Electric boiler of blow-molding water tank with semiconductor or optical energy heating and decompression function

A semiconductor and electric boiler technology, applied in the field of electric boilers, can solve the problems of explosion, water leakage, short life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

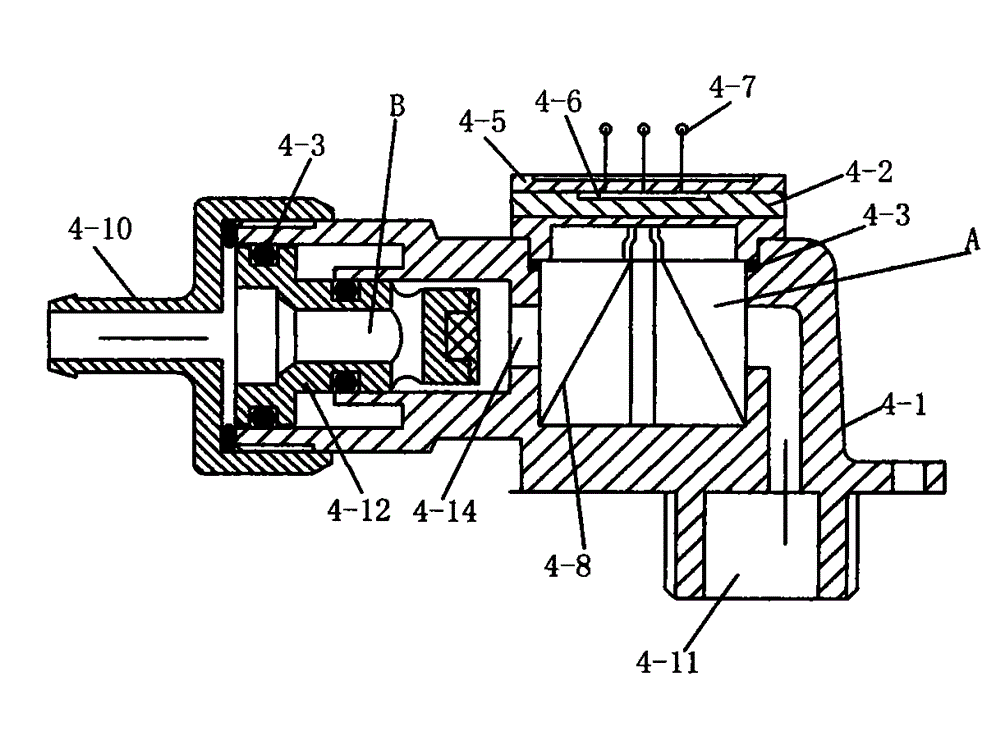

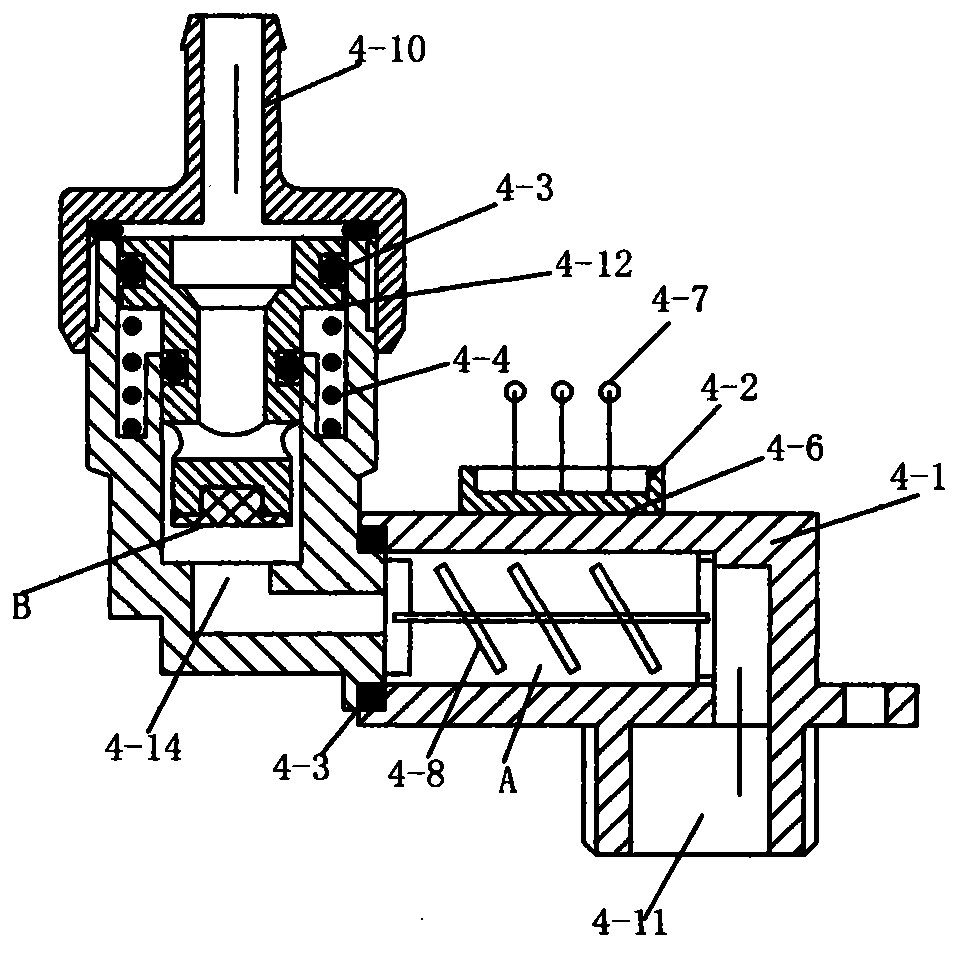

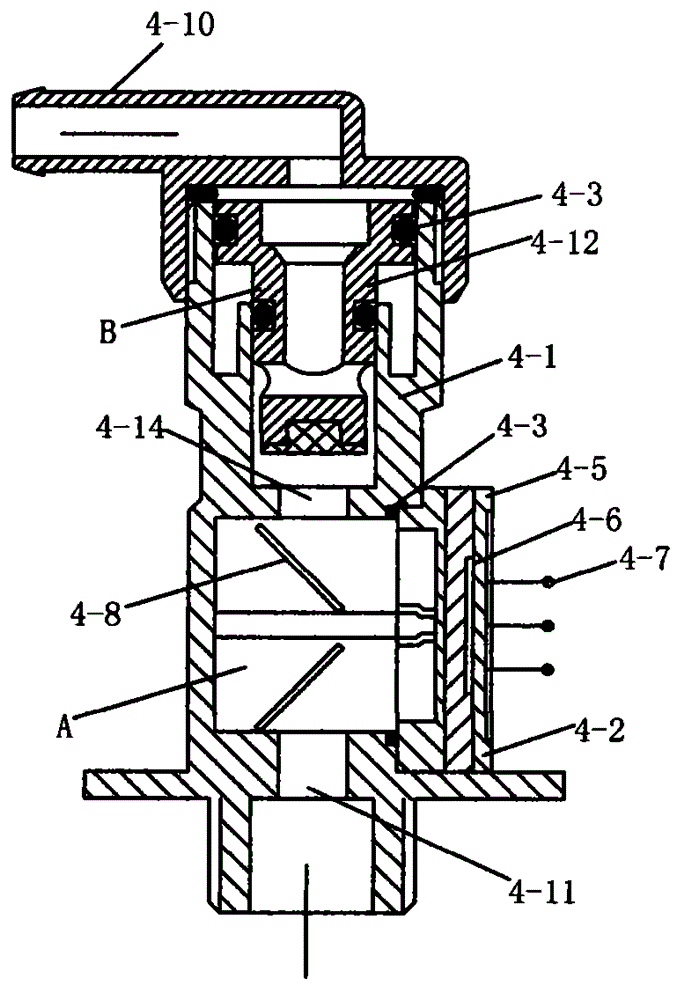

[0019] Attached below Figures 1 to 16 In the accompanying drawings: shell 1, cold water inlet pipe 2, hot water outlet pipe 3, water flow sensor or water flow switch 4 with decompression function, controller 5, electric heating tube 6 (semiconductor or light energy heating electric heating Pipe 6-1, metal electric heating pipe 6-2), outlet pipe fixed fulcrum 7, water tank 8, faucet 9, temperature measurement or temperature limit switch installation pipe 10, flange 11, pressure relief valve 14, sewage outlet 15, water flow Outdated water heating device 16 (closed type 16-1; semi-open type 16-2), metal or non-metallic casing 17, air 18, water 19, return pipe 20, living room floor heating 21, radiator heating 22, domestic hot water 23. Circulation pump 24.

[0020] Figure 1 to Figure 3 It is a structure diagram of a water flow sensor with a decompression function, Figure 4 Figure 8 is a water flow switch with decompression function. The common feature is that it can automati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com