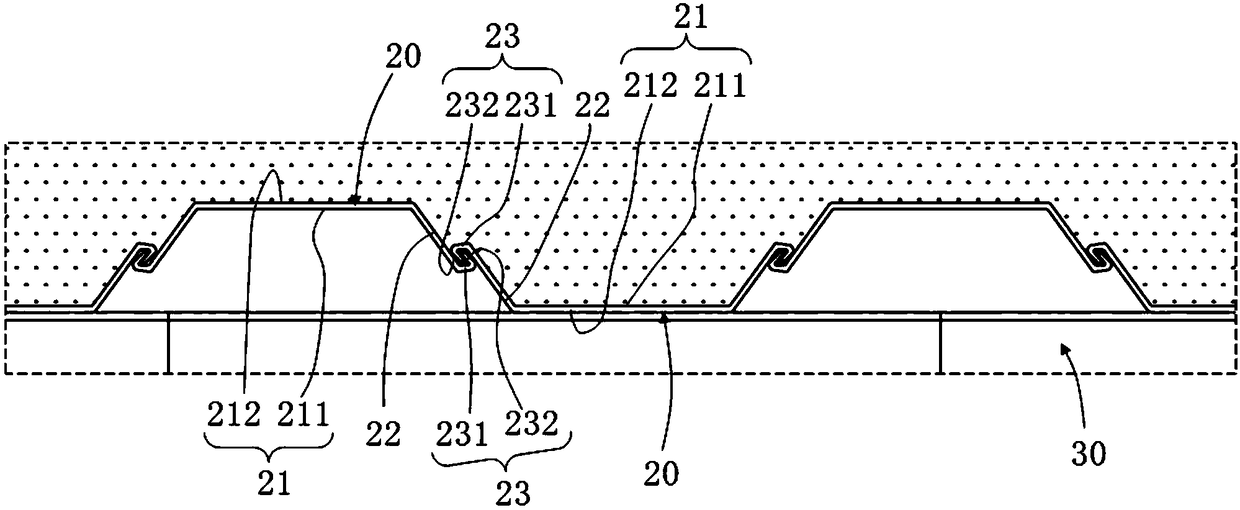

[0034] Such as Figure 5 , Image 6 As shown, the steel sheet pile 20 has a plurality of pieces that can be continuously spliced and arranged on the pit wall of the foundation pit 10; each of the steel sheet piles 20 has a main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com