Integral steam distribution apparatus for layered sand-prevention well

A technology for gas distribution and sand control, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc. It can solve the problems of uneven production of oil layers, not finding the same technology, affecting development effects, etc., achieving large space, testing and deployment Convenient, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

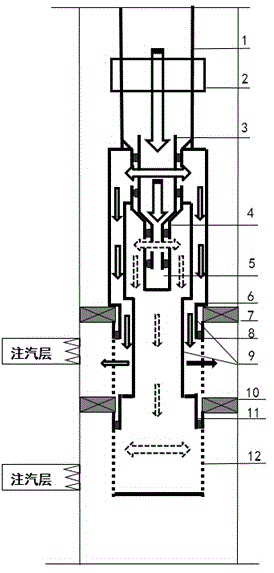

[0029] according to Figure 1-5 , an integrated steam distribution device for layered sand control wells, namely figure 1 , consists of heat insulation tube 1, compensator 2, dispensing core 3 and dispensing device 4, double-pipe sealing 9, single-pipe sealing pipe 11 and so on.

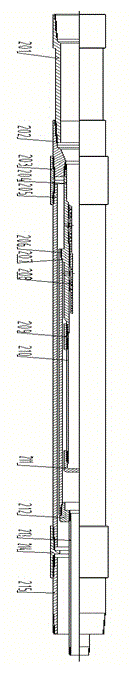

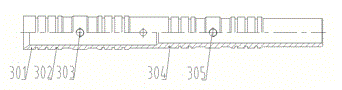

[0030] figure 2 The integrated steam distributor is mainly composed of lifting nipple 201, upper joint 202, tubing nipple 210, tubing coupling 209, outer pipe 205, casing coupling 203, liner 206, distribution central pipe 204, etc.; The internal threaded connection of the device has image 3 Dispenser core, the lower part of the steam distributor is connected with Figure 4 Double tube insertion and Figure 5 The single-tube plug seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com