Tunnel back break control system based on folding propelling beam structure

A technology of control system and propelling beam, which is applied in tunnels, drilling equipment, drilling equipment and methods, etc., can solve the problems of difficult control of the bending angle of the drill pipe, over and under excavation, etc., and achieves easy popularization and application, reasonable structure design, Good pass performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

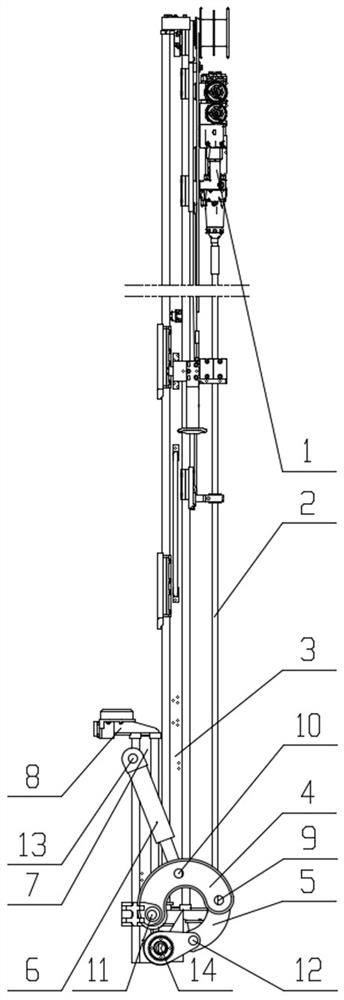

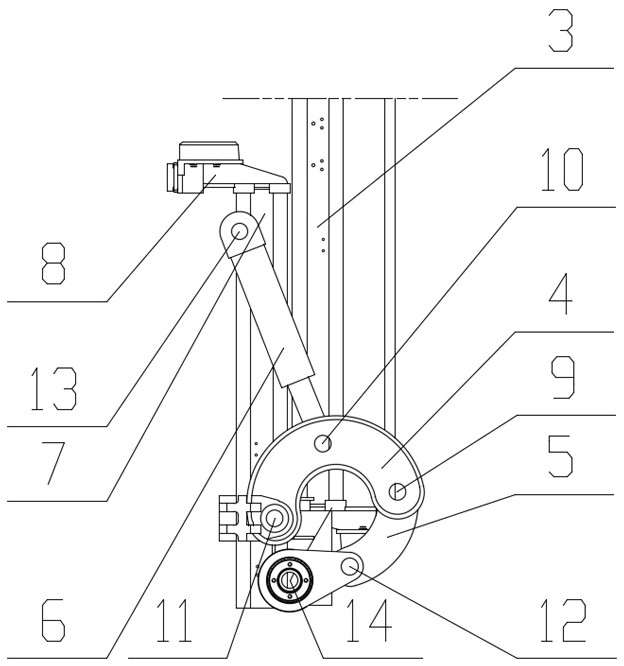

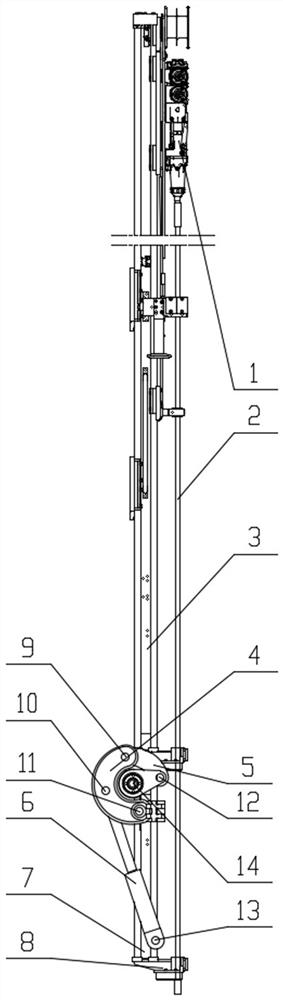

[0027] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0028] Such as Figure 1~Figure 5 As shown, the tunnel overbreak and underbreak control system based on the folded propulsion beam structure includes a propulsion beam main beam 3, a rock drill 1 and a drill pipe 2, the rock drill 1 is slipped on the propulsion beam main beam 3, and the rock drill 1 drives the drill The rod 2 is moved to drill the face of the face. The head of the propulsion beam main beam 3 is provided with a drill supporter 1, the drill rod 2 passes through the drill supporter 1, and the drill rod 2 is distributed parallel to the propulsion beam main beam 3 .

[0029] In order to realize the flexible adjustment of the position of the drill pipe 2, the head of the main beam 3 of the advancing beam is hinged with a folded beam 7. Specifically, the head of the main beam 3 of the advancing beam is hinged with the tail of the folded be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com