Supercooled water dynamic ice slurry preparing system

A dynamic ice slurry and manufacturing system technology, which is applied in ice making, ice making, lighting and heating equipment, etc., can solve the problems of low evaporation temperature of the refrigeration host, low energy efficiency ratio, and increased energy consumption of water pumps, so as to reduce energy consumption, The effect of saving cost and reducing the temperature difference of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

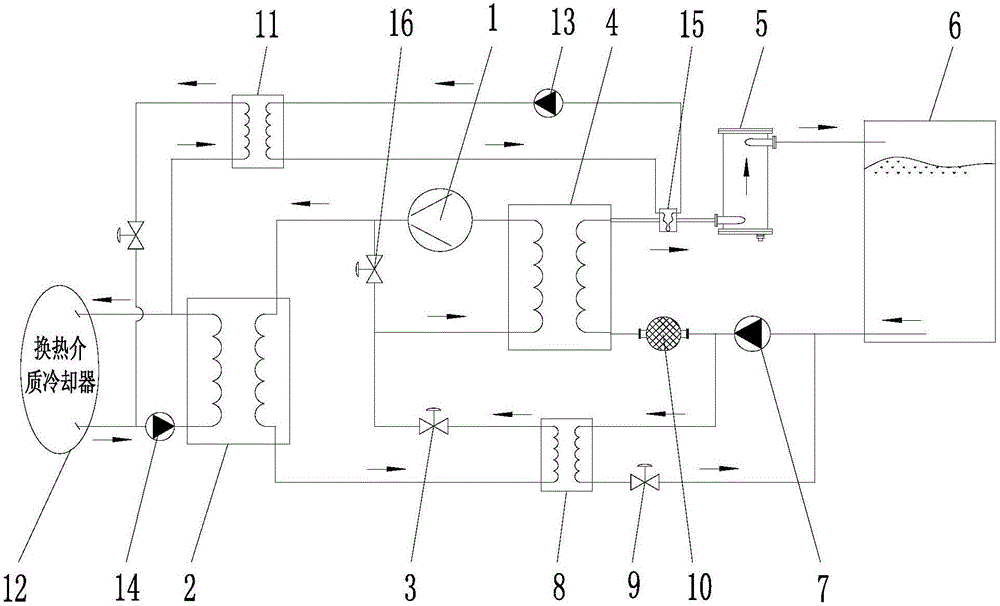

[0023] A supercooled water dynamic ice slurry manufacturing system, including a compressor 1, a condenser 2, a throttle valve 3, a supercooled water plate heat exchanger 4, a crystal accelerator 5, an ice storage tank 6, and a water pump 7, a compressor, a condenser The hot side channel of the supercooled water plate heat exchanger, the throttle valve and the cold side channel of the supercooled water plate heat exchanger are connected end to end in order to form a refrigeration system. The hot side channel inlet of the supercooled water plate heat The outlet of the hot side channel of the heater is connected with the input port of the crystal accelerator through the delivery pipe, the ice storage tank is connected with the output port of the crystal accelerator, and the water inlet of the water pump is connected with the ice storage tank through the water inlet pipe.

[0024] Preferably, it also includes an anti-blocking circulation loop, the anti-blocking circulation loop inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com