Wellhead large-drift diameter continuous ball catcher and control method thereof

A large-diameter, pressure-suppressing ball technology, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the problem that the lateral flange of the gas tree has a small diameter and it is difficult to pass a large-diameter pressure-suppressing ball, reducing The number of catching balls and other issues can be met to meet the requirements of safety production, efficiently recycle pressured balls, and improve the effect of catching balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

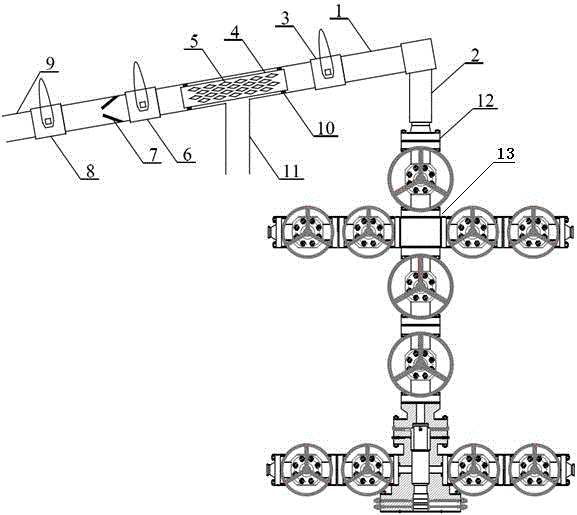

[0034] In order to overcome the existing defects in the existing ball catcher and its method of use, the present embodiment provides a figure 1 The large-diameter continuous ball catcher at the wellhead includes a cylindrical pipe section 1, the right side of which is connected to the wellhead pipeline 2, and the pipe section 1 is inclined 10° to 15° along the vertical direction of the wellhead pipeline 2. A safety cock 3, an isolation cock 6 and a ball collection cock 8 are sequentially arranged on the pipe section 1 from right to left, and a screen pipe 4 is arranged inside the pipe section 1 between the safety cock 3 and the isolation cock 6, The surface of the screen pipe 4 is provided with a plurality of flow holes 5 , the left side of the ball collection cock 8 is connected to the discharge pipeline 9 , and the pipe section 1 in the middle of the screen pipe 4 is connected to the discharge pipeline 11 .

[0035] Wherein, the inner diameter of the screen tube 4 is 85-90 m...

Embodiment 2

[0041] On the basis of Example 1, a spring sheet 7 is provided inside the pipe section 1 between the isolation cock valve 6 and the ball collection cock valve 8, and the spring sheet 7 is mainly used to prevent the pressure-suffocated ball passing through the isolation cock valve 6 from returning Drainage and backflow greatly improve the success rate of catching balls; at the same time, the spring leaf 7 is set on the left downstream of the isolation cock 6, which can be protected by the isolation cock 6 upstream on the right, and is intermittently impacted, prolonging the service life and reducing production costs .

[0042] For the stability and tightness between the screen pipe 4 and the pipe section 1 , the screen pipe 4 and the pipe section 1 are sealed and fixed by a sealing ring 10 .

[0043] The flow hole 5 is diamond-shaped, the distance between the parallel opposite sides of the flow hole 5 is 20-23 mm, and the acute angle between the sides of the rhombus is 40-45°. ...

Embodiment 3

[0045] On the basis of Embodiment 1 and Embodiment 2, this embodiment provides a method for controlling a large-diameter continuous ball catcher at the wellhead, including the following steps:

[0046] 1) Keep the safety cock 3 , the isolation cock 6 and the ball collection cock 8 in the closed state, and connect the wellhead pipeline 2 and the gas tree 13 through the upper flange 12 in the vertical direction.

[0047] 2) Start the blowout process of the gas tree 13, open the safety cock 3, and start the flowback of the pressure holding ball and the flowback fluid in the well.

[0048] 3) After spraying for 15 minutes, open the isolation cock 6 for 5 seconds, then close the isolation cock 6 again.

[0049] 4) Open the ball collection cock 8, and recover the pressure-suppressing balls discharged from the discharge line 9.

[0050] 5) Repeat steps 3) and 4) until all the pressure-suppressing balls in the well are recovered.

[0051] In the present invention, the wellhead pipel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com