Negative Poisson's ratio high magnetostrictive material and its additive manufacturing method

A negative Poisson's ratio, additive manufacturing technology, applied in mechanical engineering, functional materials, material science intersection, additive manufacturing, information fields, can solve difficult processing, poor comprehensive mechanical properties of materials, unsatisfactory magnetostrictive effect, etc. problem, to achieve high magnetostrictive performance, improve comprehensive mechanical properties, and achieve the effect of magnetostrictive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

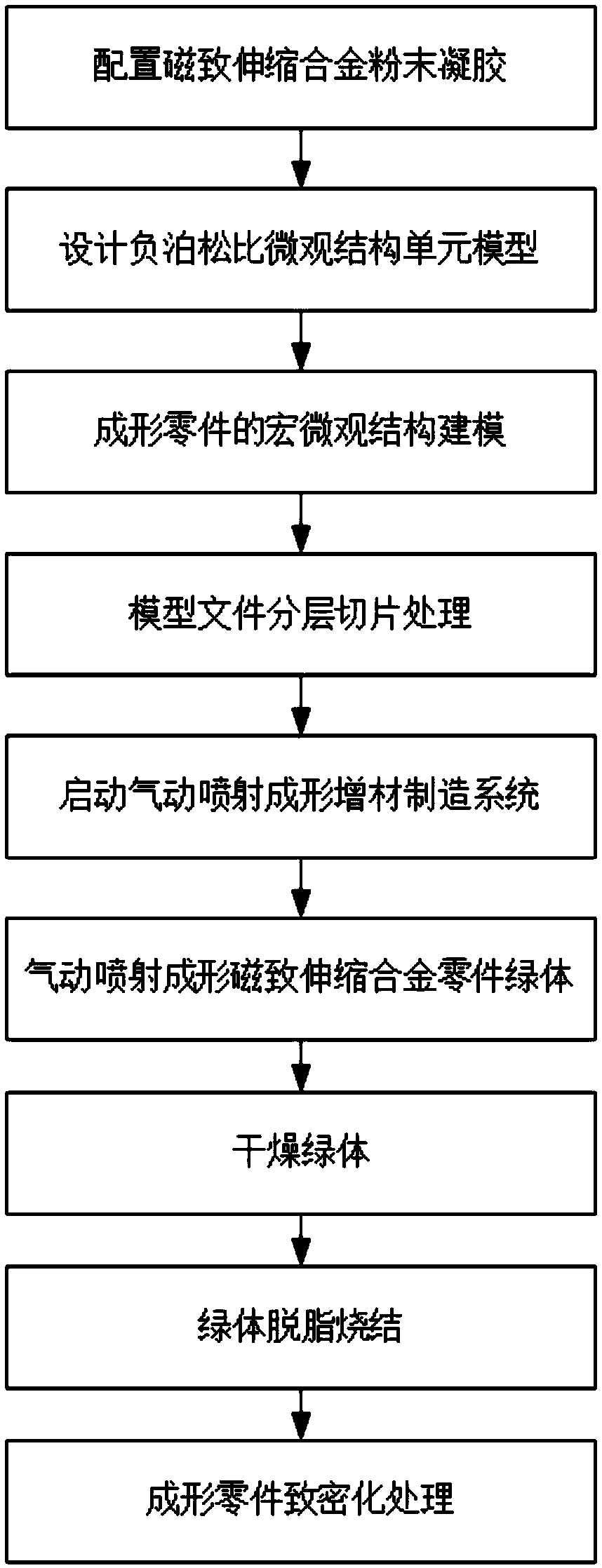

[0065] An ideal magnetostrictive material should have significant magnetostrictive properties, and the material has good comprehensive mechanical properties. The invention combines the magnetostrictive material with the negative Poisson's ratio structure, adopts the microstructure unit design with the Poisson's ratio less than -1, and can amplify the linear magnetostrictive effect and the bulk magnetostrictive effect of the material on demand, and adopts spray forming to increase the The material manufacturing technology can be used to form samples of any structure directly, and combined with the post-processing process, the comprehensive mechanical properties of the formed samples can be improved, so as to realize the additive manufacturing of magnetostrictive materials with high magnetostrictive properties.

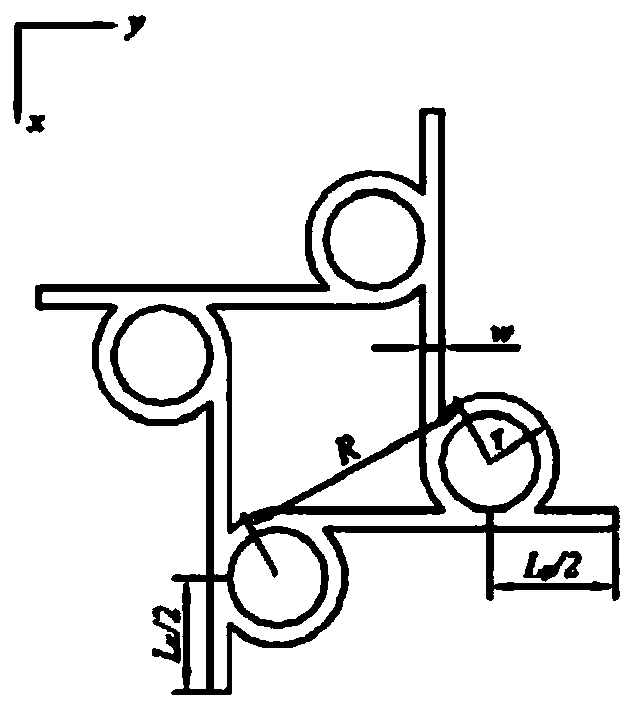

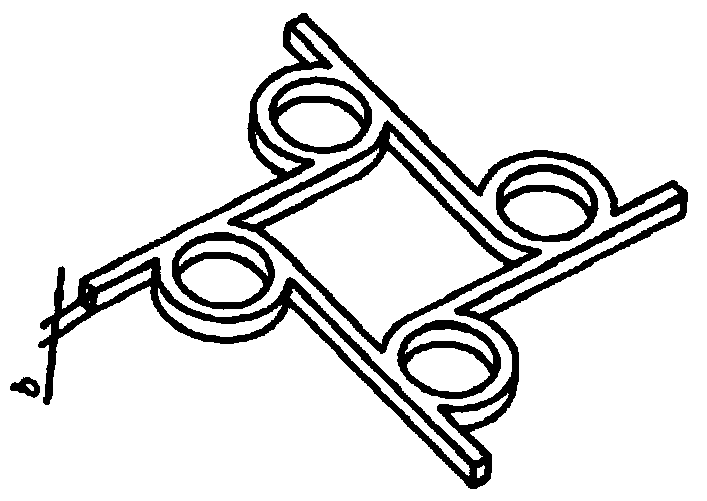

[0066] Negative Poisson's ratio high magnetostrictive material of the present invention, by Poisson's ratio less than-1, volume is 0.1-1mm 3 , the four-ligament isotrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com