Static pressure gas bearing used for free piston

A hydrostatic gas bearing and piston technology, applied in the field of bearing workpieces, can solve the problems of reduced gas film stiffness and bearing capacity, large diffusion effect, uneven gas film pressure distribution, etc., so as to improve stiffness and bearing capacity, improve Stability and longevity, the effect of eliminating diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereby.

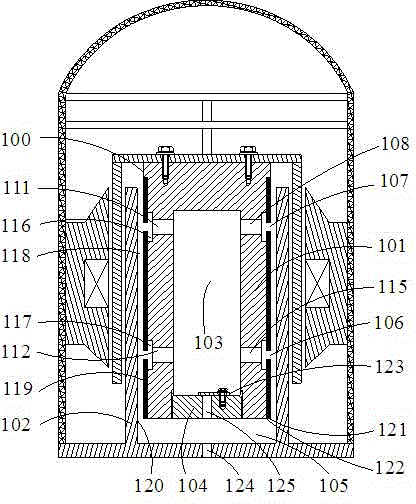

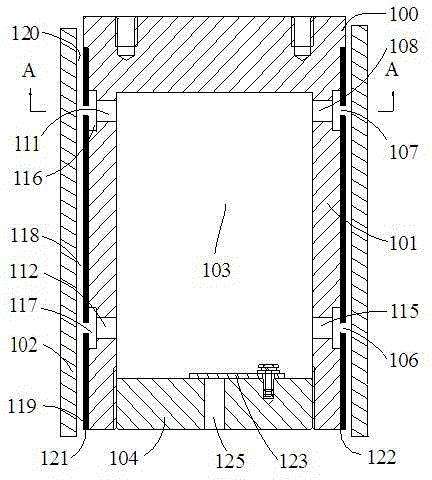

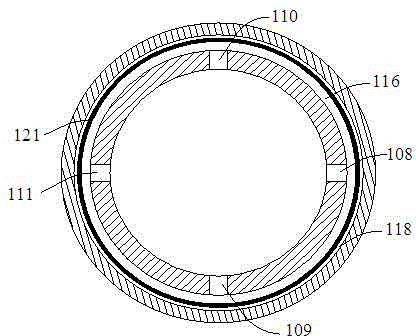

[0028] Please see first figure 1 , figure 2 , figure 1 It is a schematic diagram of an embodiment of a hydrostatic gas bearing for a free piston of the present invention, figure 2 It is a structural schematic diagram of the hydrostatic gas bearing used in the free piston of the present invention. As shown in the figure: a static pressure gas bearing for a free piston, including a piston 101, a cylinder 102, an air storage chamber 103, and a compression chamber 105, which is characterized in that two ends of the outer wall 122 of the piston 101 are respectively provided with two The annular air grooves 116, 117 parallel to and perpendicular to the center line of the piston 101 are respectively provided with four radial throttle holes 108-111, 112-115 on the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com