Method for Measuring Elastic Modulus of Pipe Coating

An elastic modulus, measuring tube technology, which is used in the preparation of test samples, the use of stable tension/pressure to test the strength of materials, etc. Coating elastic modulus, can not be measured and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

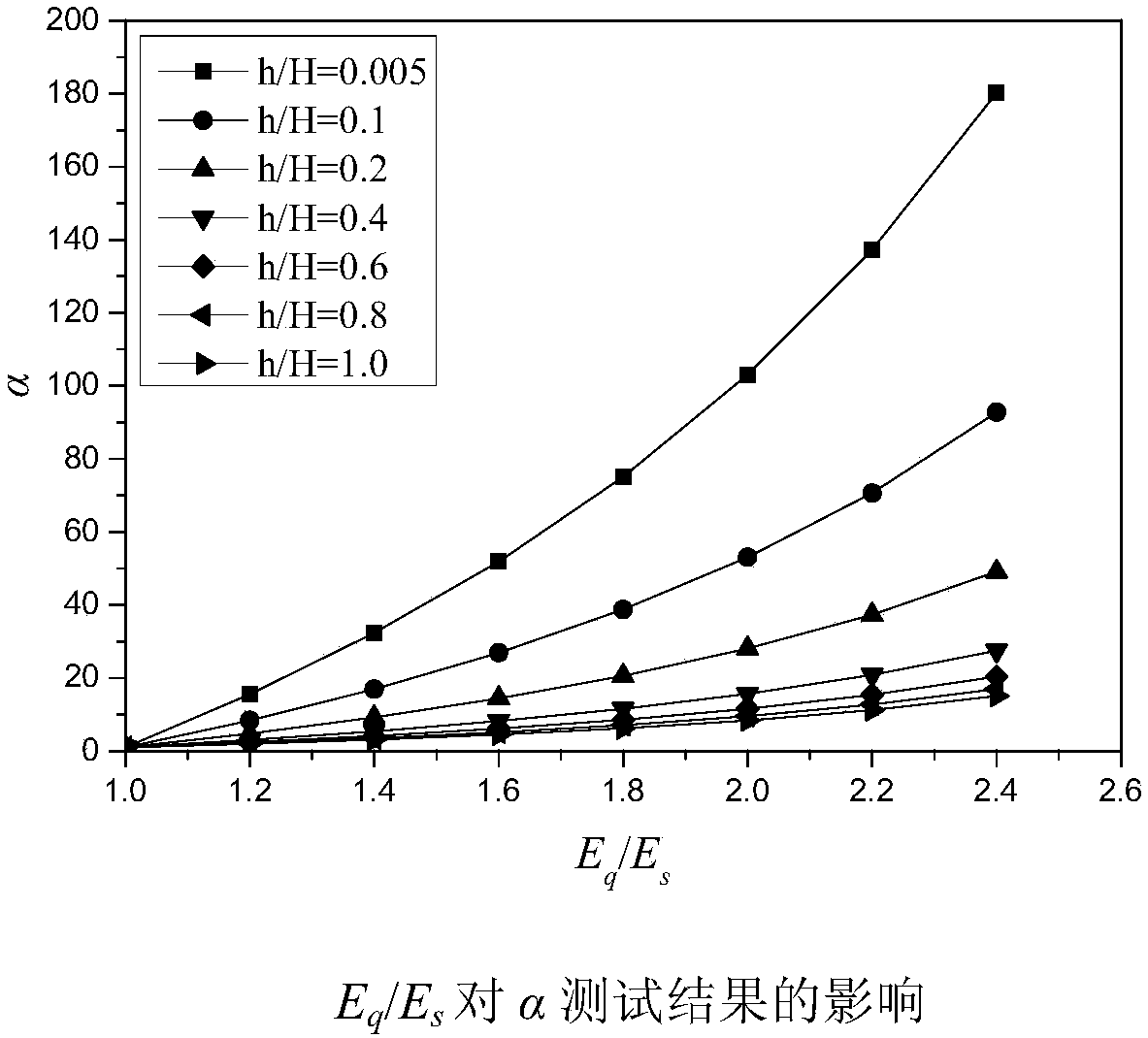

[0090] Embodiment 1: Measurement of elastic modulus of outer coating

[0091] On the basis of obtaining the elastic modulus of the matrix above, the following steps are also included:

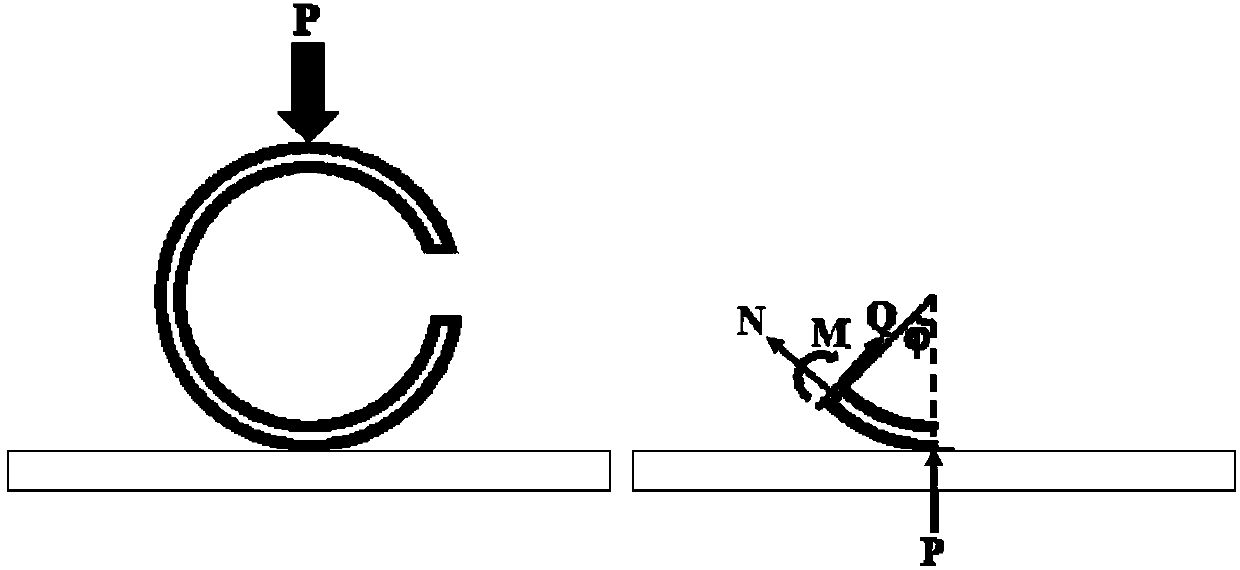

[0092] 1) Remove the inner surface of C-SiC and the upper and lower ends of the coating by grinding to obtain the outer coating of the C-SiC pipe coating sample, and then use a diamond blade to cut a gap with a width of about 2 mm to form a gap ring sample;

[0093] 2) Use a micrometer to measure the outer diameter R of the notched ring sample c = 15.10mm, inner diameter r = 11.95mm, width b = 7.16mm; using a digital microscope to measure the coating thickness h = 36μm; then the outer diameter of the substrate R = Rc-h = 15.064mm;

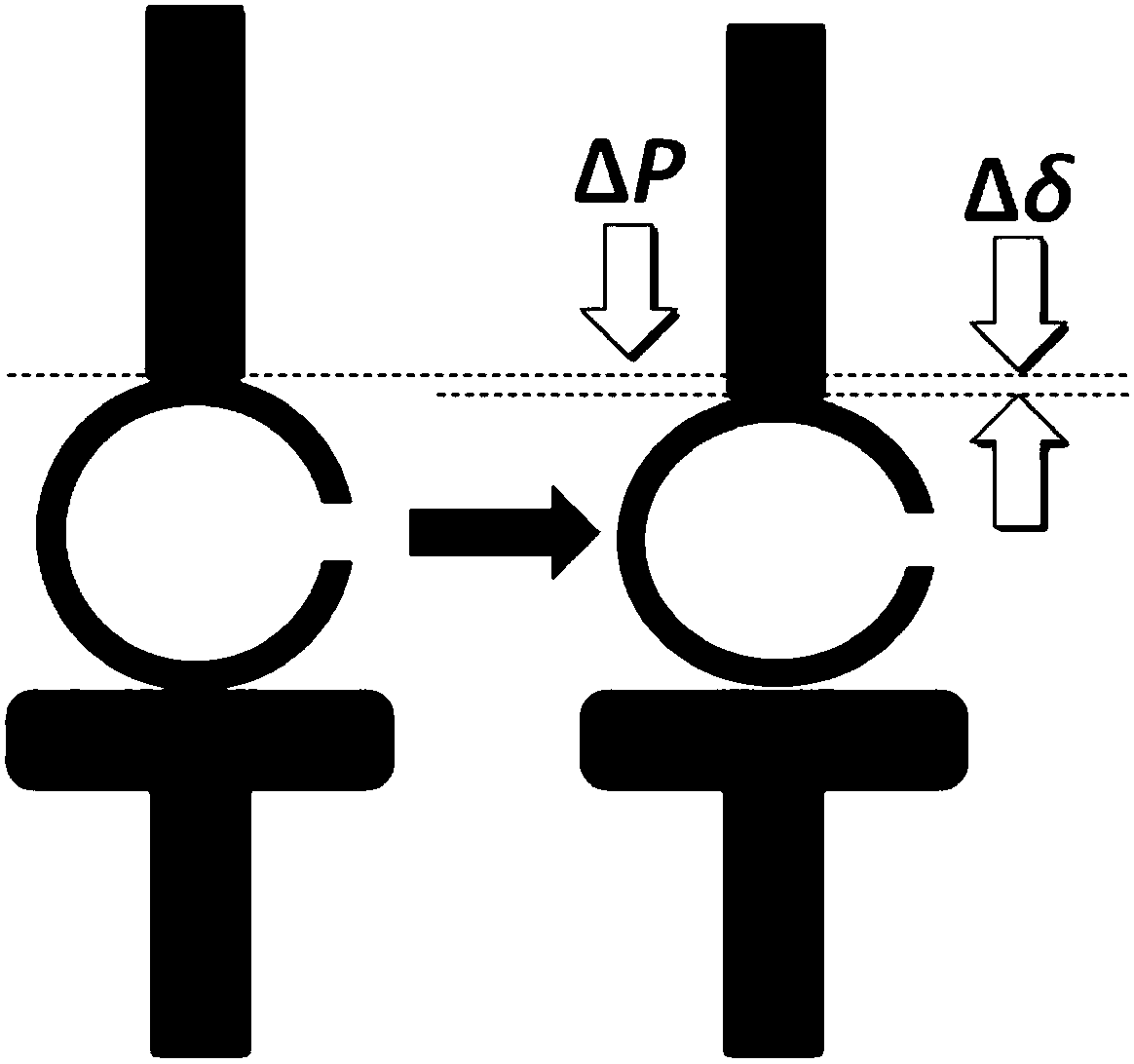

[0094] 3) Place the notched ring sample with the outer coating on the support table of the universal testing machine, and keep the notch at 1 / 2 of its height, and compress the sample at a loading rate of 0.1mm / min, The compression displacement variation of the no...

Embodiment 2

[0096] Embodiment 2: Measurement of elastic modulus of inner coating

[0097] 1) Remove the outer surface of C-SiC and the coating at the upper and lower ends by cutting to obtain a C-SiC pipe coating sample with an inner coating. Use a polishing machine to polish the surface, and then use a diamond blade to cut out a A notch with a width of about 2 mm to form a notched ring sample;

[0098] 2) Use a micrometer to measure the outer diameter of the notch ring sample R = 15.10mm, inner diameter rc = 11.95mm, width b = 7.14mm; use a digital microscope to measure the coating thickness h = 83μm; then the inner diameter of the substrate r = r c +h=12.033mm;

[0099] 3) Place the notched ring sample with the outer coating on the support table of the universal testing machine, and keep the notch at 1 / 2 of its height, and compress the sample at a loading rate of 0.1mm / min, The compression displacement variation of the notched ring sample between 4N and 10N (△P=6N) was measured by a h...

Embodiment 3

[0101] Embodiment 3: the measurement of elastic modulus of double-sided coating

[0102] 1) Remove the upper and lower coatings of C-SiC by grinding to obtain a double-sided coated C-SiC pipe coating sample, and then use a diamond blade to cut a gap with a width of about 2 mm to form a gap ring sample ;

[0103] 2) Use a micrometer to measure the outer diameter R of the notched ring sample c = 15.10mm, inner diameter r c = 11.95mm, width b = 7.14mm; using a digital microscope to measure the outer coating thickness h1 = 28μm, the inner coating thickness h 2=36μm; then the outer diameter of the substrate R=R c -h1=15.072mm, base inner diameter r=r c + h 2 =11.986mm;

[0104] 3) Place the notched ring sample with the outer coating on the support table of the universal testing machine, and keep the notch at 1 / 2 of its height, and compress the sample at a loading rate of 0.1mm / min, The compression displacement variation of the notched ring sample between 4N and 10N (△P=6N) w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com