Method for preparing tin oxide reinforced silver-based electrical contact materials

An electrical contact material, tin oxide technology, which is applied to contacts, circuits, electrical switches, etc., can solve the problems of increased material production scrap rate, poor processing performance, and rising production costs, so as to solve processing difficulties and reduce production costs. , The effect of improving the yield of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

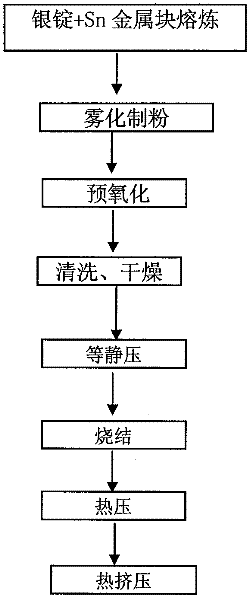

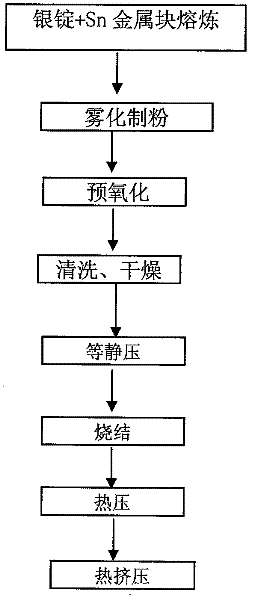

Method used

Image

Examples

Embodiment 1

[0032] Example 1 to prepare Ag-18SnO 2 material example

[0033] 1. Weigh 18Kg of silver ingot and 3.4Kg of Sn, and place them in an intermediate frequency induction furnace for melting. The melting temperature is 950°C;

[0034] 2. Then atomize powder, that is, use high-pressure nitrogen to impact and atomize the molten metal flow into small metal droplets, and then cool to obtain powder; the nitrogen pressure is 10MPa;

[0035] 3. Put the atomized powder into a high-pressure container and heat it to 850°C for pre-oxidation, the oxygen pressure is 0.1MPa, and oxidize for 10 hours;

[0036] 4. The oxidized powder is pickled with 5% hydrochloric acid with a mass ratio concentration. The cleaning time is 10 minutes. The mass of hydrochloric acid: the mass of powder = 1: 1, that is, the weight of hydrochloric acid is 18+4=22kg.

[0037] 5. Dry the cleaned powder in air. The drying temperature is 150° C. and the drying time is 12 hours.

[0038] 6. Press the oxidized powder i...

Embodiment 2

[0043] Example two to prepare Ag-3SnO 2 material example

[0044] 1. Weigh 25Kg of silver ingot and 0.6Kg of Sn, and place it in an intermediate frequency induction furnace for melting. The melting temperature is 1300°C;

[0045] 2. Then atomize powder, that is, use high-pressure nitrogen to impact and atomize the molten metal flow into small metal droplets, and then cool to obtain powder; the nitrogen pressure is 0.5MPa;

[0046] 3. Put the atomized powder into a high-pressure container and heat it to 450°C for pre-oxidation, the oxygen pressure is 3MPa, and oxidize for 1h;

[0047] 4. The oxidized powder is pickled with 20% hydrochloric acid with a mass ratio concentration, and the cleaning time is 5 minutes. The mass of hydrochloric acid: powder mass=1:5, and the weight of hydrochloric acid is (25+1)×1 / 5=5.2kg .

[0048] 5. Dry the cleaned powder in air. The drying temperature is 90°C and the drying time is 24h.

[0049] 6. Press the oxidized powder into a green body ...

Embodiment 3

[0054] Example three to prepare Ag-10SnO 2 material example

[0055] 1. Weigh 18Kg of silver ingot and 1.5Kg of Sn, and place them in an intermediate frequency induction furnace for melting. The melting temperature is 1100°C;

[0056] 2. Then atomize powder, that is, use high-pressure nitrogen to impact and atomize the molten metal flow into small metal droplets, and then cool to obtain powder; the nitrogen pressure is 4MPa;

[0057] 3. Put the atomized powder into a high-pressure container and heat it to 650°C for pre-oxidation, the oxygen pressure is 2MPa, and oxidize for 5h;

[0058] 4. The oxidized powder is pickled with 10% hydrochloric acid by mass ratio concentration, the cleaning time is 8 minutes, hydrochloric acid mass: powder mass=1:3, i.e. (18+2)×1 / 3=6.7kg hydrochloric acid.

[0059] 5. Dry the cleaned powder in air. The drying temperature is 100°C and the drying time is 18h.

[0060] 6. Press the oxidized powder into a green body under isostatic pressure of 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com