Dual-camera measuring method for accurate calibration of distance between optical identification points

A measurement method and technology for identifying points, applied in the field of optical measurement, can solve the problems of the influence of the accuracy of the reference ruler, the inability to guarantee the parallelism of the reference ruler and the guide rail, etc. It is simple and easy to implement, easy to measure and verify multiple times, and simple and convenient to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The description will be further described below in conjunction with the embodiments and the accompanying drawings.

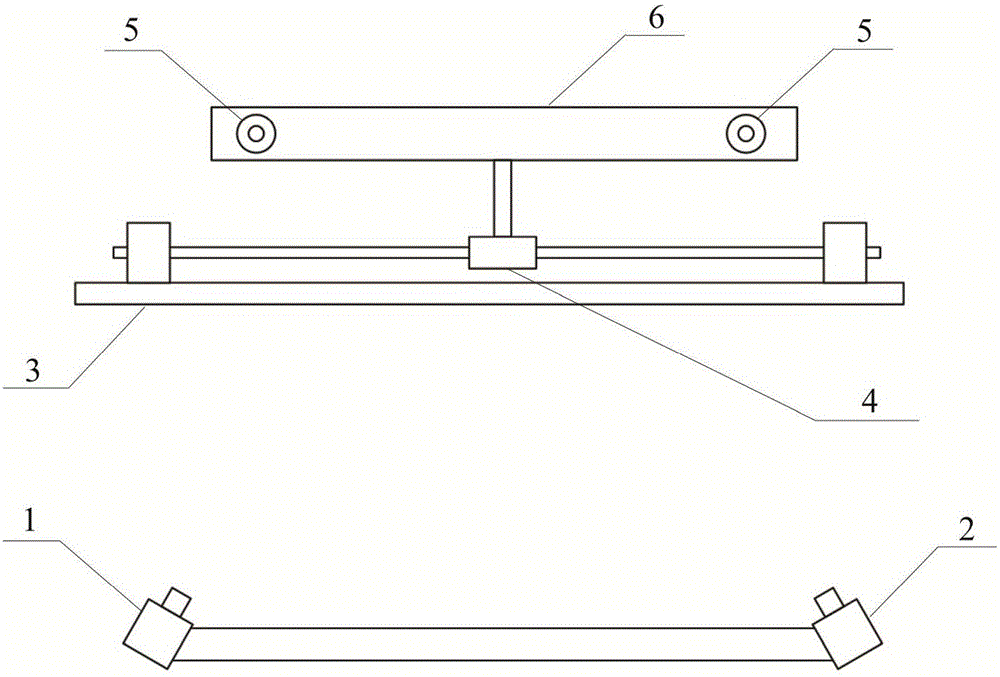

[0023] Build a binocular stereo vision system, fix two industrial cameras on an optical anti-vibration platform, determine the field of view and spacing of the cameras according to the distance between the optical marking points to be measured, and make the angle between the two cameras about 25°, place the The single-axis electric displacement platform is placed on the plane where the optical marking point to be measured is located.

[0024] The dual-camera measurement method for distance calibration between optical marking points includes the following steps:

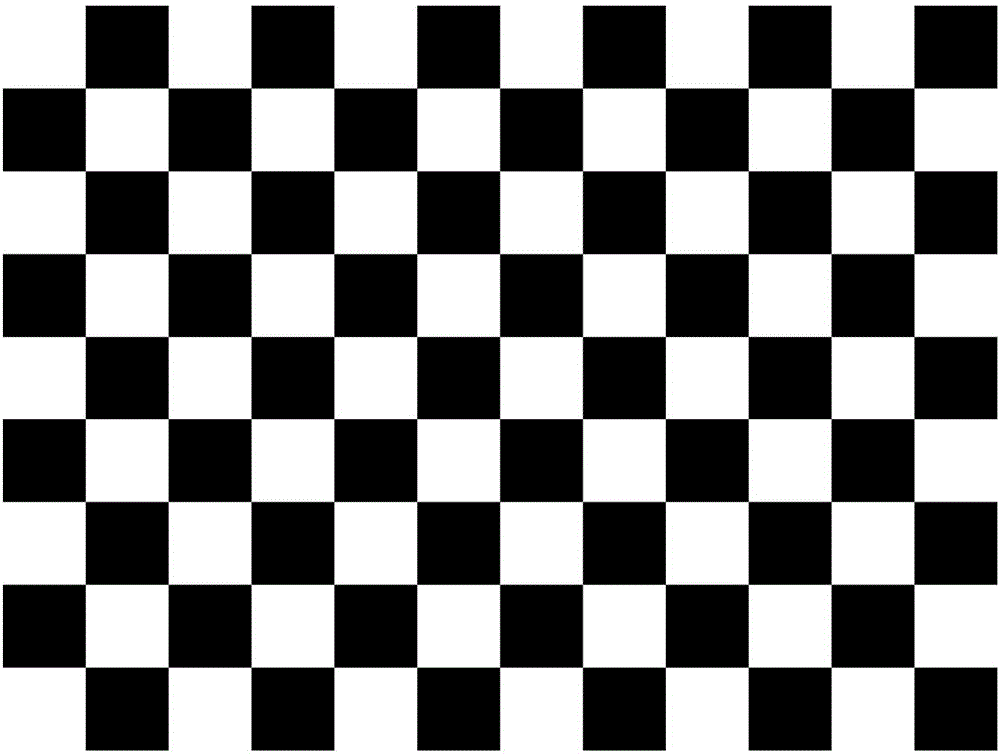

[0025] 1) Initial calibration of the binocular stereo vision system: the figure 1 The checkerboard calibration board shown is placed on the plane where the optical marking points are located, and the mobile workstation is used to control the two cameras to collect the images of the calibration b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com