Cut-through excavating construction method for large-cavern-diameter and small-cavern-diameter underground caverns

A technology for underground caverns and construction methods, applied in underground caverns, earthwork drilling, blasting, etc., can solve the problems of poor molding quality of cavern openings, difficulty in controlling blasting vibration and loose rock circles, and achieve blasting construction molding quality Good, construction safety guaranteed, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the examples.

[0033] Those skilled in the art will understand that the following examples are only for illustrating the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the documents and specifications in this field or according to the product specification. The materials or instruments used are not indicated by the manufacturer, and they are all conventional products that can be obtained through purchase.

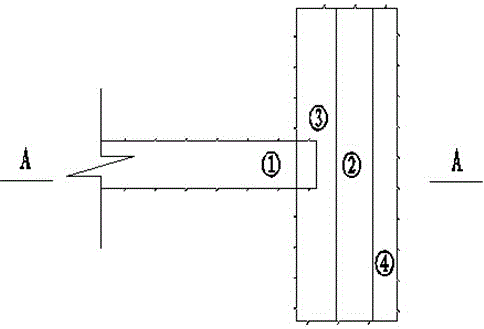

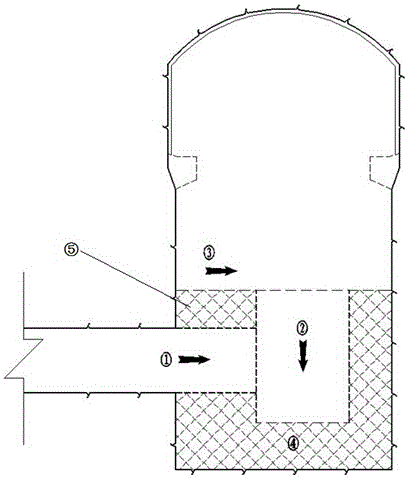

[0034] like Figure 1~2 As shown, a construction method for excavating underground caverns with large and small diameters, the steps are as follows:

[0035] The small-diameter caverns are excavated ahead of time to the large-diameter caverns. When over-excavating to the large-diameter cavern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com