Novel electromagnetic sensor system for detecting steel wire rope defects

An electromagnetic sensor and wire rope technology, applied in the direction of material magnetic variables, etc., can solve the problems of inability to detect wire ropes, low detection accuracy, false detection and missed detection, etc., and achieve the effect of real-time processing and automatic non-destructive testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

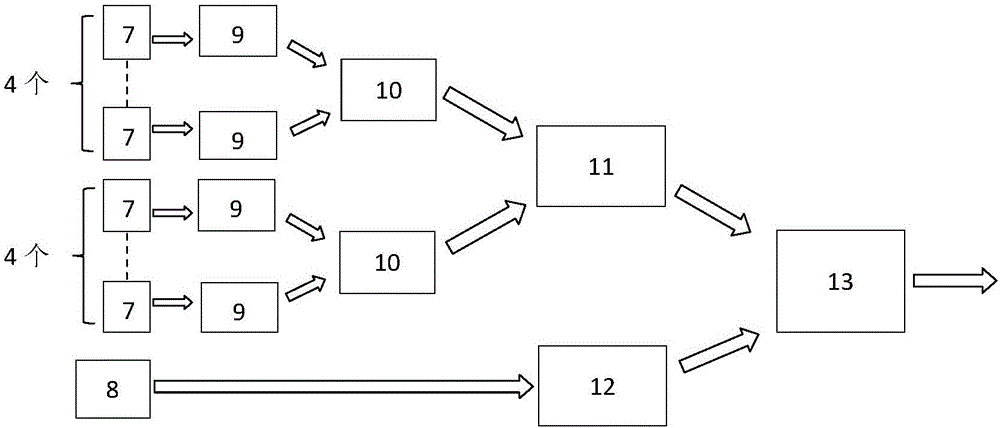

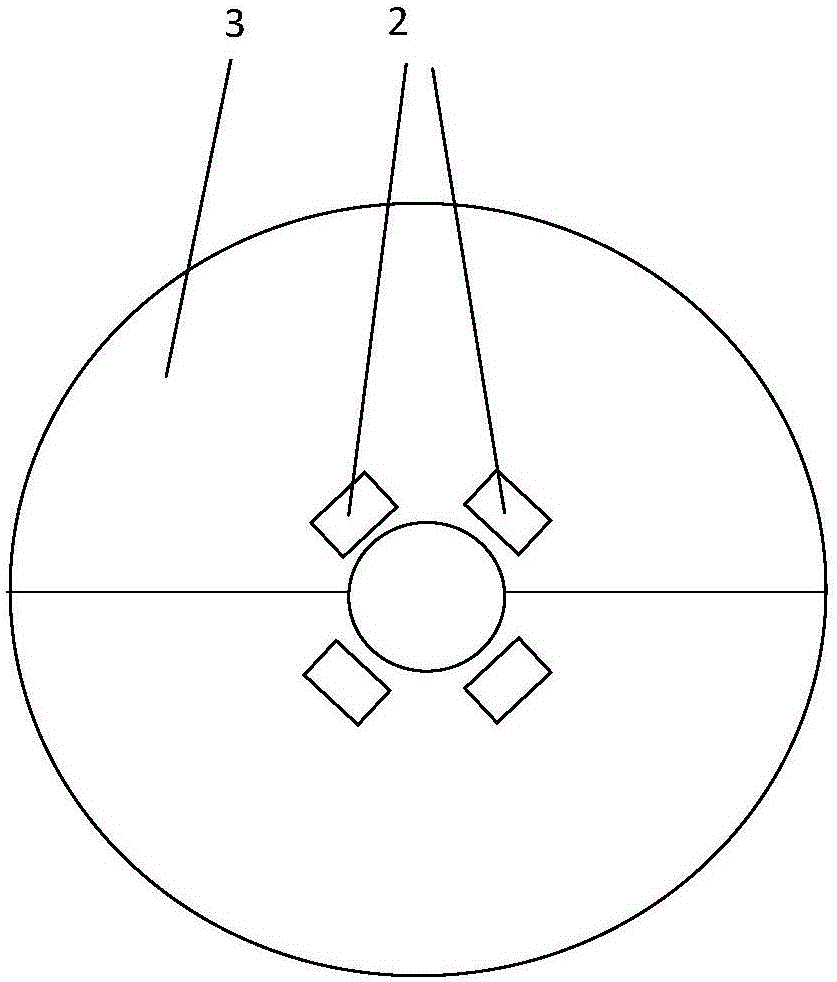

[0034] In the past, the sensor used a component to detect the defect. When the Hall element was used to detect the LMA signal, the detection signal was weak, and it was easily affected by the interference signal so that the detection effect was not obvious; while the induction coil was not sensitive, Therefore, when the induction coil is used to detect LF-type defects, the detection signal time is too short, the small defects cannot be identified, and the detection accuracy is not high. In order to overcome these shortcomings, this system uses two kinds of detection elements to realize the detection of two kinds of defects respectively, and analyzes and screens the detection signals through the subsequent circuit, so as to obtain the damage conditions of different types of defects.

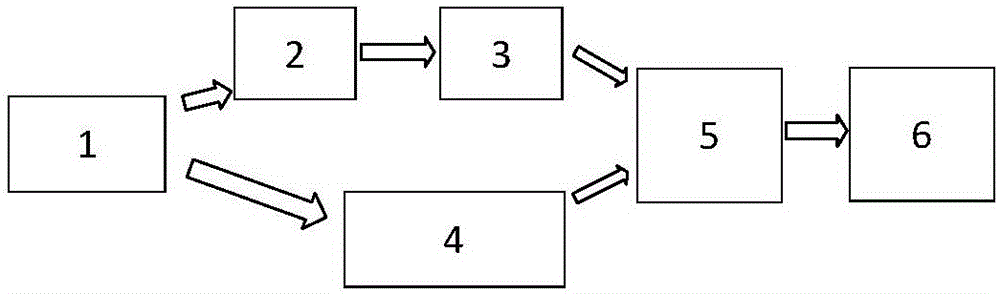

[0035]The novel electromagnetic sensor system for detecting steel wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com