A kind of color explosion-proof film and preparation method thereof

An explosion-proof film and color technology, applied in the direction of film/sheet adhesive, adhesive type, ester copolymer adhesive, etc. The effect of improving production efficiency, reducing processing difficulty and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

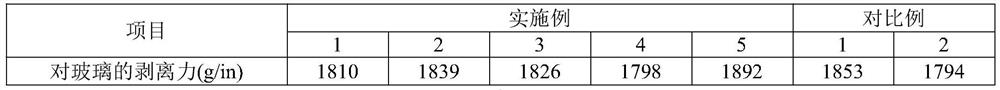

Examples

preparation example Construction

[0032] The preparation method of the colored explosion-proof film is as follows:

[0033] (1) Add acrylate, solvent, curing agent and colorant in sequence to the liquid mixing tank to prepare a coating solution with a solid content of 20-60%, stir for 10-60min, and then stand for 0.5-2h;

[0034] (2) Apply the prepared coating solution evenly on the surface of the PET film, and heat it at 60-140°C for 1-5min to obtain a colored adhesive layer;

[0035] (3) Attach the release film to the surface of the adhesive layer to ensure that there are no air bubbles in the attachment;

[0036] (4) curing the product prepared in step (3) at 40° C. for 2-4 days to obtain a colored explosion-proof film.

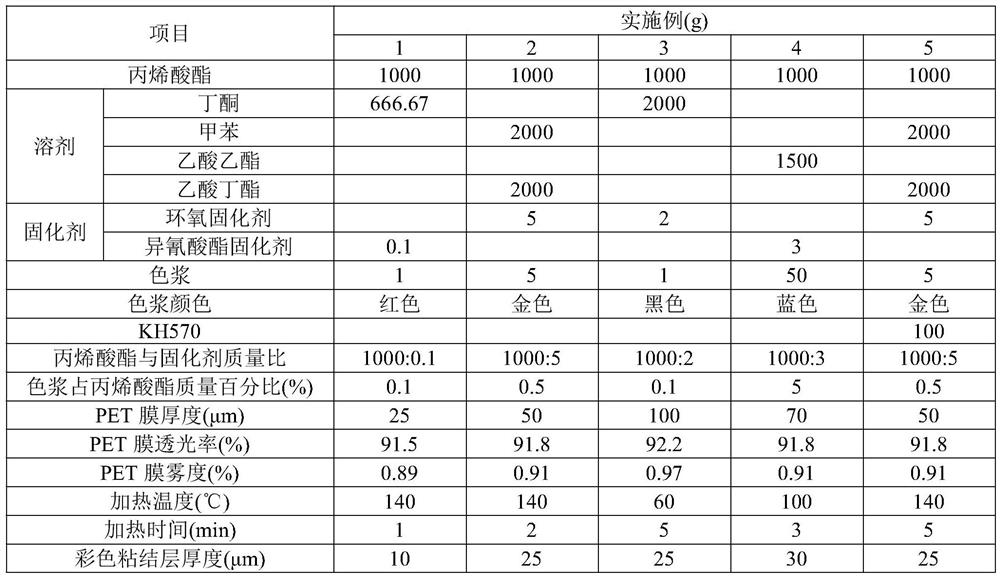

[0037] The parameters of Examples 1-5 are shown in Table 1.

[0038] Table 1

[0039]

[0040] Wherein, the color paste color is not limited to the several colors listed in Table 1, and various colors can be selected according to needs.

Embodiment 5

[0041] Example 5 After uniformly coating the prepared coating solution on the surface of the PET film in step (2), let it stand for 10 minutes before heating and subsequent treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com