Water seepage fault detection method and device of steel structure building and wallboard junction box

A fault detection, junction box technology, applied in measuring devices, liquid/vacuum measurement for liquid tightness, instruments, etc., can solve problems such as corrosion of internal pipelines, electrical fires, exposure to water vapor or rainwater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

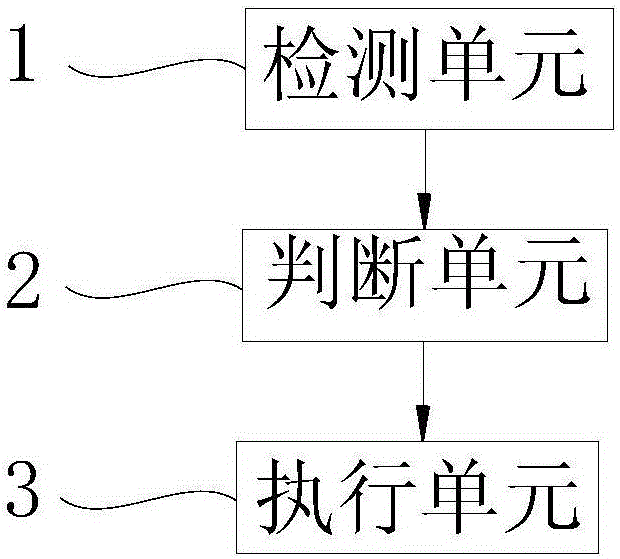

[0031] The core of the present invention is to provide a water seepage fault detection method for the junction box of the wall board of the steel structure building, so that when a water seepage fault occurs in the junction box, corresponding measures can be taken in time to remind the user to repair and maintain in time to avoid fire danger, improve home safety. Another core of the present invention is to provide a water seepage fault detection device based on the above water seepage fault detection method, and a steel structure building including the water seepage fault detection device.

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

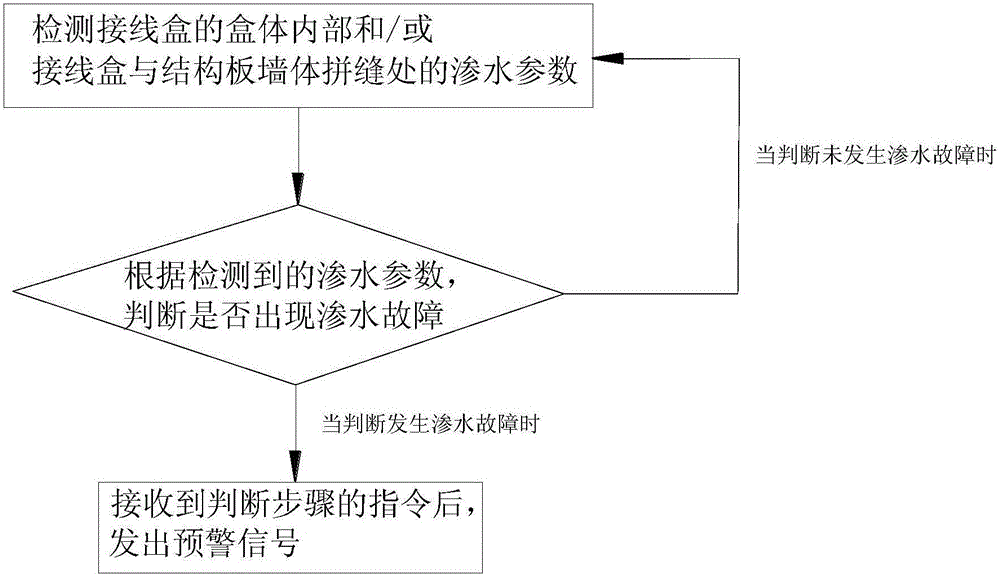

[0033] Please refer to figure 1 , figure 1 It is a flow chart of a specific embodiment of the water seepage fault detection method provided by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com