Color explosion-proof film and preparation method thereof

An anti-explosion film and color technology, applied in the direction of film/sheet adhesive, adhesive type, non-polymer adhesive additive, etc., can solve the problems of low production efficiency and limited selection of electroplating colors, etc. Achieve the effects of improving production efficiency, solving difficult processing, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the colored explosion-proof film is as follows:

[0033] (1) Add acrylate, solvent, curing agent and colorant in sequence to the liquid mixing tank to prepare a coating solution with a solid content of 20-60%, stir for 10-60min, and then stand for 0.5-2h;

[0034] (2) Apply the prepared coating solution evenly on the surface of the PET film, and heat it at 60-140°C for 1-5min to obtain a colored adhesive layer;

[0035] (3) Attach the release film to the surface of the adhesive layer to ensure that there are no air bubbles in the attachment;

[0036] (4) curing the product prepared in step (3) at 40° C. for 2-4 days to obtain a colored explosion-proof film.

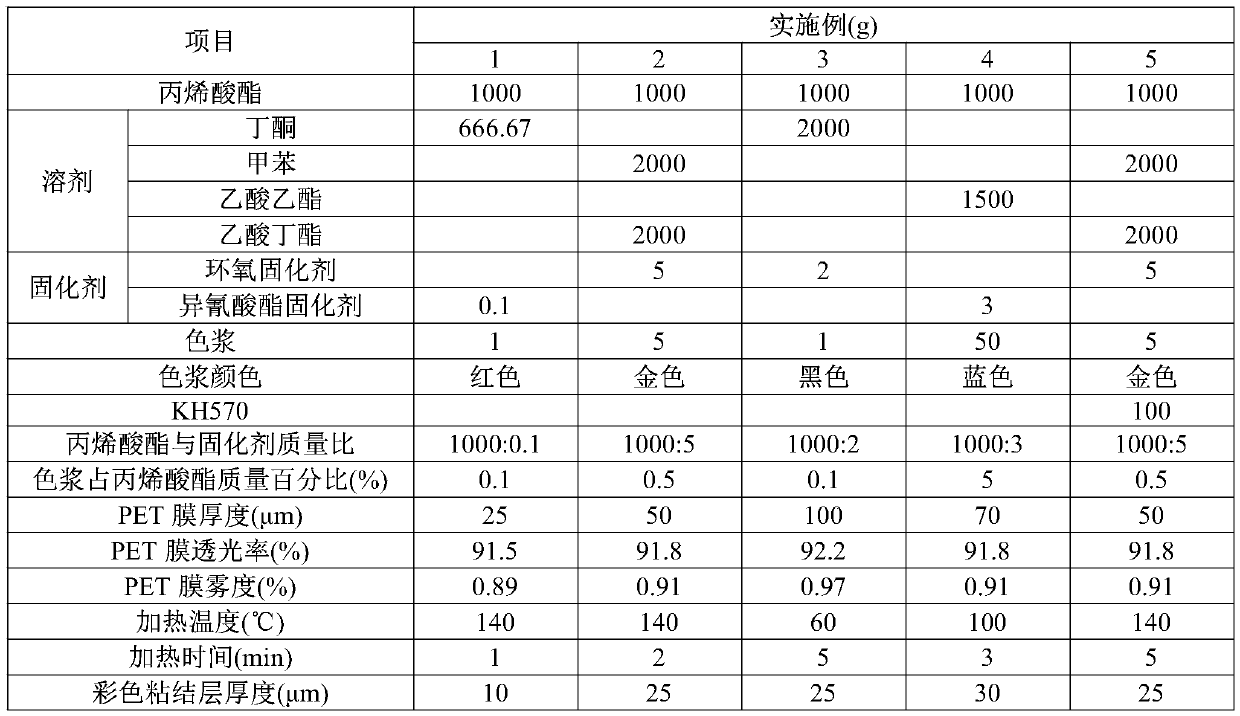

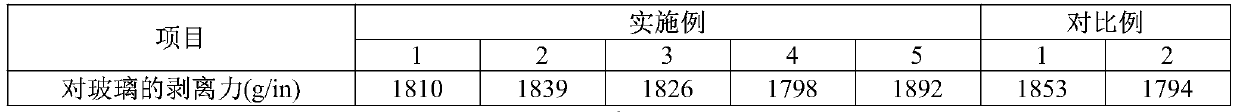

[0037] The parameters of Examples 1-5 are shown in Table 1.

[0038] Table 1

[0039]

[0040] Wherein, the color paste color is not limited to the several colors listed in Table 1, and various colors can be selected according to needs.

Embodiment 5

[0041] Example 5 After uniformly coating the prepared coating solution on the surface of the PET film in step (2), let it stand for 10 minutes before heating and subsequent treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com