Rubber damper with presettable stiffness at early stage

A technology of damper and rubber, which is applied in the direction of building components, building structures, and earthquake resistance. It can solve the problems of increasing the volume of the earthquake-resistant structure, poor tensile capacity, inability to stretch, energy consumption, and vibration reduction, and achieve volume reduction, The effect of reducing the cost of seismic isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

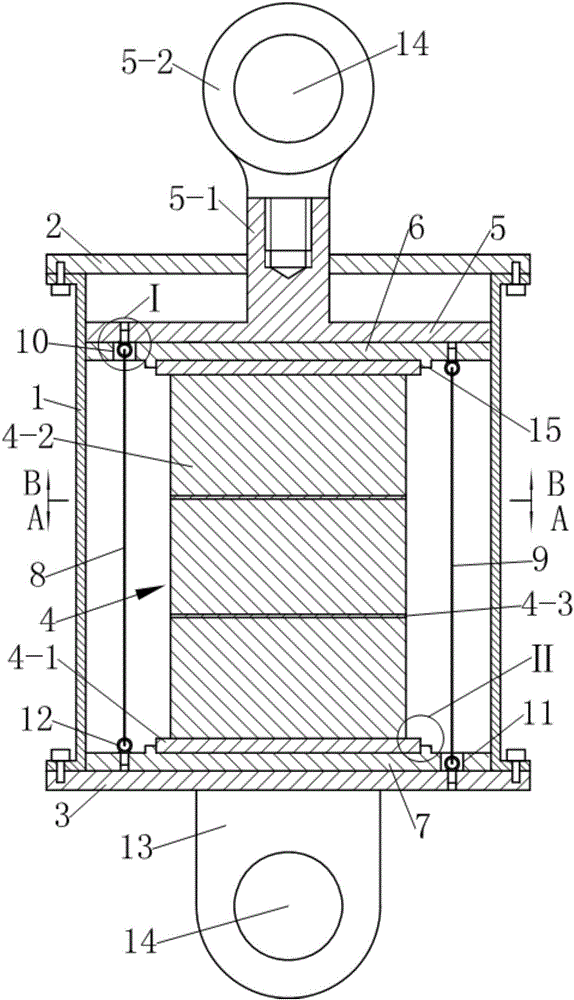

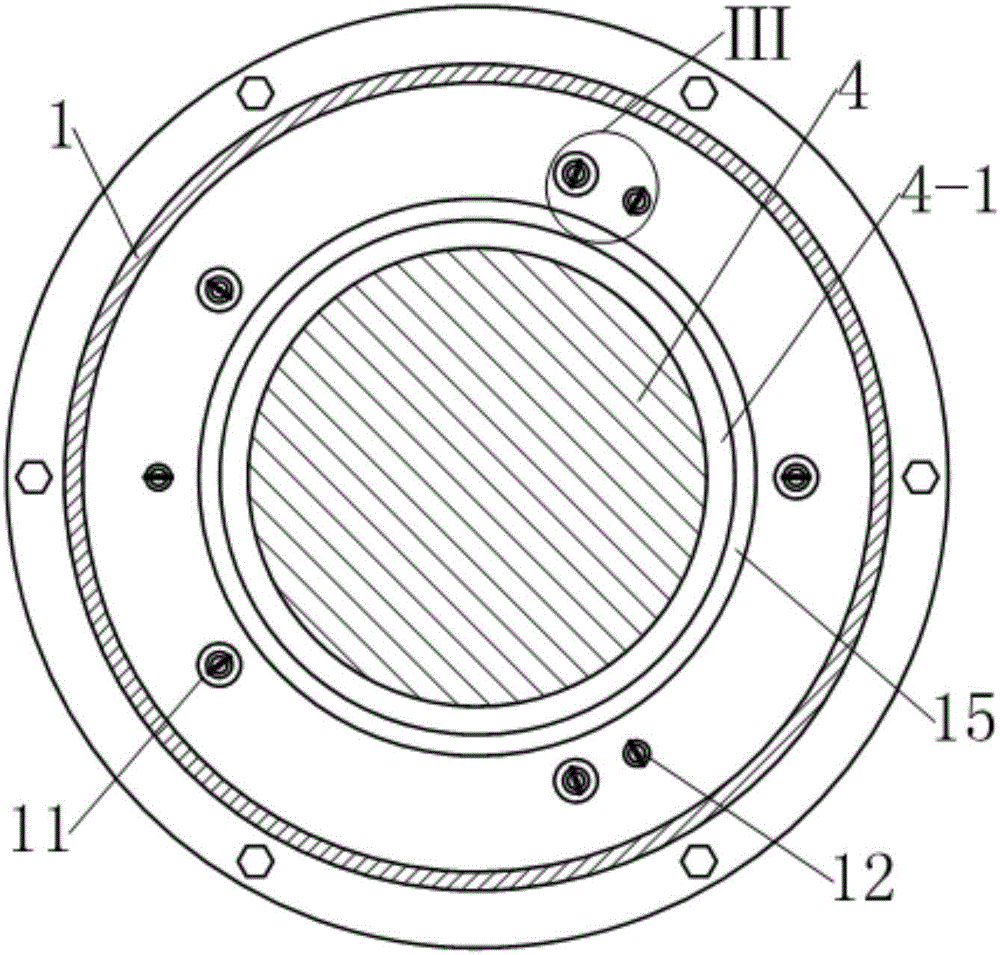

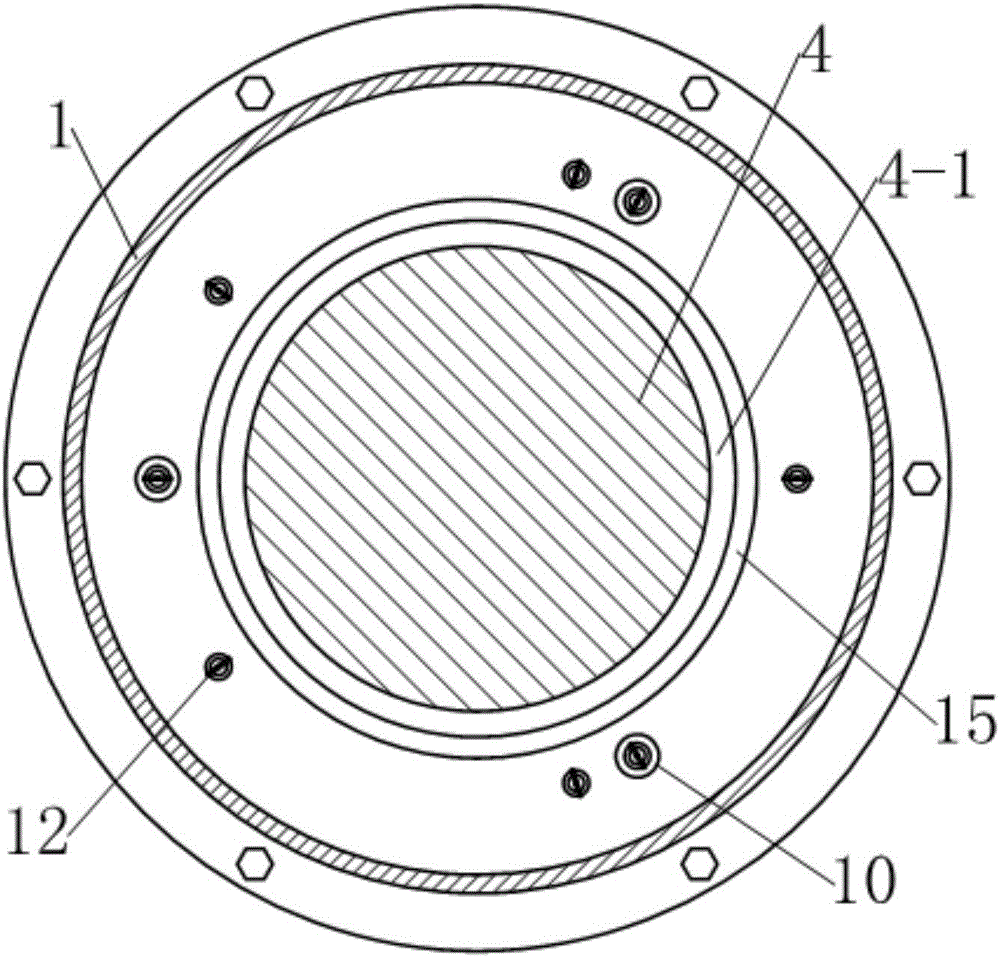

[0039] see figure 1 , the early rubber damper with preset stiffness in this example is an energy dissipation device that can be used for seismic reinforcement of building structures. It includes a guide sleeve 1, a first end cover 2 and a second The end cap 3, wherein, the first end cap 2 and the second end cap 3 are respectively fixedly connected to the two ends of the guide sleeve by screws. A rubber shock-isolating pad 4 is arranged in the axial direction in the guide sleeve 1, and a driving member extends from the center of the first end cover 2 into the guide sleeve 1 and presses on the rubber shock-isolating pad 4; wherein, The driving member is composed of a dynamic pressure plate 5 located at the upper end of the rubber vibration-isolating pad 4 and movingly matched with the guide sleeve 1, and a driving rod 5-1 extending upward from the upper surface of the dynamic pressure plate 5 out of the guide sleeve 1. The driving rod 5 The end of -1 located outside the guide ...

example 2

[0049] This example has the following differences from Example 1:

[0050] see Figure 8-10 , the first group of preloaded steel cables 8 and the second group of preloaded steel cables 9 are composed of three steel cables.

[0051] see Figures 8 to 13 , the upper head of the first group of preloaded steel cables 8 and the lower head of the second group of preloaded steel cables 9 are respectively fixed on the dynamic pressure plate 5 and the second set of steel cables by using cable self-locking anchors 16 instead of the eyebolts in Example 1. On the two end caps 3.

[0052] see Figures 14 to 16 , and combined with Figure 7 , the cable self-locking anchor 16 is composed of a mounting hole provided on the mounting plate 16-1, a jaw 16-2 and a locking bolt 16-4, wherein the mounting plate 16-1 is a movable Pressing plate 5 or second end cap 3 . The axis of the mounting hole is collinear with the straight line where the corresponding pre-compressed steel cable is located...

example 3

[0056] see Figures 17-21 , the rubber damper with preset stiffness in the early stage in this example is a kind of vibration isolation device (also called seismic isolation support) that can be used for vertical seismic isolation of buildings. Compared with Example 2, this example mainly has the following differences:

[0057] 1. As a shock-absorbing support, in order to facilitate installation, in this example, the connecting lug plate provided on the second end cover 3 in Example 2 is omitted, and the second end cover 3 is extended axially downward from the edge and then to the It extends radially outward, and is evenly provided with connecting bolt holes 18 at the edge. The second end cover 3 is used as the base of the shock-isolation support, and the length of the downward axial extension needs to be greater than the self-locking anchor 16 of the steel cable. The length of the part exposed on the outside of the second end cover 3 . The driving rod 5-1 of the driving memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com