Lens, light emitting device and backlight module

A light-emitting device and lens technology, applied in the field of optics, can solve the problems of uneven lighting and over-brightness of backlight modules, and achieve the effect of increasing lighting uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

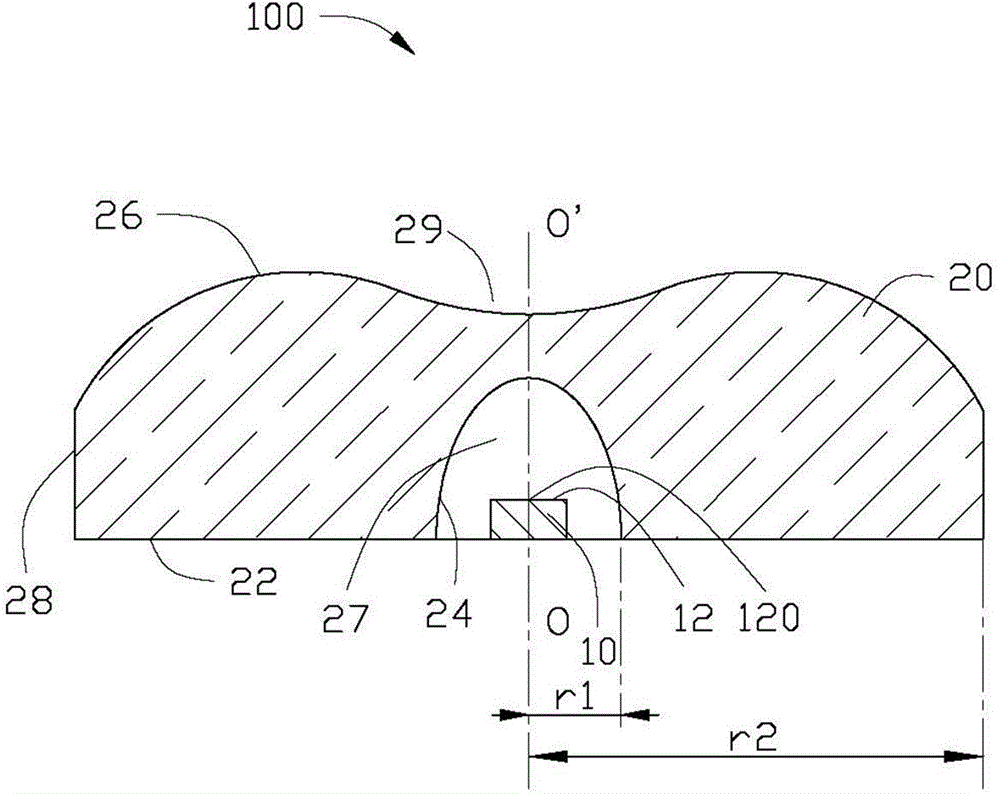

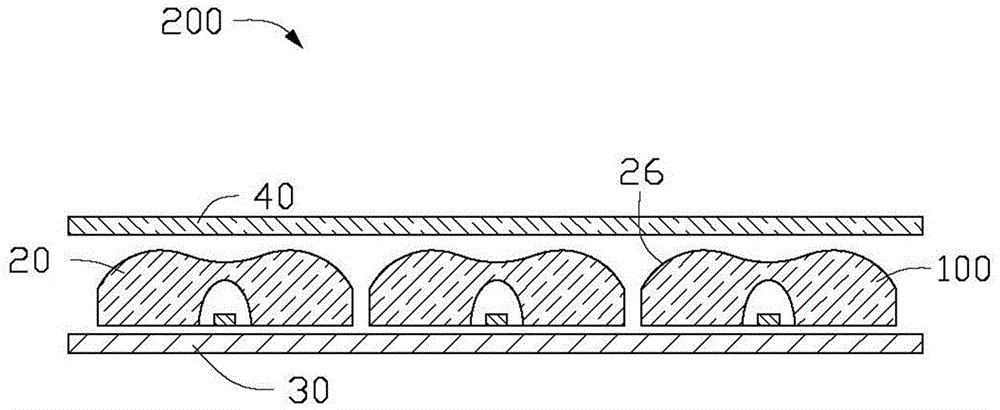

[0015] see figure 1 , the light emitting device 100 provided by the first embodiment of the present invention includes a light emitting unit 10 and a lens 20 . The lens 20 is located directly above the light emitting unit 10 and is used for controlling the light emitted by the light emitting unit 10 .

[0016] In this embodiment, the light emitting unit 10 is an LED that emits light toward the lens 20 . The light emitting unit 10 includes a light emitting surface 12 facing the lens 20 . The light emitting surface 12 has a center point 120 located in the center and a center axis OO' perpendicularly passing through the center point 120.

[0017] The lens 20 can be made of transparent material, such as plastic or glass. The plastic can be PMMA (polymethyl methacrylate), PC (polycarbonate, polycarbonate), or silicone. The lens 20 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com