Roadway advanced support control system and numbering method

A technology of advanced support and control system, applied in earth square drilling, mine roof support, mining equipment, etc., can solve the problems of increased system hardware cost, no public coding method, insufficient safety and efficiency of roadway excavation, etc. Reach the effect of reducing hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

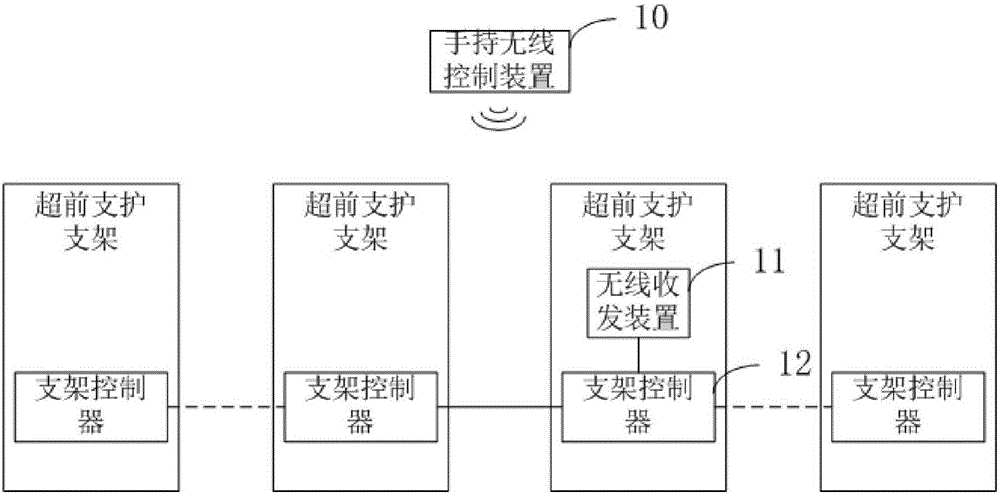

[0023] This embodiment provides a technical solution of the roadway advance support control system. In this technical solution, the roadway advance support control system includes: a wireless transceiver device 11 arranged on an advance support support and maintaining a communication connection with the support controller on the support; The rack controller 12 on the rack.

[0024] The wireless transceiver device 11 is arranged on one of the multiple advanced support supports. Wireless signal interaction can be performed between the wireless transceiver device 11 and the handheld wireless control device 10 held by the user. The handheld wireless control device 10 is also called a "remote controller". By operating the handheld wireless control device 10, the user can send control instructions for the entire roadway advance support system to the wireless transceiver device 11.

[0025] In addition, one of the plurality of rack controllers 12 of the wireless transceiver device ...

no. 2 example

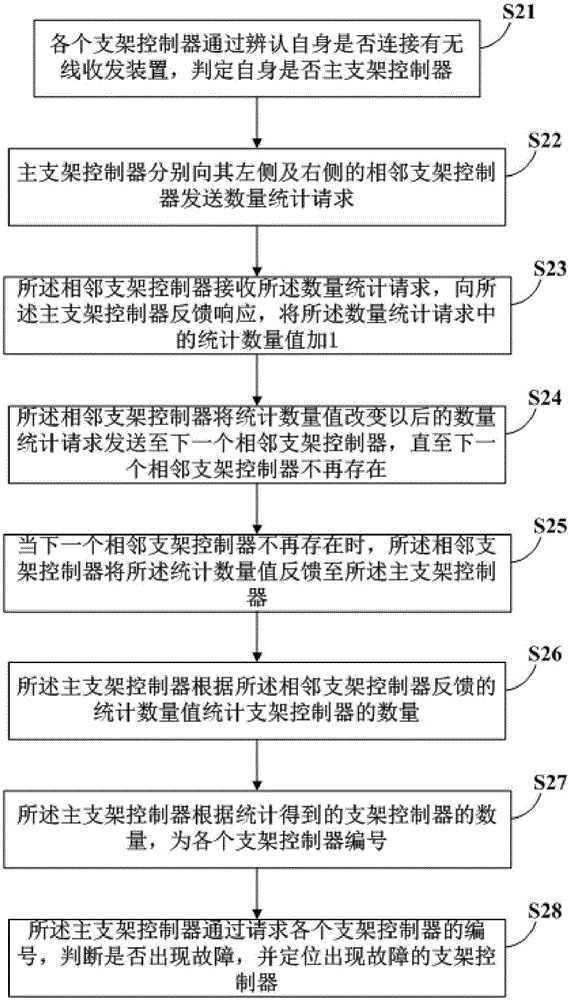

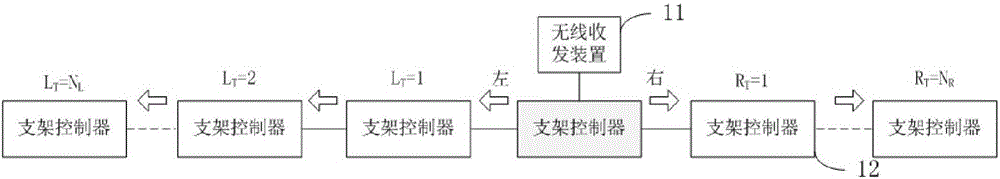

[0035] This embodiment provides a technical solution for the numbering method of the roadway advance support control system. In this technical solution, the numbering method of the roadway advance support control system includes: the main support controller sends quantity statistics requests to the adjacent support controllers on the left and right sides respectively, wherein the main support controller sends The statistical quantity value contained in the quantity statistics request is 0; the adjacent support controller receives the quantity statistics request, feeds back a response to the main support controller, and adds 1 to the statistical quantity value in the quantity statistics request ; The adjacent rack controller sends the quantity statistics request after the statistical value changes to the next adjacent rack controller until the next adjacent rack controller no longer exists; when the next adjacent rack controller no longer exists , the adjacent rack controller f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com